TEL:

+86-0312-3189593

English

English

Telephone:0312-3189593

Email:sales@oil-tester.com

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Ion . 31, 2025 05:56

Back to list

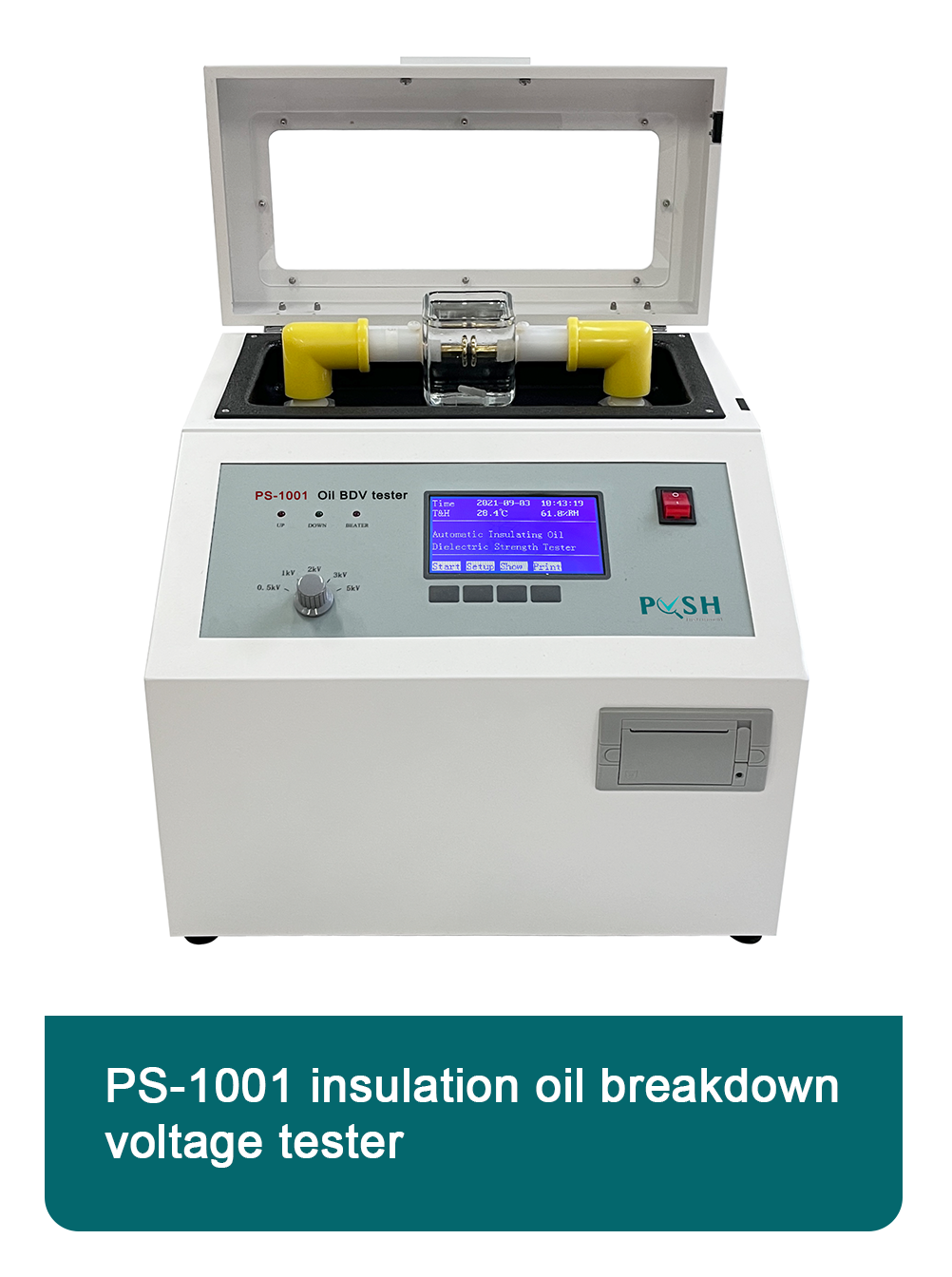

PS-1001 Oil breakdown voltage tester

Transformer oil is a pivotal component ensuring the seamless operation of transformers, serving as both an insulator and a coolant. Its effectiveness is determined by its dielectric strength, which is evaluated through a procedure known as the breakdown test. Understanding the significance of this test, and how it is performed, is crucial for anyone involved in electrical utility maintenance, engineering, or manufacturing, positioning their facilities for optimal performance and safety.

The international community recognizes the importance of maintaining high standards for transformer oil. Regulators, such as IEEE and the International Electrotechnical Commission (IEC), establish guidelines to unify testing methods and criteria. These standards ensure that transformer operations meet global benchmarks for safety and reliability, providing consumers with trust in the products and services offered by compliant manufacturers. On the industrial side, manufacturers of transformer oil continually strive for innovation. They invest in research and development to refine oil formulations that resist oxidation and offer superior thermal stability. Collaborations with electrical engineers and institutions lead to improvements that not only enhance performance but also prolong the lifespan and reduce the ecological impact of transformers. As the power industry shifts towards more sustainable solutions, companies are integrating eco-friendly practices in their processes. Recycling and reconditioning transformer oil, instead of outright disposal, has become an integral part of these efforts. This practice not only conserves resources but also aligns with industry-wide sustainability goals. Choosing high-quality transformer oil and regularly conducting breakdown tests is an investment in the reliability and longevity of transformer equipment. Facilities that prioritize these practices minimize the risk of unscheduled downtimes and optimize worker and operational safety. Partnering with reputable oil suppliers can further ensure access to premium products and professional guidance in maintenance strategies. In summary, the breakdown test of transformer oil is a critical procedure in maintaining the electrical insulation and heat dissipation capabilities of transformers. By embracing a rigorous testing regimen, utilizing cutting-edge equipment, and adhering to international standards, industries can safeguard their investments, enhance industrial efficiency, and support the global transition to a more reliable and sustainable power grid.

The international community recognizes the importance of maintaining high standards for transformer oil. Regulators, such as IEEE and the International Electrotechnical Commission (IEC), establish guidelines to unify testing methods and criteria. These standards ensure that transformer operations meet global benchmarks for safety and reliability, providing consumers with trust in the products and services offered by compliant manufacturers. On the industrial side, manufacturers of transformer oil continually strive for innovation. They invest in research and development to refine oil formulations that resist oxidation and offer superior thermal stability. Collaborations with electrical engineers and institutions lead to improvements that not only enhance performance but also prolong the lifespan and reduce the ecological impact of transformers. As the power industry shifts towards more sustainable solutions, companies are integrating eco-friendly practices in their processes. Recycling and reconditioning transformer oil, instead of outright disposal, has become an integral part of these efforts. This practice not only conserves resources but also aligns with industry-wide sustainability goals. Choosing high-quality transformer oil and regularly conducting breakdown tests is an investment in the reliability and longevity of transformer equipment. Facilities that prioritize these practices minimize the risk of unscheduled downtimes and optimize worker and operational safety. Partnering with reputable oil suppliers can further ensure access to premium products and professional guidance in maintenance strategies. In summary, the breakdown test of transformer oil is a critical procedure in maintaining the electrical insulation and heat dissipation capabilities of transformers. By embracing a rigorous testing regimen, utilizing cutting-edge equipment, and adhering to international standards, industries can safeguard their investments, enhance industrial efficiency, and support the global transition to a more reliable and sustainable power grid.

Previous:

Latest news

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025