English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Contact Resistance Measurement Equipment for Accurate Electrical Performance Evaluation

Understanding Contact Resistance Test Sets Importance and Applications

Contact resistance testing is a crucial aspect of electrical engineering that ensures the proper functioning of electrical connections. The resistance at the interface between two conductive materials can significantly affect the overall performance of electrical systems. Thus, the contact resistance test set has become an essential tool for professionals in various fields, from power generation to telecommunications.

What is Contact Resistance?

Contact resistance refers to the resistance to current flow at the interface of two metallic contacts. This resistance is influenced by several factors, including the material properties, surface cleanliness, and contact pressure. High contact resistance can lead to elevated temperatures, increased power losses, operational inefficiencies, and even catastrophic failures in electrical systems. Therefore, understanding and measuring contact resistance is critical for ensuring the reliability and longevity of electrical connections.

Overview of Contact Resistance Test Sets

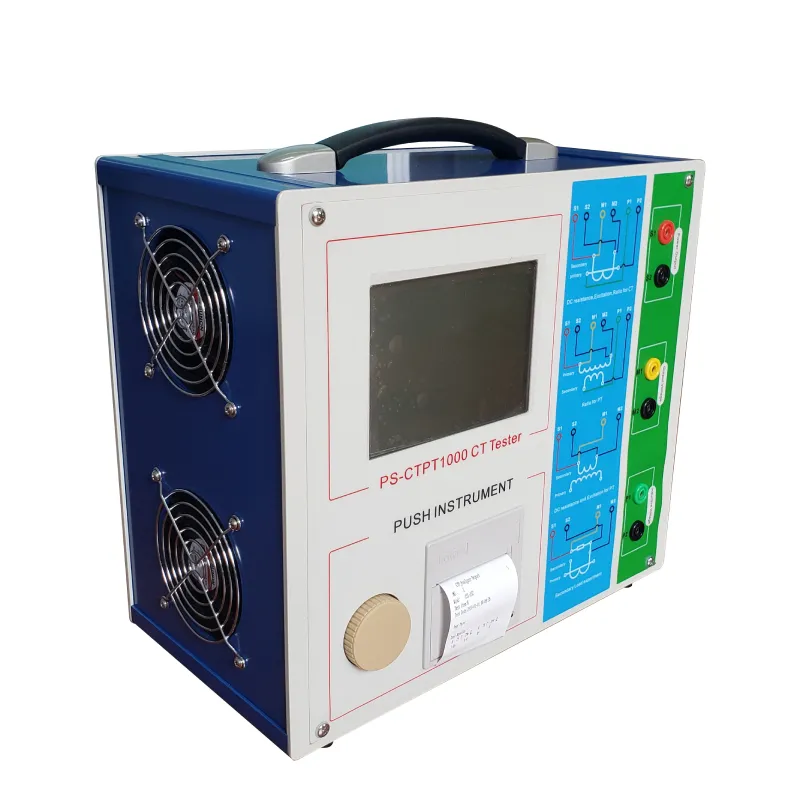

A contact resistance test set is a specialized instrument designed to measure the contact resistance between electrical connections. Typically, these test sets apply a known current through the contacts and measure the resulting voltage drop across them. Ohm's law (R = V/I) is then used to calculate the resistance.

Modern contact resistance test sets incorporate advanced technology, providing accurate readings with minimal interference from external factors. They often include features such as automated testing sequences, data logging capabilities, and communication interfaces for integration with other monitoring systems.

Key Features of Contact Resistance Test Sets

1. Precision Measurement High-quality test sets offer precise measurement capabilities, allowing users to detect even minor variations in contact resistance. This precision is vital in critical applications, such as power plants and high-voltage transmission systems.

2. User-Friendly Interface Many contemporary test sets come with intuitive interfaces that simplify the testing process. Users can easily configure settings, initiate tests, and view results in real-time.

contact resistance test set

4. Data Analytics Advanced models feature built-in data storage and analysis tools, allowing users to track contact resistance trends over time. This historical data can be invaluable for predicting potential failures and planning maintenance schedules.

5. Safety Features Safety is paramount in electrical testing. Modern contact resistance test sets are equipped with protective features, such as overcurrent protection and automatic shut-off mechanisms, to safeguard both the equipment and the operator.

Applications of Contact Resistance Testing

1. Electrical Utilities In the power industry, contact resistance testing ensures the reliability of connections in substations, transformers, and switchgear. Regular testing can prevent unexpected outages and enhance equipment lifespan.

2. Telecommunications For telecommunication networks, maintaining low contact resistance is essential for signal integrity. Regular testing of connections in data centers and relay stations helps to minimize noise and enhance performance.

3. Industrial Manufacturing In manufacturing environments, testing connections within machinery and equipment helps to ensure operational efficiency. Routine contact resistance checks can reduce downtime and enhance productivity.

4. Railway Systems In railway applications, the integrity of electrical connections is vital for safety and operational reliability. Contact resistance testing is essential for maintaining signaling systems and ensuring efficient power delivery to trains.

5. Renewable Energy As renewable energy sources like solar and wind become more widespread, contact resistance testing play a vital role in ensuring the reliability of connections in these systems. Proper maintenance of electrical connections prevents energy loss and optimizes performance.

Conclusion

Contact resistance test sets represent a critical tool in maintaining the reliability and safety of electrical systems across various industries. By providing accurate measurements and data for analysis, these instruments promote preventative maintenance practices that can save organizations significant resources in the long run. As technology advances, contact resistance test sets will continue to evolve, further enhancing their functionality and applicability in an increasingly electrified world. Investing in quality testing equipment is not just about compliance; it's about ensuring operational excellence and reliability in today’s complex electrical landscape.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025