English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

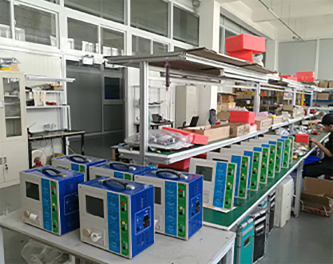

flash point machine

Understanding Flash Point Machines A Vital Tool for Safety in the Laboratory

In various industries, particularly those dealing with chemicals, ensuring safety standards is imperative to prevent accidents and injuries. One of the crucial parameters in assessing the hazards associated with flammable substances is the flash point. A flash point machine is an essential apparatus that measures the lowest temperature at which a liquid can vaporize to form an ignitable mixture in air. This article explores the significance of flash point machines, their operating principles, and their importance in risk management.

What is Flash Point?

Flash point is a critical property of flammable and combustible liquids. It defines the temperature at which enough vapor is generated above a liquid to create a mixture with air that can ignite. Understanding the flash point is vital for risk assessment in workplaces that handle hazardous materials. For instance, different substances have varying flash points; gasoline has a low flash point, making it highly volatile and dangerous, while some oils have higher flash points, thus being safer to handle at ambient temperatures.

Functionality of Flash Point Machines

Flash point machines, also known as flash point testers, are designed to take precise measurements of the flash point of a liquid sample. They operate based on two primary testing methods open cup and closed cup testing.

1. Open Cup Method In this method, the liquid is placed in an open container, and a heat source is applied. As the temperature rises, a flame is introduced to the vapor above the liquid. If the vapor ignites, the temperature at which this occurs is recorded as the flash point. This method is typically used for substances with higher flash points.

2. Closed Cup Method This testing method involves an enclosed container where the liquid is heated. The vapors are contained, which allows for more accurate measurements of lower flash points. Similar to the open cup method, a flame is introduced, and the temperature at which ignition occurs is recorded. This method is preferred for most laboratory applications since it offers safer and more reliable results.

Importance of Flash Point Measurement

The significance of flash point measurement cannot be overstated. Knowledge of a substance's flash point helps organizations comply with safety regulations set by government agencies. This is crucial for

- Storage and Transportation Understanding the flash point aids in the proper classification of chemicals, influencing how they should be stored and transported. For example, substances with low flash points may require special containers or temperature controls during transit.

flash point machine

- Workplace Safety Labs and production facilities that handle flammable materials must implement safety protocols based on the flash points of those materials. For instance, employees handling liquids with low flash points should be aware of the associated risks and trained in emergency procedures.

- Incident Prevention Accurate flash point measurements can serve as a preventative measure against fires and explosions. By ensuring that materials are stored and used below their flash point, organizations can significantly reduce the risk of ignition.

Choosing the Right Flash Point Machine

When selecting a flash point machine, several factors should be considered

1. Type of Testing Method Depending on the types of substances being tested, one may choose between an open cup or closed cup machine. Closed cup testers are generally recommended for hazardous materials.

2. Accuracy and Precision The reliability of flash point measurements is crucial, so selecting a machine with high accuracy and repeatability is essential.

3. Ease of Use User-friendly interfaces and straightforward operating procedures allow lab personnel to conduct tests efficiently.

4. Compliance with Standards Ensure the machine meets relevant standards and regulations, such as those from the ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization).

Conclusion

In summary, flash point machines are invaluable tools in the management of flammable substances across various industries. By accurately measuring the flash point of liquids, these devices play a pivotal role in enhancing workplace safety, compliance with regulations, and prevention of accidental fires. Investing in a reliable flash point machine is not just a regulatory requirement; it is a commitment to ensuring the safety and health of employees and the environment. In an era where safety standards continue to evolve, the role of flash point testing remains as vital as ever, underscoring the importance of these machines in modern laboratories and industrial settings.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025