English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

tan delta test for ct

Understanding the Tan Delta Test for Capacitor Transformers

The Tan Delta Test, also known as the Power Factor Test, is a vital diagnostic tool in the maintenance and assessment of capacitor transformers (CTs). These devices, crucial in the electrical power supply chain, require stringent monitoring to ensure their integrity and reliability. The Tan Delta Test serves as an effective method to evaluate the insulation health of these transformers, helping engineers identify potential issues that could lead to failures.

What is Tan Delta?

Tan Delta (tan δ) is a parameter that measures the power factor of insulation materials, defined as the ratio of resistive current to capacitive current in the dielectric insulation. In simpler terms, it quantifies how much current is lost due to the resistance of the insulating material compared to the total current flowing through it. The test is based on the principle that the insulation system will exhibit some degree of conductivity over time, especially if it is aged or contaminated.

The Tan Delta angle corresponds to the energy losses in insulation. A lower angle suggests that insulation is functioning well, while a higher angle indicates increased losses, which can be a sign of insulation deterioration.

The Importance of Tan Delta Testing

For capacitor transformers, performing a Tan Delta Test is essential for several reasons

1. Early Detection of Insulation Degradation The test allows for the early detection of problems such as moisture ingress, insulation breakdown, and contamination. Identifying these issues at an early stage can prevent catastrophic failures and costly downtime.

2. Performance Monitoring Regular Tan Delta measurements help in monitoring the performance of the transformer insulation over time. Trends in tan δ values can reveal the degradation rate of the insulation and help inform maintenance schedules.

3. Quality Assurance During the manufacturing process of capacitor transformers, Tan Delta Testing can be employed as a quality control measure to ensure that insulation materials meet the required specifications.

4. Compliance with Standards Many industry standards and guidelines recommend or require Tan Delta Testing for electrical equipment. Compliance not only guarantees operational safety but also helps in ensuring liability coverage under insurance policies.

How is the Test Conducted?

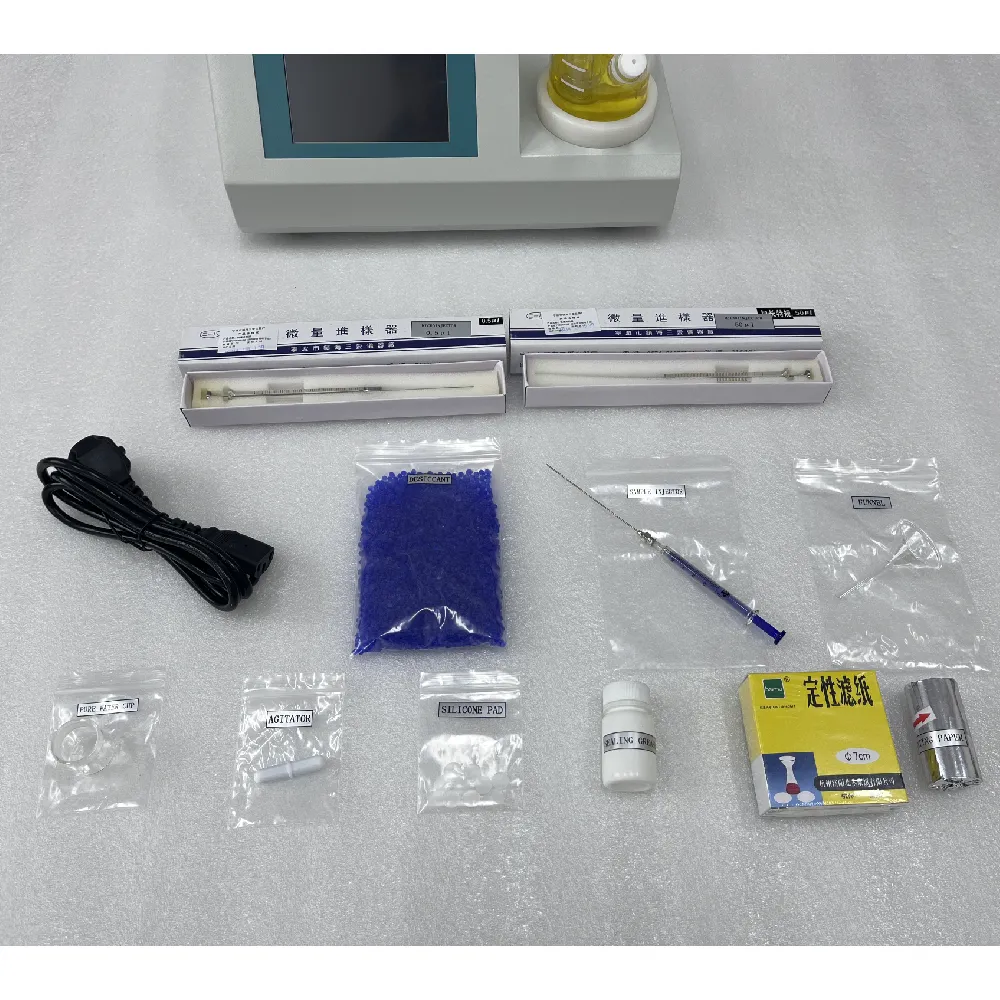

tan delta test for ct

The Tan Delta Test is typically conducted under controlled conditions with the transformer de-energized

. The standard procedure includes the following steps1. Preparation The transformer is disconnected from the power system. All necessary safety precautions are taken to ensure a safe testing environment.

2. Connection The test equipment is connected to the high-voltage and ground terminals of the transformer. Specialized test sets may apply a high voltage AC signal to the transformer.

3. Data Collection The test equipment measures the current flowing through the insulation and calculates the Tan Delta value. This process generally involves varying the frequency of the test signal to monitor how the dielectric reacts.

4. Analysis The collected data is analyzed against industry standards and historical data. A trend analysis can provide insights into the health of the insulation.

5. Reporting Finally, the result is documented along with any recommendations for further action if necessary.

Interpretation of Results

Tan Delta values are usually expressed as a percentage. A typical range for healthy insulation is below 0.5%. Values between 0.5% and 1.0% may indicate the presence of some insulation issues, while values above 1.0% are generally considered unacceptable and warrant immediate attention.

It’s important to interpret these values in conjunction with other diagnostic tests, like capacitance tests or insulation resistance measurements, to provide a comprehensive picture of transformer health.

Conclusion

The Tan Delta Test is an invaluable tool for ensuring the longevity and reliability of capacitor transformers. By understanding and employing this testing method, utilities and facility managers can mitigate risks associated with transformer failures, thereby ensuring that electrical power systems operate smoothly and efficiently. As technology advances, the methods and equipment used for Tan Delta Testing continue to evolve, making it even easier to maintain the critical infrastructure that supports modern society’s electrical needs. Emphasizing the importance of regular assessments can help secure more reliable energy delivery for years to come.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025