English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

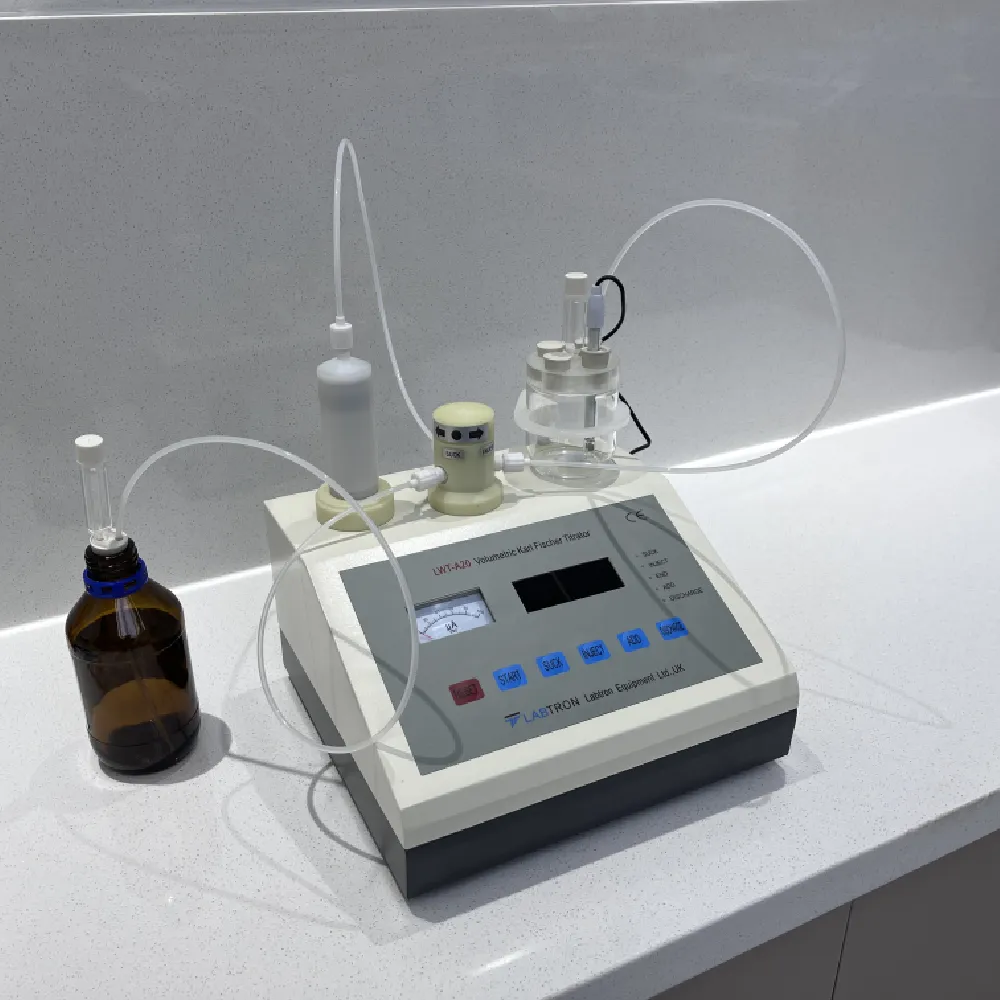

dielectric strength tester

Understanding the Dielectric Strength Tester A Critical Tool in Electrical Safety

In the realm of electrical engineering and safety testing, the dielectric strength tester plays a crucial role. This specialized device is designed to evaluate the insulation properties of materials and components, ensuring that they can withstand high-voltage conditions without failure. In this article, we will explore the significance, functioning, and applications of dielectric strength testers.

What is Dielectric Strength?

Dielectric strength refers to the maximum electric field that a material can withstand without experiencing breakdown. Essentially, it measures the ability of an insulating material to resist electric current. When the voltage applied to an insulating material exceeds its dielectric strength, the material begins to conduct electricity, which can lead to catastrophic failure of electrical components or systems. Therefore, assessing dielectric strength is vital in preventing electrical failures that could result in equipment damage, safety hazards, or even human fatalities.

The Importance of Dielectric Strength Testing

Dielectric strength testing is essential across various industries, including electrical, electronics, aerospace, and automotive. By determining the dielectric strength of insulation materials and electric components, manufacturers can ensure that their products meet safety standards and regulatory requirements. This testing helps prevent insulation failure, which can result in short circuits, fires, and equipment damage. Moreover, compliance with industry standards such as IEC, ASTM, and UL enhances product reliability and instills consumer confidence.

How Does a Dielectric Strength Tester Work?

A dielectric strength tester typically applies a high voltage across the material being tested while measuring the resulting current. The device increases the voltage gradually until it reaches the material's breakdown point. The dielectric strength is calculated as the voltage at which breakdown occurs divided by the thickness of the insulating material. This measurement is usually expressed in volts per mil (V/mil) or kilovolts per millimeter (kV/mm).

There are various types of dielectric strength testers, including

dielectric strength tester

1. AC Dielectric Testers These testers apply an alternating current voltage to the material. They are commonly used for assessing the insulation of wires and cables, transformers, and other electrical devices.

2. DC Dielectric Testers These devices use direct current voltage, which can provide more accurate measurements for certain materials and applications.

3. Impulse Dielectric Testers Used for testing materials under sudden voltage spikes, commonly seen in surge protection applications or during lightning strikes.

Each type of tester has its specific applications and advantages, and the choice often depends on the material being tested and the required safety standards.

Applications of Dielectric Strength Testers

The applications of dielectric strength testers are widespread. In the electrical industry, these testers are used to assess the insulation of wires, cables, transformers, and electrical devices. In the manufacturing sector, materials such as plastics, rubber, and composites are tested for their insulation properties. The automotive and aerospace industries rely on dielectric strength testing for electronic components, ensuring that they function safely under high-voltage conditions.

In the healthcare sector, dielectric strength testing is critical for medical devices that rely on electrical insulation to ensure patient safety. This testing minimizes the risk of electric shocks and equipment malfunctions in sensitive environments like hospitals.

Conclusion

In summary, the dielectric strength tester is an invaluable tool in ensuring the safety and reliability of electrical systems and components. By assessing the dielectric strength of materials, industries can prevent electrical failures that could have catastrophic consequences. As technology continues to advance, the importance of dielectric strength testing will only grow, underpinning the need for robust electrical safety measures across all sectors. As engineers and manufacturers prioritize safety and compliance, the dielectric strength tester will remain a critical asset in the pursuit of high-quality electrical products.

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025