English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

circuit breaker timing test

Understanding Circuit Breaker Timing Tests An Essential Component of Electrical Maintenance

Circuit breakers play a critical role in electrical systems, providing essential protection against overloads and short circuits. One key aspect of maintaining the reliability and efficiency of these devices is the timing test. This article delves into circuit breaker timing tests, their significance, and how they are conducted.

What is a Circuit Breaker Timing Test?

A circuit breaker timing test is a procedure used to measure the operation time of a circuit breaker when it is subjected to overcurrent or short-circuit conditions. This test is important because it evaluates how quickly the circuit breaker can respond to a fault, which directly impacts the protection of electrical equipment and personnel safety.

The timing test focuses on two main phases of the circuit breaker operation the opening time and the closing time. The opening time is the duration it takes for the breaker to disconnect the circuit after a fault is detected, while the closing time measures how quickly it can reseal the circuit when conditions return to normal.

Importance of Timing Tests

1. Safety Assurance The primary role of a circuit breaker is to prevent electrical overloads and faults from causing damage or hazards. By regularly conducting timing tests, maintenance teams can ensure that breakers will function correctly during emergency situations.

2. Equipment Protection Quick response times help to protect connected equipment from damage caused by electrical faults. A circuit breaker that trips too slowly may allow too much current to flow, potentially resulting in costly repairs or replacements.

3. System Reliability A reliable electrical system is essential for the smooth operation of any facility. Regular timing tests help to identify potential issues in circuit breakers before they affect the overall performance of the electrical system.

4. Compliance with Standards Many regulatory bodies and safety standards mandate routine testing of circuit breakers. Performing timing tests helps organizations meet compliance requirements and avoid penalties.

circuit breaker timing test

How is a Circuit Breaker Timing Test Conducted?

The testing process typically involves the following steps

1. Preparation Ensure that the breaker to be tested is de-energized and that the work area is safe. Gather the necessary testing equipment, which may include a timing test set, a test switch, and appropriate personal protective equipment (PPE).

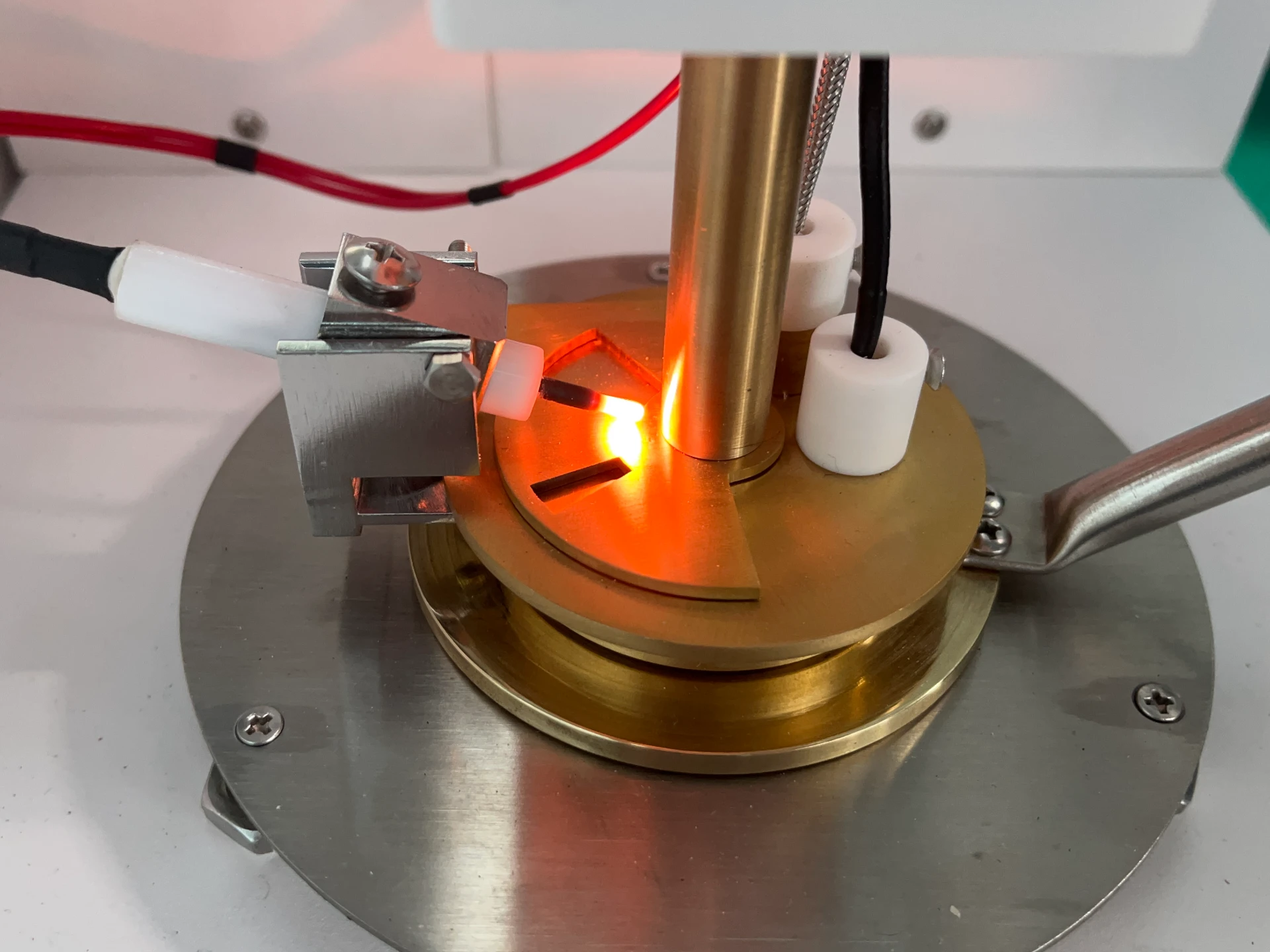

2. Connecting the Test Equipment Connect the timing test set to the circuit breaker. This equipment sends a trip signal to the breaker and records the time it takes for it to open or close.

3. Performing the Test Activate the test equipment to initiate a trip command. The timing device will measure the response time, capturing both opening and closing times. It’s important to perform multiple tests to ensure accuracy and consistency in the results.

4. Recording Results Document the timings recorded by the testing equipment. These results should be compared against the manufacturer’s specifications and industry standards. Any deviations from acceptable limits may indicate the need for maintenance or replacement.

5. Analysis and Maintenance Analyze the results to determine if the circuit breaker is functioning within acceptable parameters. If the timing is off, a thorough examination of the breaker may be necessary to identify underlying issues such as wear, mechanical failure, or calibration errors.

Conclusion

Circuit breaker timing tests are a vital aspect of electrical maintenance and safety. By routinely assessing the operational performance of circuit breakers, facility managers can ensure the reliability of their electrical systems and protect sensitive equipment from potential damage. Incorporating these tests into a comprehensive maintenance program not only helps meet compliance standards but also enhances overall safety in any electrical environment. As technology continues to advance, the methods and tools used for timing tests will likely evolve, further increasing the effectiveness of this critical maintenance practice.

-

Ensuring Transformer Reliability with High-Precision Turns Ratio TestingNewsJul.18,2025

-

Ensuring SF₆ Gas Safety: Introducing PUSH’s Integrated SF₆ Analyzer for Dew Point, Purity, and Decomposition MonitoringNewsJul.10,2025

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025