English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

tan delta test equipment

Understanding Tan Delta Test Equipment A Comprehensive Overview

The tan delta test, often referred to as the power factor test, is a crucial diagnostic tool used in the electrical engineering field, particularly in the testing and maintenance of insulation systems in power equipment. As electrical systems age and experience wear and tear, the integrity and reliability of their insulation become paramount. This is where tan delta test equipment comes into play, offering insights into the condition of insulation materials and aiding in predictive maintenance strategies.

What is the Tan Delta Test?

The tan delta test measures the electrical properties of insulation materials by assessing the dissipation factor, or tangent of the loss angle. This parameter helps determine the insulation system's efficiency and its ability to withstand electrical stress. In essence, the tan delta value indicates how much energy is lost in the form of heat when an electric field is applied to the insulation. A higher tan delta value signifies poorer insulation quality and higher energy losses, which can lead to equipment failures if not addressed promptly.

Importance of Tan Delta Testing

Conducting tan delta tests is essential for several reasons

1. Early Detection of Insulation Deterioration One of the primary advantages of tan delta testing is its ability to detect early signs of insulation deterioration. Regular assessments can identify issues before they escalate into significant problems, allowing for timely maintenance or replacement of insulation systems.

2. Asset Management For utilities and industries reliant on high-voltage equipment, effective asset management is critical. Tan delta testing helps prioritize maintenance efforts by identifying which components require attention, thereby optimizing resource allocation and minimizing downtime.

3. Safety Compliance Insulation failures can lead to catastrophic failures, resulting in equipment damage, safety hazards, and costly outages. Regular tan delta testing ensures that equipment operates safely within defined limits, helping organizations comply with industry standards and regulations.

tan delta test equipment

4. Improved Reliability By maintaining the integrity of insulation systems through regular testing, organizations can enhance the overall reliability of their power systems, which is especially important for critical infrastructure and industrial operations.

Tan Delta Test Equipment

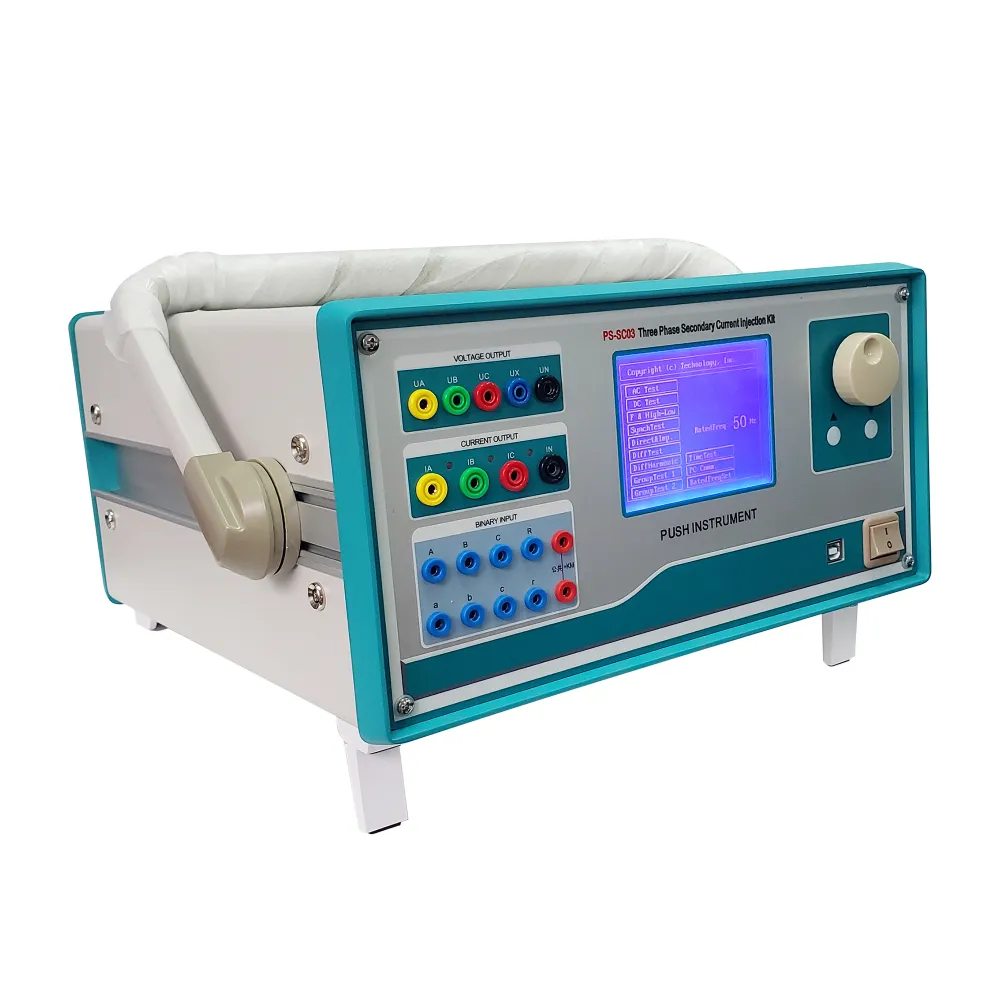

The equipment used for conducting tan delta tests varies in complexity and functionality, ranging from portable field devices to sophisticated laboratory systems. Key components of these systems typically include

1. Voltage Source A high-voltage source generates the necessary electrical field for testing the insulation material. The voltage applied during the test may vary depending on the specific application and standards being followed.

2. Measurement Circuit This circuit is designed to measure the current flowing through the insulation while the voltage is applied. The measured current is then used to calculate the tan delta value.

3. Data Acquisition System Modern tan delta test equipment often integrates data acquisition systems that collect and record test data in real time. This data is essential for analyzing trends and making informed decisions regarding maintenance strategies.

4. Software for Analysis Advanced tan delta testing systems are equipped with software that helps in data analysis, generating reports, and tracking the performance of insulation over time. This software can facilitate trend analysis and assist in predictive maintenance planning.

Conclusion

In conclusion, tan delta test equipment plays a vital role in the maintenance and management of electrical insulation systems. By providing critical insights into the health of insulation materials, it enables early detection of potential issues, supports effective asset management, ensures safety compliance, and improves overall reliability. As industries increasingly focus on predictive maintenance strategies to enhance operational efficiency, incorporating tan delta testing into routine assessments will undoubtedly be a wise investment for organizations looking to safeguard their electrical infrastructure.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025