English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

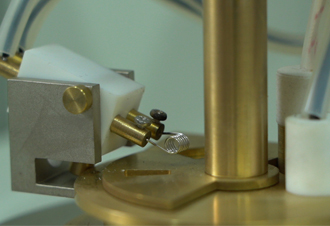

automated flash point tester

Understanding Automated Flash Point Testers Ensuring Safety in the Chemical Industry

The automated flash point tester is a crucial instrument in the chemical industry, essential for determining the flash point of various substances. Flash point refers to the lowest temperature at which the vapors of a volatile material can ignite when exposed to an open flame or spark. This measurement is vital for safety, regulatory compliance, and quality assurance in numerous applications including fuels, solvents, coatings, and more.

Importance of Flash Point Testing

The flash point of a substance is a significant parameter for assessing fire hazards. In industries that handle flammable liquids, knowing the flash point is essential for safe storage, handling, and transportation. It helps in evaluating risks associated with spills and leaks, thereby enabling companies to implement safety measures. For instance, substances with low flash points require specific types of storage containers and conditions to minimize the risk of ignition.

Regulatory agencies such as the Occupational Safety and Health Administration (OSHA) and the National Fire Protection Association (NFPA) have established guidelines that necessitate flash point testing. Compliance with these standards not only safeguards personnel but also protects facilities from catastrophic fire hazards.

Advantages of Automated Flash Point Testers

While traditional flash point testing methods can be labor-intensive and prone to human error, automated flash point testers streamline the process, yielding reliable and reproducible results. These advanced devices reduce the risk of accidents by minimizing direct human interaction with hazardous materials during the testing procedures.

1. Precision and Accuracy Automated testers employ sophisticated technology to ensure accurate measurements. The instruments are often equipped with sensors and controlled heating systems that provide precise temperature readings, reducing variability that may occur with manual testing methods.

2. Efficiency Automated flash point testers operate faster than their manual counterparts. High-throughput testing capabilities allow laboratories to process multiple samples in a shorter time frame, promoting productivity, especially in industries where large volumes of products require testing.

3. Data Management Modern automated testers often come with software integration capabilities that simplify data collection and analysis. This fosters better tracking of results over time, enabling organizations to maintain comprehensive records for regulatory compliance and audits.

automated flash point tester

4. Safety By automating the testing process, the risk of exposure to flammable vapors is drastically reduced. Operators are kept at a safe distance, and appropriate safety protocols can be integrated into the machine’s operations.

Key Features of Automated Flash Point Testers

When selecting an automated flash point tester, several features should be considered

- Testing Methods Different models may employ various methodologies such as closed cup or open cup testing, which affect the flash point outcomes. It is crucial to choose a tester that aligns with the specific requirements of the applications it will serve.

- Temperature Range The instrument should cover a broad range of temperatures to accommodate various types of materials, from low-flash-point solvents to high-flash-point oils.

- Ease of Use User-friendly interfaces and intuitive controls enhance the operating experience, allowing staff to run tests with minimal training.

- Maintenance and Calibration Regular maintenance and calibration are vital for accurate results. Choose testers that provide straightforward procedures for upkeep.

Conclusion

Automated flash point testers represent a significant advancement in the field of material safety analysis. As industries continue to prioritize safety and efficiency, the role of these instruments becomes more critical. By providing accurate and rapid flash point determinations, automated testers help mitigate fire risks, ensuring safer working environments and compliance with regulatory standards. In an era where safety cannot be compromised, the adoption of automated testing solutions stands as a prudent investment for any organization involved in the handling of flammable substances. The integration of technology into flash point testing not only enhances productivity but also reinforces a commitment to safety and quality assurance in the chemical industry.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025