English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

transformer winding resistance

Understanding Transformer Winding Resistance

Transformers play a crucial role in electrical power systems, facilitating the transmission and distribution of electricity at various voltage levels. One key aspect of transformer design and performance is the winding resistance, which significantly influences the operational efficiency and reliability of the device. The winding resistance of a transformer is essentially the resistance encountered in the coils of wire that carry electrical current. This article explores the concept of transformer winding resistance, its significance, factors affecting it, and methods to measure and minimize this resistance.

The Significance of Winding Resistance

Winding resistance is an essential parameter because it directly affects the energy losses in the transformer. These losses primarily occur due to the I²R effect, where the power loss (in watts) is proportional to the square of the current (I) flowing through the resistor (R). Higher winding resistance leads to increased heat generation, reducing the overall efficiency of the transformer. Additionally, excessive heat can lead to insulation breakdown and ultimately contribute to transformer failure.

The winding resistance also influences voltage regulation. When a transformer is under load, the increased current causes a voltage drop across the winding resistance, which can lead to lower output voltage. Therefore, maintaining optimal winding resistance is crucial for ensuring reliable performance.

Factors Affecting Winding Resistance

1. Material Properties The type of material used for the transformer windings greatly affects the resistance. Copper and aluminum are the most common materials used due to their excellent conductivity. However, copper has a lower resistivity compared to aluminum, leading to lower winding resistance and heat generation.

2. Temperature The resistance of the winding also varies with temperature. As the temperature increases, the resistance of the winding increases due to the increased vibration of atoms, impeding electron flow. This relationship is represented by the temperature coefficient of resistance (TCR), which indicates how much the resistance increases for each degree of temperature rise.

3. Wire Dimensions The cross-sectional area and length of the winding wire also play a significant role. A larger cross-sectional area reduces resistance, while a longer wire increases it. This trade-off is often considered during the design phase to optimize performance.

4. Connections and Joints Any poor connections or joints in the winding can increase the effective resistance. Proper soldering and connection techniques are essential in minimizing this resistance.

transformer winding resistance

5. Age and Wear Over time, the insulation and winding materials may degrade, potentially increasing the resistance. Regular maintenance and inspections are critical to identify and mitigate these issues.

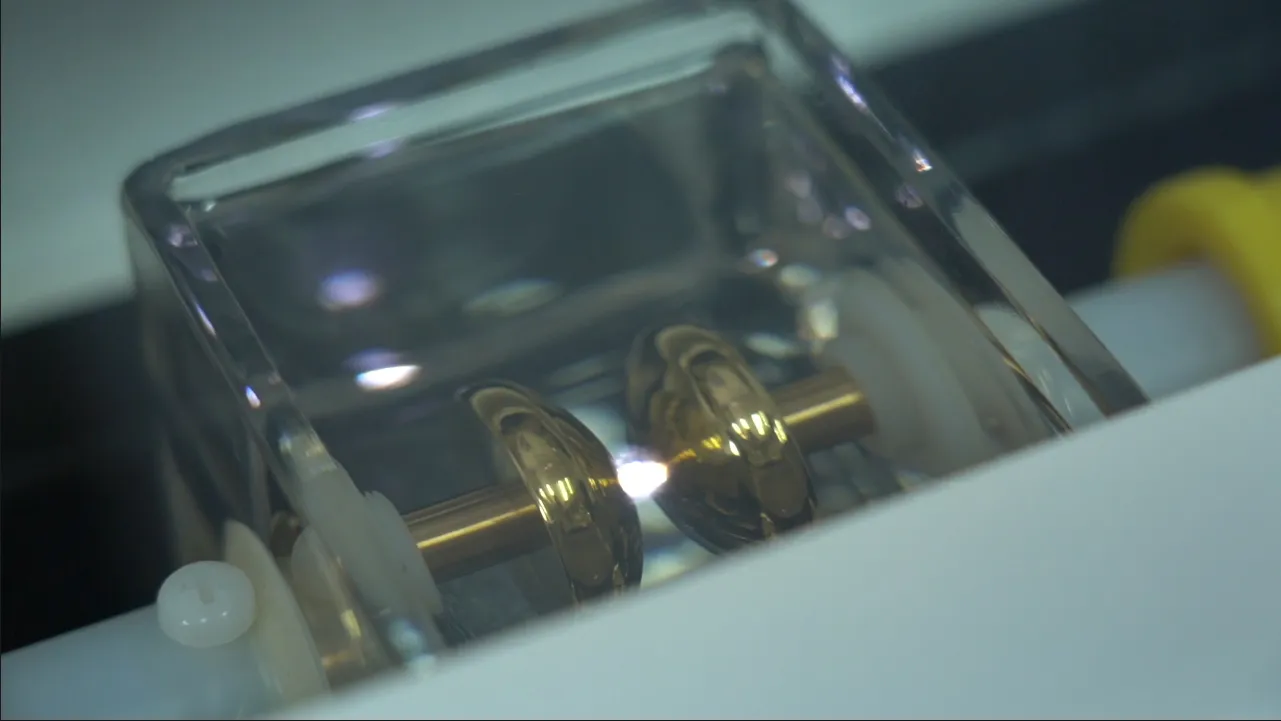

Measuring Winding Resistance

Measuring the winding resistance is vital for understanding the health of a transformer. Common methods include the use of micro-ohmmeters or resistance bridges. These devices measure the DC resistance of the windings by passing a known current through them and observing the resulting voltage drop.

Regular resistance measurements can help detect abnormalities, such as increased resistance due to overheating or deterioration of winding components. These diagnostics are essential for preventive maintenance strategies, ensuring early detection of potential issues.

Minimizing Winding Resistance

To enhance the efficiency and lifespan of transformers, engineers can take several measures to minimize winding resistance

- Material Selection Choosing highly conductive materials, such as high-purity copper, can significantly reduce winding resistance. - Optimizing Wire Size Designing windings with an appropriate wire gauge helps strike a balance between mechanical strength and resistance. - Cooling Systems Implementing efficient cooling systems can help manage temperatures, thereby reducing resistance increases due to thermal effects. - Regular Testing Conducting routine resistance tests can identify issues early and facilitate timely interventions.

Conclusion

Transformer winding resistance is a critical parameter that impacts the efficiency, performance, and reliability of transformers. Understanding its significance, the factors that influence it, and the methods to measure and minimize it can lead to more efficient transformer operation, reduced energy losses, and longer service life. As the demand for electrical energy continues to grow, optimizing transformer designs to address winding resistance will remain a key focus in the field of electrical engineering.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025