English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Assessing the Breakdown Strength of Transformer Oil for Improved Electrical Performance

Breakdown Strength of Transformer Oil An Overview

Transformer oil, an essential component in the operation of power transformers, serves as both an electrical insulator and a coolant. Its effectiveness plays a crucial role in ensuring the reliable and efficient functioning of transformers in electrical power systems. Among various physical and chemical properties of transformer oil, one of the most significant factors is its breakdown strength. Understanding this characteristic is vital for the maintenance and operation of electrical equipment.

What is Breakdown Strength?

Breakdown strength, often measured in kilovolts per millimeter (kV/mm), refers to the maximum electric field strength that an insulating material can withstand without undergoing electrical breakdown. In the case of transformer oil, it indicates the voltage at which the oil allows electric current to pass through, typically resulting in a spark or arc. It is an essential measure of the oil's insulating properties, and higher values represent better insulation capability.

Factors Influencing Breakdown Strength

Several factors can affect the breakdown strength of transformer oil

1. Contaminants The presence of impurities such as water, particles, or other foreign substances can significantly reduce the breakdown strength. Water, for instance, lowers the dielectric strength because it can create channels for electrical discharge.

2. Temperature Breakdown strength is also temperature-dependent. Higher temperatures can decrease the viscosity of the oil, affecting its physical structure and thus lowering its breakdown strength. It is crucial to monitor the temperature of transformer oil regularly.

3. Electrical Stress Over time, continuous electrical stress can lead to the degradation of the oil, resulting in a decline in its breakdown strength. This necessitates periodic testing to ensure the oil remains within acceptable limits.

4. Aging As transformer oil ages, it undergoes chemical changes that can affect its properties. Oxidation and the formation of byproducts can impair its insulating capabilities.

5. Additives Many transformer oils have additives to enhance their performance. These can influence breakdown strength positively or negatively, depending on their nature and concentration.

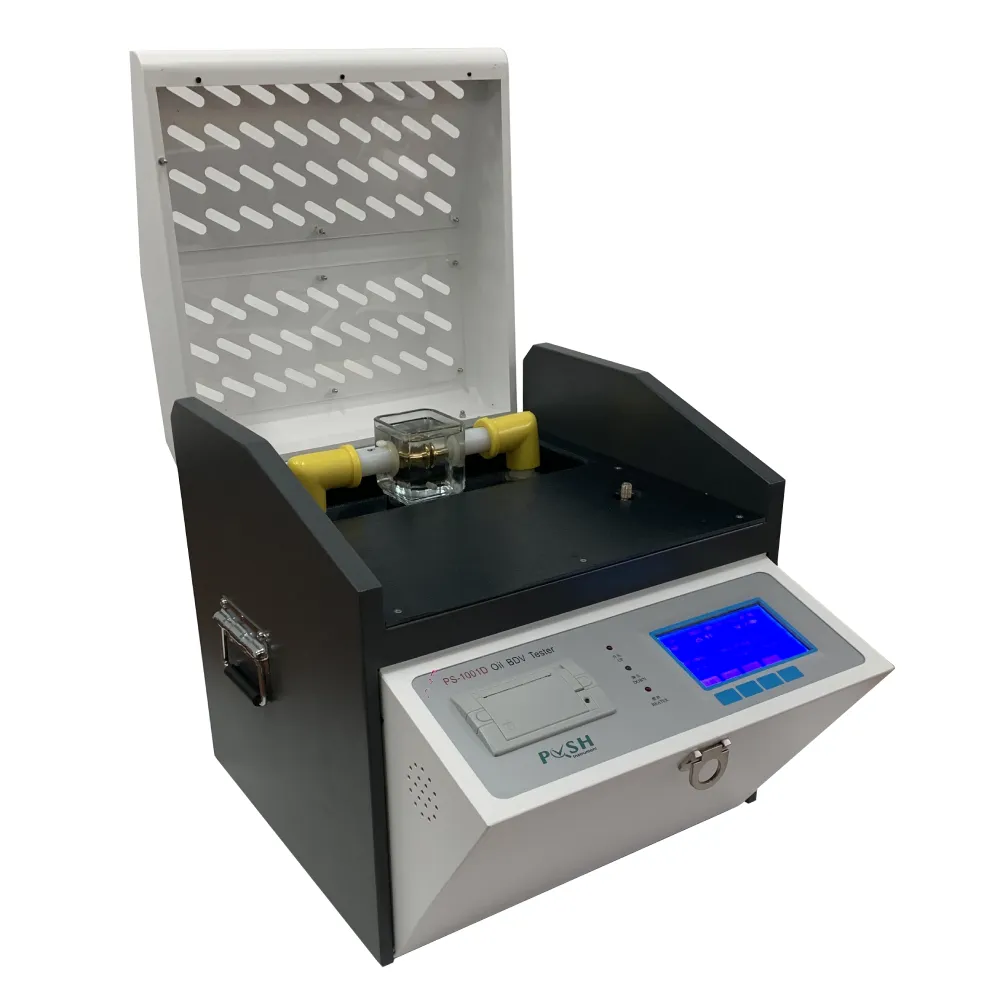

breakdown strength of transformer oil

Testing Breakdown Strength

To ensure the reliability of transformers, it is standard practice to conduct breakdown strength tests on transformer oil. The most common method involves using a standardized test cell, which typically has two electrodes placed a specific distance apart. A controlled voltage is applied, and the breakdown strength is determined when the oil begins to conduct electricity.

Regular testing is critical because it helps predict potential failures and allows for the timely maintenance of transformers. Oil samples should be taken periodically, especially in high-stress environments, to monitor changes in properties that could indicate degradation.

Importance of Maintaining High Breakdown Strength

Maintaining a high breakdown strength in transformer oil is essential for several reasons

- Safety Insulating oil with low breakdown strength can lead to electrical failures, which may result in fires or explosions, posing significant safety risks.

- Reliability Transformers are pivotal in power distribution. A failure in one transformer can lead to extensive outages, emphasizing the need for reliable insulation properties.

- Cost-effectiveness Regular monitoring and maintenance can prevent costly repairs and downtime by addressing issues before they escalate into more significant problems.

Conclusion

In summary, the breakdown strength of transformer oil is a critical parameter that underpins the safe and efficient operation of power transformers. Through understanding the factors affecting it, conducting regular tests, and maintaining best practices for oil management, electrical utilities can enhance the reliability and longevity of their transformers. As technology continues to evolve, it is essential to stay informed about advancements in transformer oil formulations and testing methods to ensure optimal performance in the ever-growing energy sector.

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025