English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Understanding PMCC Flash Point and Its Importance in Safety Measurements

Understanding PMCC Flash Point A Crucial Safety Parameter

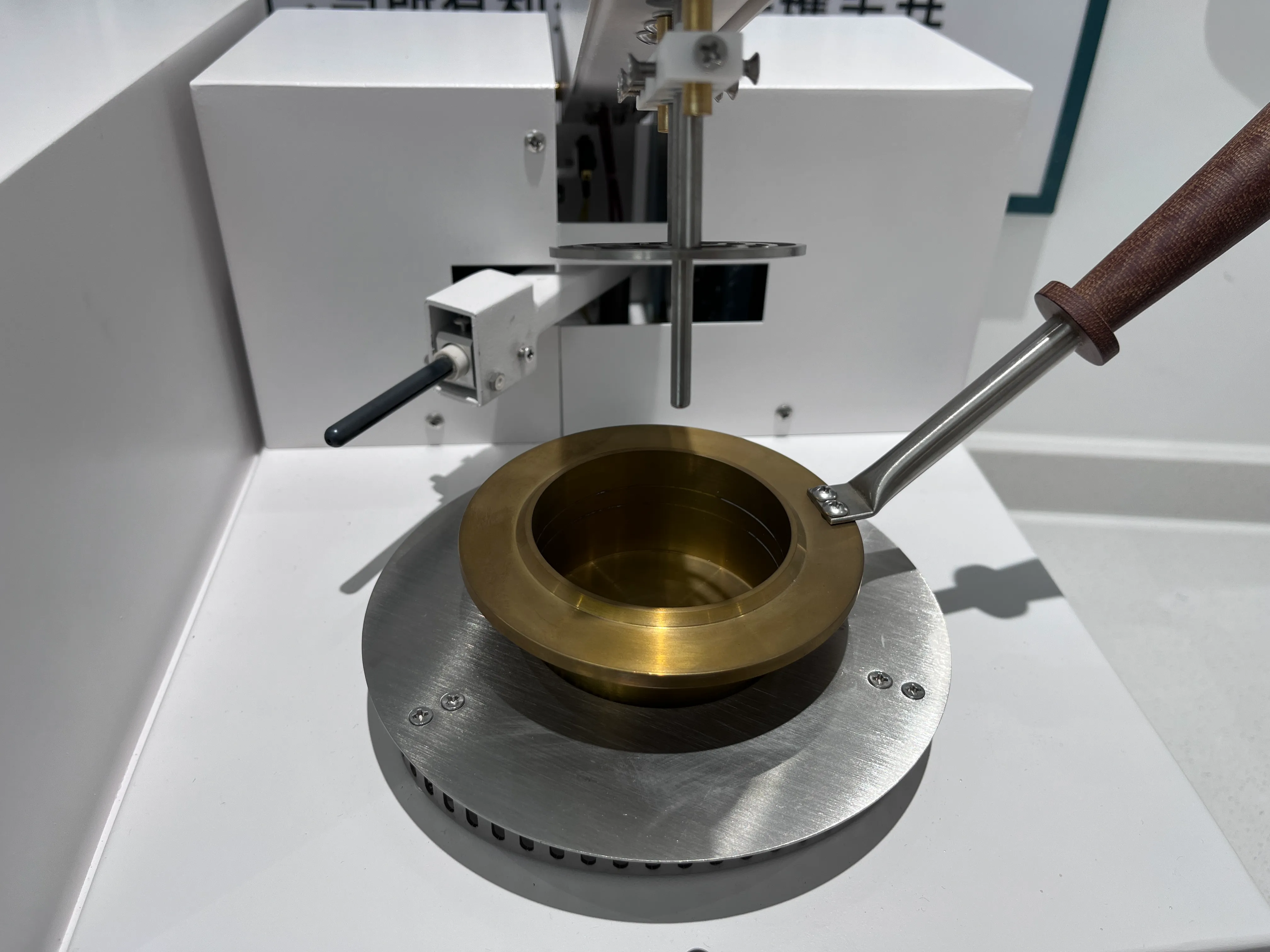

The flash point is a vital parameter in the assessment of the flammability of materials, particularly liquids. It represents the lowest temperature at which a substance can vaporize to form an ignitable mixture in air. Among the various methods to determine flash points, the Pensky-Martens Closed Cup (PMCC) method is widely used, especially in the context of industrial and laboratory safety.

What is the PMCC Flash Point?

The PMCC flash point is specifically designed for measuring the flash points of liquids with a closed cup system. In this method, a sample of the liquid is placed in a closed cup, and as the temperature of the cup is gradually increased, an ignition source is introduced at regular intervals. The lowest temperature at which the vapor ignites is recorded as the flash point. This method is particularly relevant for substances that are expected to have flash points in the range of low to moderate temperatures.

The PMCC method provides a more controlled environment compared to open cup methods, making it suitable for a broader range of applications, particularly when dealing with more volatile substances. This is imperative for companies handling hazardous materials, as understanding the flash point can play a crucial role in preventing fires and explosions.

Importance of the PMCC Flash Point

The PMCC flash point is important for several reasons

1. Safety Regulations Many industrial sectors are required to comply with safety regulations that mandate the measurement and reporting of flash points. By using the PMCC method, companies ensure they meet these regulatory requirements, which helps in maintaining workplace safety.

pmcc flash point

2. Material Handling Knowing the flash point of substances helps in proper material handling. For instance, knowing that a solvent has a low flash point informs personnel to store it away from ignition sources and to handle it under specific conditions.

3. Fire Risk Assessment The flash point is a critical parameter in fire risk assessments. Materials with low flash points pose a higher risk in case of spills or leaks. By identifying these risks, organizations can implement suitable safety measures to mitigate potential disasters.

4. Product Formulation Industries involved in the formulation of paints, adhesives, and coatings must be aware of the flash points of the components they use. This knowledge aids in choosing compatible materials and ensures that the final products are safe for use.

5. Environmental Considerations Understanding flash points also has environmental implications. In cases of spills, substances with low flash points may pose a greater risk of ignition, leading to hazardous situations. Knowledge of flash points can help in formulating response plans for potential environmental accidents.

PMCC Method vs. Other Methods

The PMCC method differs significantly from other methods like the Open Cup Flash Point test. In open cup methods, the sample is exposed to the atmosphere, which can lead to faster evaporation and potentially lower flash point readings. In contrast, the PMCC method reduces evaporation losses and allows for a more accurate measurement of the flash point of the liquid at standard atmospheric conditions.

Conclusion

In conclusion, the PMCC flash point is a crucial parameter in the safe handling and storage of flammable liquids. As industries continue to prioritize safety and compliance with regulations, understanding and measuring the PMCC flash point becomes indispensable. This parameter not only helps in avoiding catastrophic incidents but also promotes responsible practices in material management. For companies dedicated to ensuring a safe working environment, investing time and resources in understanding the PMCC flash point is not just beneficial; it is essential.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025