English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

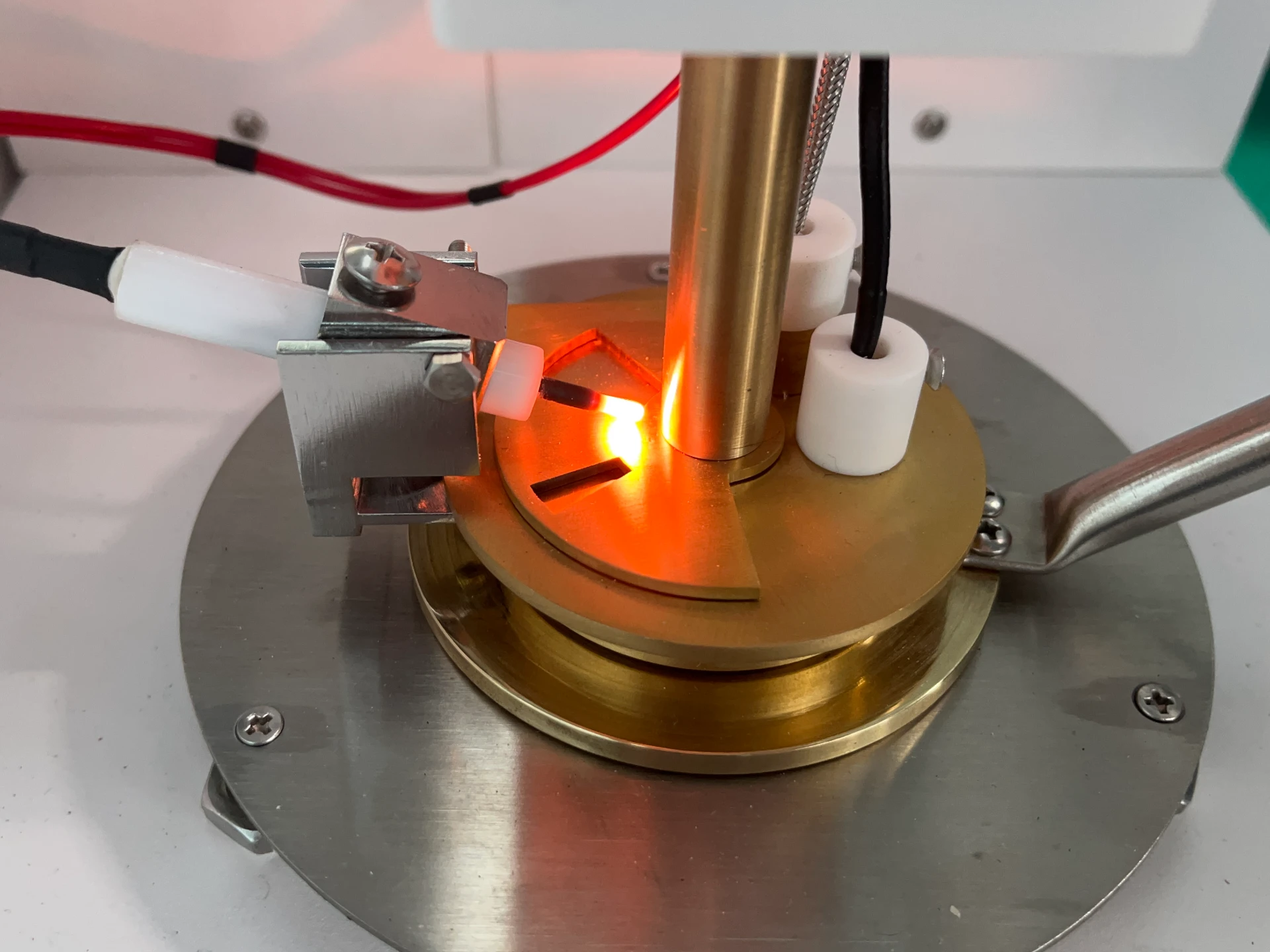

double distillation apparatus

Double Distillation Apparatus An Overview

Double distillation is a fundamental technique widely employed in chemistry and industrial processes to purify liquids or separate components based on differences in boiling points. The double distillation apparatus is specifically designed to enhance the efficiency of the distillation process, allowing for the production of highly purified substances. This article delves into the operational principles, applications, and advantages of the double distillation apparatus.

Operational Principles

The essence of distillation lies in the phase change of substances from liquid to vapor and subsequently back to liquid. In a typical double distillation setup, the process begins with heating the mixture in a distillation flask. As the temperature rises, components with lower boiling points vaporize first. These vapors are channeled into a condenser, where they cool down and revert to liquid form, collected in a separate receiving flask.

In double distillation, the distillation process is repeated to improve purity. The first distillation removes a significant portion of the impurities, while the second distillation focuses on achieving a higher degree of purity by capturing the most volatile components. This two-step process involves the use of two distinct distillation units—one for the initial distillation and another for the secondary refinement, which can be either a simple apparatus or a more complex fractional distillation setup.

Components of a Double Distillation Apparatus

A typical double distillation apparatus consists of several key components

2. Heating Source A heat source, such as a Bunsen burner or heating mantle, is necessary to provide sufficient energy to vaporize the liquid.

3. Condenser The condenser, which is cooled by water circulation, facilitates the transition of vapor back to liquid. As vapor enters from the heating flask, it cools down in the condenser and is collected in the receiving flask.

double distillation apparatus

4. Receiving Flask This is where the condensed liquid, or distillate, is collected after each distillation step.

5. Thermometer A thermometer is typically situated at the top of the distillation flask to monitor the temperature accurately, ensuring optimal separation of components.

6. Distillation Column In some setups, a distillation column may be integrated to provide additional surface area for vapor-liquid contact, further promoting separation during the second distillation.

Applications

Double distillation is extensively used in laboratories and industries. In the chemical industry, it is crucial for producing high-purity solvents, essential oils, or alcohols. In the pharmaceutical industry, it is used to purify solvents for drug synthesis, ensuring that no residual impurities compromise the quality of the final product.

Additionally, double distillation plays a role in the production of essential oils and fragrances, where maintaining the quality and integrity of the product is paramount. This technique is also applicable in the food and beverage sector, particularly in the refinement of products like whiskey, where flavor profiles must be preserved while removing unwanted components.

Advantages

The primary advantage of using a double distillation apparatus is the superior purity achieved through its two-step process, which significantly reduces contamination from impurities. This results in higher-quality end products, making it an invaluable method for various applications. Furthermore, the double distillation process can be economically viable for large-scale operations, as it allows for the efficient recovery of solvents and other valuable components.

In conclusion, the double distillation apparatus is a critical tool in both academic research and industrial applications. By enhancing the purity of liquids through a systematic two-step process, it remains an essential method for chemical separation and purification, demonstrating its broad significance across multiple fields.

-

Transformer Test Essentials: Insulating Oil Tester and TypesNewsMay.30,2025

-

Grease Testers and Oil Determination OverviewNewsMay.30,2025

-

Exploring Electricity Usage Testers and GeneratorsNewsMay.30,2025

-

Essential Guide to Transformer Oil Testing ToolsNewsMay.30,2025

-

Ensuring Safety with a Circuit Breaker FinderNewsMay.30,2025

-

Electrical Safety Tools Hipot, Dielectric, VLF TestersNewsMay.30,2025