English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Evaluating Transformer Oil Quality Through Comprehensive Testing Methods and Techniques

Transformer Oil Testing Ensuring Efficiency and Safety in Electric Power Systems

Transformer oil, a crucial component in the operation of electrical transformers, serves the dual purposes of insulation and cooling. As the backbone of the generative and distribution aspects of modern electrical grids, transformers must function efficiently to reduce operational failures and maintain a steady flow of electricity. Consequently, transformer oil testing is an essential practice that ensures the reliability, longevity, and safety of these critical systems.

Importance of Transformer Oil

Transformer oil, often referred to as mineral oil, possesses excellent dielectric properties, which are vital for preventing electrical discharges within transformers. Additionally, it facilitates heat dissipation, thereby maintaining optimal operating temperatures. Over time, though, transformer oil can degrade due to various factors, including exposure to air, moisture, and contaminants. Therefore, periodic testing of transformer oil is imperative to assess its health and performance characteristics.

Key Testing Parameters

There are several critical parameters that transformer oil testing typically evaluates

1. Dielectric Strength This is a measure of the oil's ability to resist electrical breakdown. High dielectric strength indicates that the oil can effectively insulate the transformer components, while a decline in this property signals potential risks of failure. Routine dielectric strength tests can prevent transformers from operating under unsafe conditions.

2. Moisture Content Water infiltration into transformer oil can severely impair its insulating capabilities. Testing for moisture levels is crucial since even minute amounts of water can drastically affect the performance of the transformer. This testing is typically conducted using Karl Fischer titration, which offers accurate moisture measurement.

3. Furan Analysis Furan compounds can indicate the degree of insulation degradation within the transformer. The presence of furan in transformer oil tests can provide insights into the thermal and electrical stress the insulating materials have undergone.

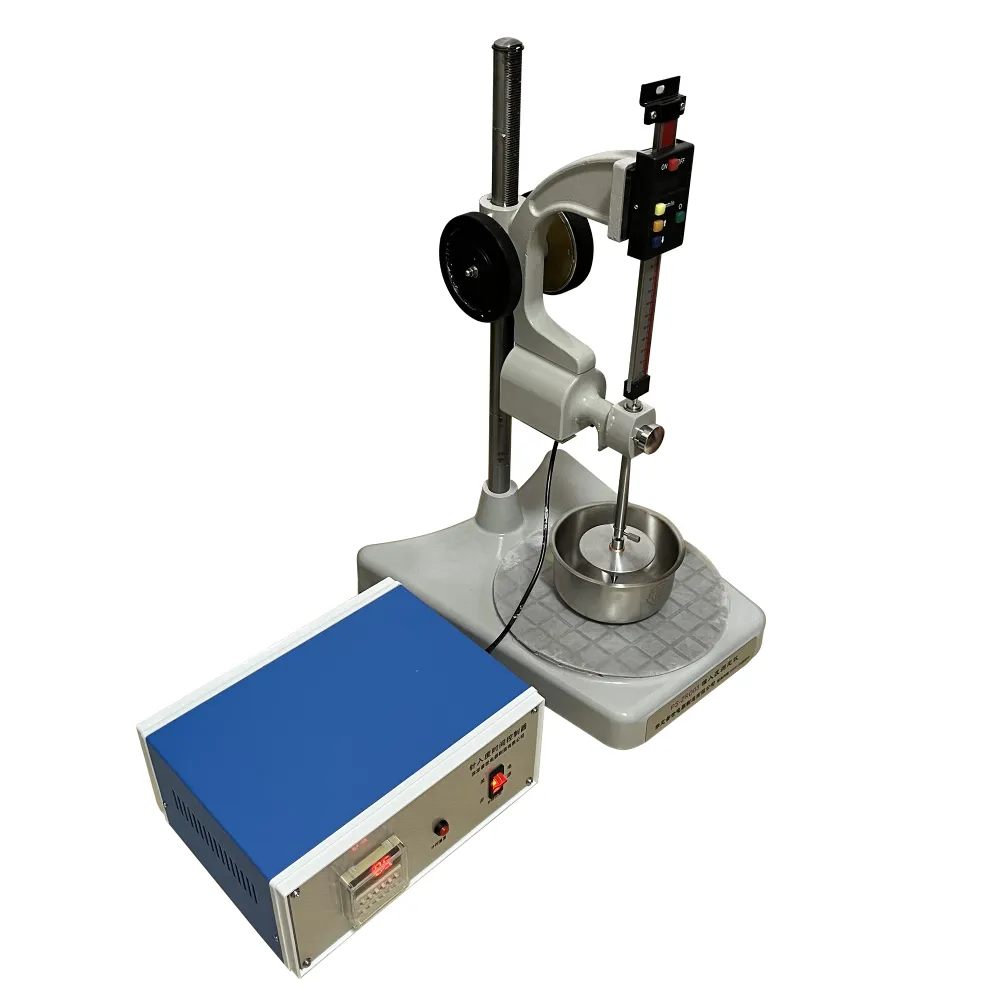

transformer oil testing

4. Acidity and Neutralization Number Over time, transformer oil can become acidic due to oxidation and the breakdown of its components. Increased acidity can lead to corrosion of metal parts within the transformer. Testing the acidity levels helps in assessing the oil's condition and operational viability.

5. Dielectric Loss Factor This parameter measures the energy lost as heat within the insulating oil when it is subjected to an alternating electric field. High values of the dielectric loss factor signify aging and poor condition of the oil, which necessitates replacement.

6. Flash Point The flash point of transformer oil is critical for safety reasons, as it indicates the temperature at which the oil could ignite. Oil with a lower flash point poses a higher risk of fire hazards. Regular testing ensures that the oil remains within safe operational parameters.

Testing Methods

Transformer oil testing can be performed using various methods, ranging from basic field tests to sophisticated laboratory analyses. Field tests provide quick results for vital parameters like dielectric strength and moisture content, which help in immediate decision-making. In contrast, laboratory tests, such as furan analysis and complete chemical composition checks, offer thorough insights into the oil's general health.

Conclusion

Transformer oil testing is an indispensable aspect of maintenance within the electrical power industry. By ensuring that transformer oil remains within appropriate quality levels, utilities can enhance the reliability and operational efficiency of transformers, significantly reducing the risk of outages and failures. Regular testing not only prolongs the life of transformer units but also safeguards personnel and property against potential hazards associated with transformer oil degradation.

As electrical systems continue to evolve with advancing technology and greater demand for efficient energy distribution, the significance of transformer oil testing will only increase. Implementing a robust testing program, coupled with proper maintenance strategies, is crucial for the sustainability of modern power systems. With safety and reliability in mind, transformer oil testing will remain a cornerstone of effective electrical engineering practices.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025