English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

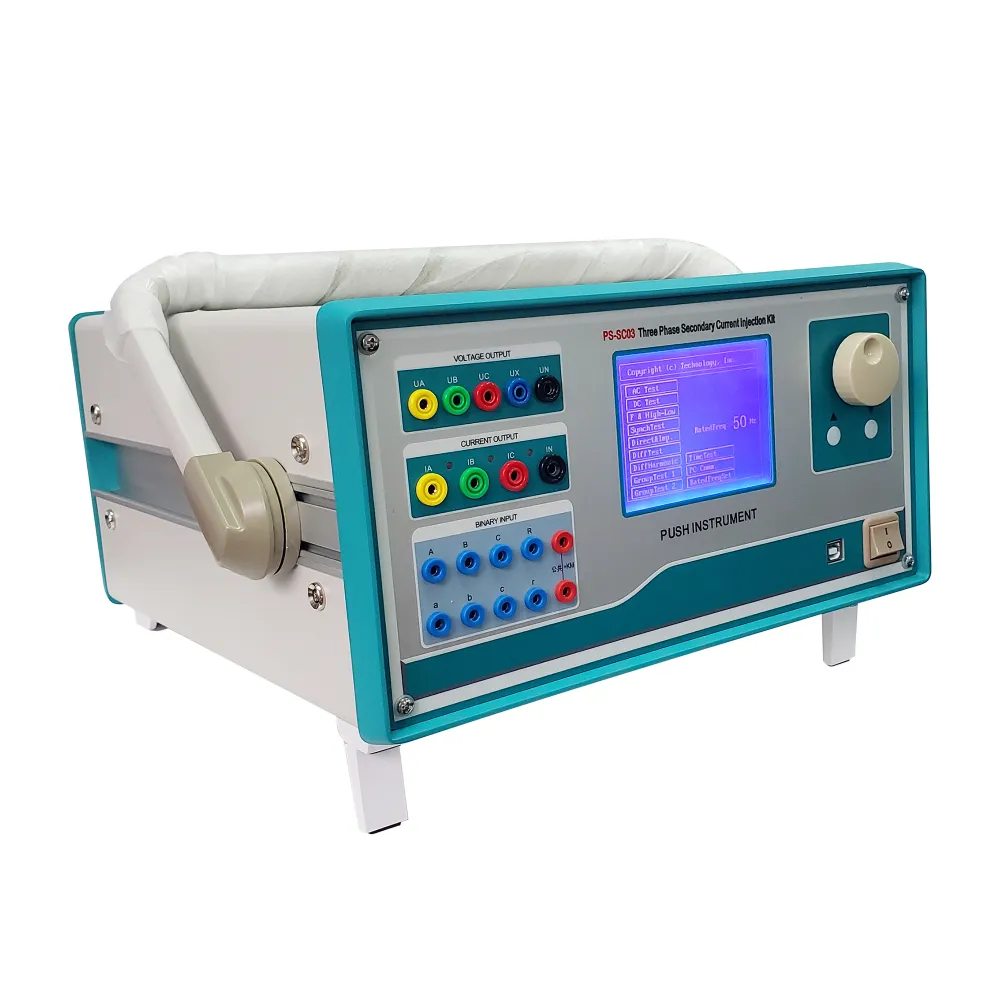

protection relay testing equipment

Testing Equipment for Protection Relays Ensuring Reliability and Safety in Power Systems

Protection relays play a crucial role in safeguarding electrical systems by detecting faults and initiating actions to isolate faulty components. Ensuring the reliability and accuracy of these protection devices is paramount, as any malfunction could lead to catastrophic failures, equipment damage, or even safety hazards. This is where specialized testing equipment for protection relays comes into play. This article discusses the importance of testing equipment, its functions, and the advancements in technology that have enhanced the testing process.

The Importance of Testing Protection Relays

Protection relays are designed to monitor electrical parameters and execute specific functions when conditions deviate from the norm. They help in the protection of generators, transformers, and transmission lines by disconnecting the faulty section from the system. Regular testing is essential to ensure that these relays operate correctly when called upon.

Testing protection relays involves simulating fault conditions and measuring the response of the relay. This verification process is critical for utilities and industrial facilities to ensure their protection schemes work as intended. Neglecting to test these devices can lead to undetected malfunctions, which could have severe repercussions.

Types of Testing Equipment

Several types of testing equipment are commonly used for protection relay testing, each designed for specific testing needs

1. Primary Injection Test Sets These devices are employed to inject high-current signals directly into the protection relay. This method proves particularly useful for testing relays that require an actual current input to verify their operation. Primary injection testing provides a realistic assessment of relay performance under working conditions.

2. Secondary Injection Test Sets In contrast to primary injection testing, secondary injection test sets simulate the normal operating conditions without the need for high currents. They allow testers to apply virtual scenarios, including voltage, current, frequency, and power factor, to evaluate relay operation.

protection relay testing equipment

3. Automated Testing Systems With the advancement of technology, automated test systems are becoming more prevalent. These systems can conduct a series of tests, collect data, and analyze results without significant human intervention. Automation helps reduce the potential for human error and accelerates the testing process.

4. Software-Based Testing Solutions Many modern testing devices come with software that provides advanced simulation capabilities, comprehensive reporting, and data analysis. These tools can create complex fault scenarios and visualize relay performance, making it easier to understand how the device will react in real-time situations.

Advancements in Testing Technology

The realm of protection relay testing equipment has seen significant advancements in recent years. Enhanced measurement accuracy, greater portability, and user-friendly interfaces are some of the key improvements. Manufacturers now provide compact devices that can fit easily into fieldwork, allowing engineers to perform tests onsite without the need for bulky equipment.

Moreover, the integration of communication protocols such as IEC 61850 has revolutionized the interaction between testing equipment and protection relays. This standard enables seamless data exchange, facilitating more sophisticated testing and validation processes. Engineers can now assess the performance of digital relays and smart grid technologies comprehensively.

Conclusion

In conclusion, the testing of protection relays is vital to maintaining the integrity and reliability of electrical systems. As power grids become more complex with the integration of renewable energies and smart technologies, the need for robust testing measures cannot be overstated. Testing equipment for protection relays has evolved to meet these demands, providing utilities and industries with the tools necessary to ensure safety and reliability.

By adopting advanced testing technologies, organizations can significantly reduce the risk of failures and enhance the operational efficiency of their electrical systems. Routine testing not only safeguards infrastructure but also contributes to the overall resilience of modern power networks. In an age where energy dependency is paramount, investing in quality testing equipment for protection relays is not just a best practice; it’s a critical component of sustainable energy management.

-

Ensuring Transformer Reliability with High-Precision Turns Ratio TestingNewsJul.18,2025

-

Ensuring SF₆ Gas Safety: Introducing PUSH’s Integrated SF₆ Analyzer for Dew Point, Purity, and Decomposition MonitoringNewsJul.10,2025

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025