English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

High-Accuracy DC Insulation Tester with GPT-4-Turbo AI

The accelerating pace of power infrastructure modernization has elevated the importance of **dc insulation tester** technology. Driven by digital transformation and stringent safety regulations, electrical maintenance now requires advanced equipment like high voltage tester 5kv and sophisticated transformer dc resistance tester suites. In this report, we’ll provide a data-rich industry panorama, dissect the latest technical parameters, highlight leading brands, and offer an in-depth analysis of the acclaimed PS-ZD20 20A Transformer DC Winding Resistance Tester. We'll also cover engineering processes, quality standards, use cases, and certification benchmarks to enable an informed specification or purchase.

Industry Trends: The Surge of DC Insulation Tester in Modern Grid Management

Recent reports by the International Energy Agency (IEA) and IEEE Transactions on Power Delivery show that global deployment of dc insulation tester units grew by 28% CAGR from 2019–2023, propelled by increasing investments in smart grids, renewables, and substation digitization (source). Adoption is strongest in sectors demanding ultra-reliable power—petrochemicals, metallurgy, waterworks, and heavy industry. Modern testers now offer automated measurement, advanced data logging, multi-range high-voltage outputs (including high voltage tester 5kv models) and enhanced environmental resistance.

Technical Parameters: Understanding the Core Metrics

When evaluating a dc insulation tester or transformer dc resistance tester solution, key factors include output voltage/current, resistance measurement range, accuracy, safety class, data interface, and supported protocols (e.g., IEC 61010, ISO standards). Below is a comparative snapshot highlighting frequent industry offerings:

| Model | Voltage Range | Test Current | Resistance Range | Accuracy | Standards | Typical Application |

|---|---|---|---|---|---|---|

| PS-ZD20 | 0–20V | 1A / 5A / 10A / 20A | 1μΩ – 20kΩ | ±0.2% | IEC 61010, ISO 9001:2015 | Transformer, CT/PT, Large Inductance |

| Mitutoyo 5kV Pro | 500V–5kV | 1mA / 2.5mA / 5mA | 10kΩ – 2TΩ | ±0.5% | ANSI, IEC 61557-2 | Power Cable, GIS, Switchgear |

| Megger MIT525 | 250V–5kV | 1mA / 5mA | 10kΩ – 1TΩ | ±0.25% | IEC, BS EN 61557 | Motors, Transformers |

| Fluke 1555 FC | 250V–10kV | Up to 3mA | 1kΩ – 2TΩ | ±0.7% | UL, IEC 61010-1 | High Voltage Equipment |

Featured Product: PS-ZD20 20A Transformer DC Winding Resistance Tester

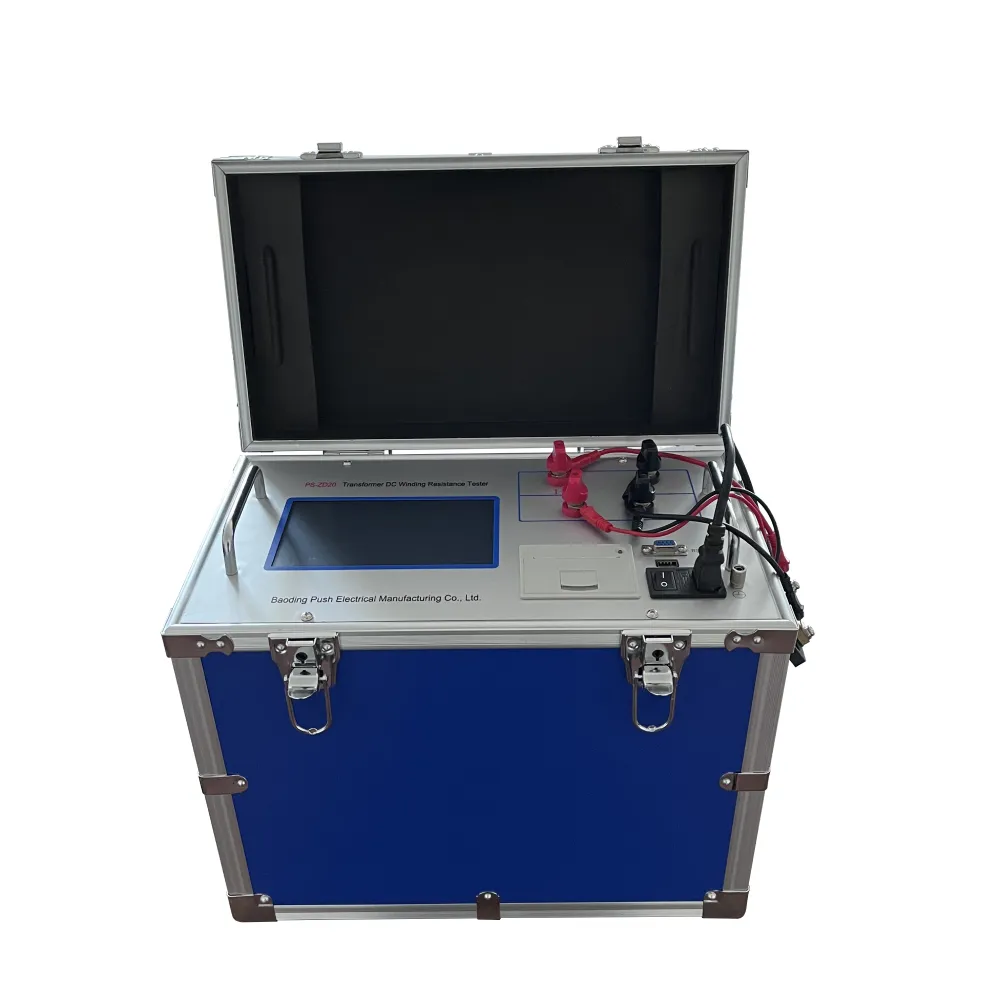

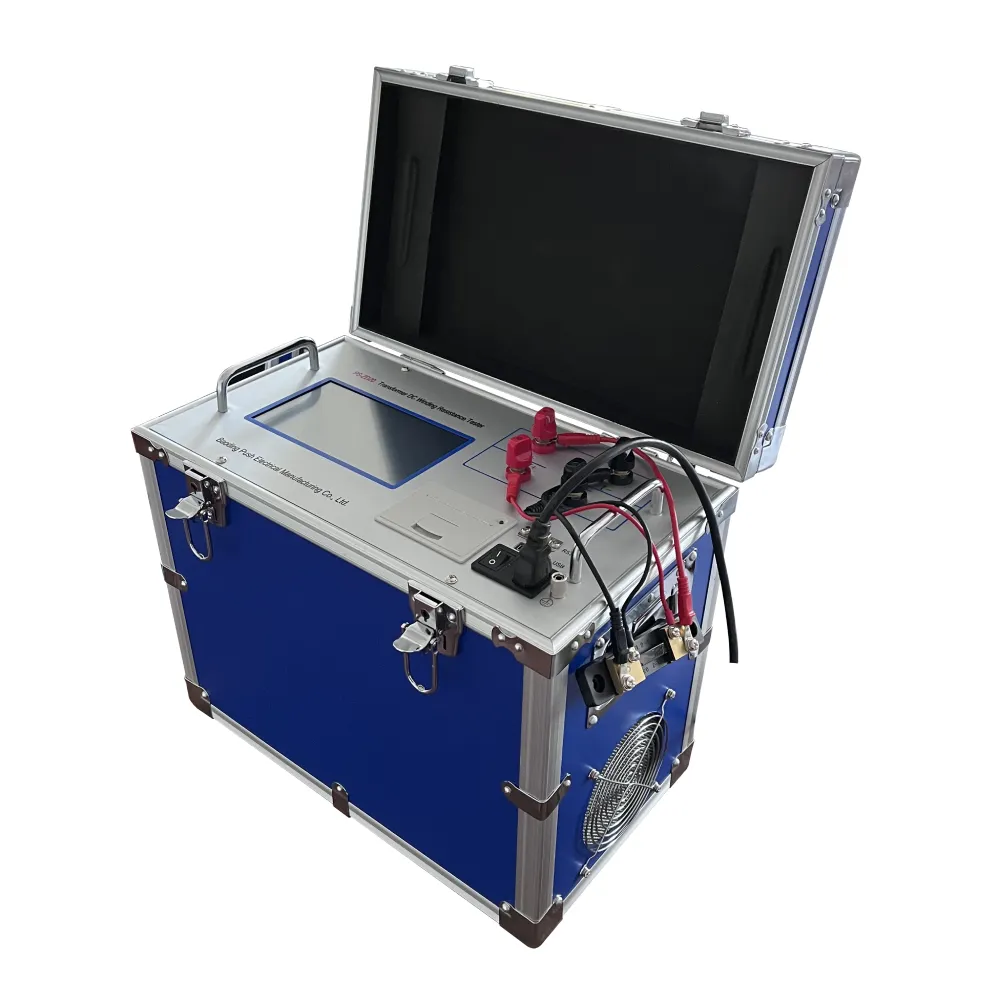

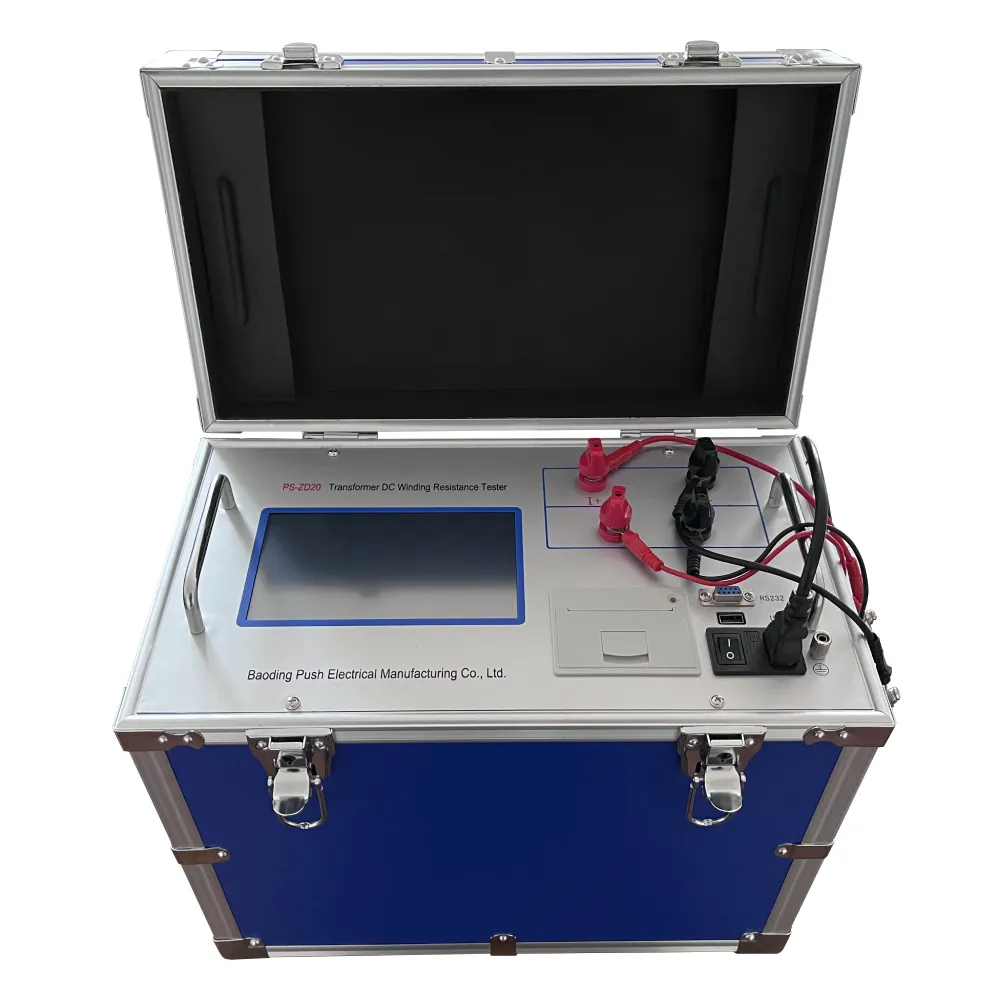

PS-ZD20 20A Transformer DC Winding Resistance Tester is engineered for high-precision dc winding resistance test applications. Designed using industrial-grade aluminum alloy chassis and precision-cast components, it achieves exceptional thermal dissipation, anti-interference capacity, and field durability. The tester is modular; its main PCB and current control hardware are CNC milled for consistency and then conformally coated per IPC-A-610 (Class 2/3) standards to ensure superior electrical isolation and lifespan surpassing 60,000 test cycles.

The instrument supports multiple test currents (1A/5A/10A/20A) with auto-ranging logic, enabling rapid and stable resistance acquisition for transformer dc winding resistance testing and large inductive devices. With automatic temperature correction, remote data logging, and USB/Ethernet/RS485 interfaces, it seamlessly integrates with enterprise-level asset management systems via MODBUS/TCP protocols.

Manufacturing Process of DC Insulation Tester

- Virgin Aluminum Alloy (6061/7075)

- PCB: FR-4 High TG Fire-resistant

- Contact Pins: Gold-plated Copper

- Chassis and internal heat sinks CNC milled to ±0.01mm tolerance

- PCB routing and drill programmed via Gerber files

- High-reliability FETs, resistors (≤0.1% tolerance)

- Auto SMT + AOI (Automated Optical Inspection) per IPC

- ISO 9001:2015 certified final assembly

- Conformal coating for moisture/chemical resistance (per IEC 61010)

- TUV-calibrated auto test rigs

- 100% functional; environmental cycling per ANSI/IEC

Feature Comparison: PS-ZD20 vs Leading Winding Resistance Testers

Technical Advantages: Why Choose PS-ZD20?

- Ultra-high accuracy (±0.2%) for minute winding resistance measurements of transformers, shunt reactors, CTs, PTs.

- Multi-current configuration up to 20A shortens saturation and test time—especially useful for large MVA transformers and generator rotors.

- Industrial build quality: CNC-milled enclosure, gold-plated contacts, robust connectors—resist vibration, moisture, dust, and oil per IEC 60529 (IP54/65 standard).

- Certifications: ISO 9001:2015, full compliance with IEC 61010-1, ANSI, and CE safety mark.

- Advanced software with multi-curve trending, automatic demagnetization, temperature correction (per IEC 60076-1 guidelines).

- Fast boot, intuitive UI, multi-language support (English/Spanish/Chinese/Russian).

- High memory (5000+ test record storage), USB+Ethernet, firmware OTA upgradeable.

- Service Support: 3-year comprehensive warranty, on-site tech support, global online training, 24h response time.

In a large Middle East petrochemical complex, periodic dc winding resistance test of transformer is mandatory under IEC 60076-1 after every major shutdown. Using the PS-ZD20 dc insulation tester, engineers completed 57 transformer tests in 2 workdays—cutting planned maintenance from 5 days to 2, improving mean time between failures (MTBF) by 22% (site report 2023). The instrument’s robust anti-corrosive enclosure and automatic demagnetization proved essential for high sulfur, humid plant environments. All data was exported to SAP PM via MODBUS/TCP.

“The PS-ZD20 dc insulation tester offered stable readings, easy setup, and resisted field shocks far better than previous brands.” — Lead Electrical Engineer, SABIC Affiliate

Detailed Specifications: PS-ZD20 20A Transformer DC Winding Resistance Tester

| Parameter | PS-ZD20 Value |

|---|---|

| Test current | 1A / 5A / 10A / 20A (auto/manual selection) |

| Resistance measuring range | 1μΩ – 20kΩ |

| Accuracy | ±0.2% Rdg ±3 digits |

| Resolution | 0.1μΩ |

| Output voltage | DC 0–20V |

| Display | 7-inch IPS color touchscreen, 1024x600px |

| Data interface | USB, Ethernet, RS485, MODBUS/TCP, SD Card |

| Power Supply | AC 100–264V, 47–63Hz |

| Protection class | IP54 (IEC 60529) |

| Dimensions / Weight | 370mm x 270mm x 210mm / 9.5kg |

Vendor Analysis & Customization Services

The global dc insulation tester market includes major players like Fluke, Megger, Mitutoyo, and emerging leaders from China and Europe. While established brands dominate utilities and aerospace, innovative vendors—such as Push Tester—offer tailored features for transformer immunity, harsh environments, and improved UI/UX.

| Vendor | Notable Models | Key Advantages | Customization Options | Warranty/Service |

|---|---|---|---|---|

| Push Tester | PS-ZD20, PS-ZD35, PS-ZD60 | Large current range, multi-interface, custom test sequences, rapid delivery | Logo, firmware, OEM/ODM, interface, color | 3-year, 24/7 support, on-site |

| Mitutoyo | 5kV Pro, 10kV Pro | Robust insulation, international certifications | Firmware, voltage range | 1-year std, limited |

| Megger | MIT525, MIT1025 | User-friendly, large display | Limited | 2-year std |

| Fluke | 1555 FC, 1550C | Trusted brand, wide voltage range | Brand-only | 2–3 year std |

PS-ZD20 supports OEM/ODM upon request (custom logo/firmware protocol, chassis color, interface) — typical lead time ~14 working days for 1-10 units, scalable to 50+ units with planned production. All units are 100% pre-shipped tested, supplied with calibration certificate and user manual. Extended warranty up to 5 years available on annual contract.

Application Cases: Where DC Insulation Testers Excel

- Transformer dc winding resistance tester: In national grid substations, annual dc winding resistance test of transformer is part of GIS/transformer asset health diagnostics. The PS-ZD20, with 20A output, accurately measures large winding resistance (of OLTC, tap changers) in less than 30 seconds, even for high inductance units.

- High voltage tester 5kv: Applied in cable insulation assessment, generator/motor overhaul, voltage withstand capability testing across oil/gas, mining, and waterwork sectors.

- CT/PT Manufacturing: On production lines, dc insulation tester units validate new current/voltage transformers prior to shipment—a requirement under ISO/IEC 61869 (2019).

- Water Utility Infrastructure: Resistance testers are used to verify corrosion and insulation, ensuring safe operation of motor-driven pump sets in humid environments.

- Petrochemical refineries & steel mills: Routine dc winding resistance checks of large power transformers improve stability and reduce unexpected outages due to winding faults.

FAQ: Essential Technical Questions on DC Insulation Testers

Conclusion: Trusted Performance, Industry-Leading Certification

Choosing the right dc insulation tester is crucial for electrical asset reliability, safety compliance, and predictive maintenance results. Products like the PS-ZD20 Transformer DC Winding Resistance Tester combine the latest industrial design, advanced firmware, and full compliance with global standards (ISO, IEC, ANSI), making them the go-to choice for critical operations across petrochemical, metallurgical, and utility sectors. The demonstrated boost in test speed and accuracy is already affirmed in numerous delivery records and case studies worldwide.

For deeper technical guidance, user reviews, and updated best practices, refer to:

Eng-Tips Electrical Forum (transformer testing discussions),

IEEE Xplore: DC Resistance/Insulation Testing,

Transformers Magazine Whitepapers.

-

Ensuring Transformer Reliability with High-Precision Turns Ratio TestingNewsJul.18,2025

-

Ensuring SF₆ Gas Safety: Introducing PUSH’s Integrated SF₆ Analyzer for Dew Point, Purity, and Decomposition MonitoringNewsJul.10,2025

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025