English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Exploring the Role of Pi Test in Enhancing Transformer Performance

Understanding the PI Test in Transformer Analysis

Transformers are integral components in electrical engineering, primarily used for voltage transformation in power systems. As with any electrical device, ensuring their reliability and efficiency is imperative. One method of ensuring a transformer operates effectively and safely is through the Power Factor (PI) test. This article delves into what the PI test entails, its significance, and the methodologies involved.

What is the PI Test?

The PI test, or Power Factor Impedance test, is a diagnostic procedure used to evaluate the insulation quality of transformers. Insulation is crucial as it prevents electrical leaks and short circuits. Over time, factors such as moisture, temperature fluctuations, and electrical stresses can degrade insulation materials, potentially leading to catastrophic failures.

The PI test helps assess the insulation resistance of a transformer by quantifying the power factor, which is the ratio of the real power flowing to the load and the apparent power in the circuit. It involves applying a specified voltage to the transformer’s insulation system and measuring the resultant current. The test calculates the power factor based on the current's phase relationship with the applied voltage.

Importance of the PI Test

1. Assessment of Insulation Condition The key purpose of the PI test is to determine the integrity of the insulation system. If the insulation is compromised, the internal current can lead to unexpected failures, downtime, and financial losses. Regular PI tests can help predict insulation deterioration.

2. Preventive Maintenance Conducting this test periodically aids in preventive maintenance strategies. By identifying potential issues before they escalate, engineers can schedule repairs or replacements, ensuring the transformer operates within optimal parameters.

3. Safety Assurance Electrical systems can pose significant safety risks if not properly maintained. The PI test helps in identifying insulation weaknesses, thus safeguarding both personnel and equipment from electrical hazards.

4. Compliance and Standards Many industries are governed by strict regulatory standards concerning electrical equipment. The PI test helps ensure compliance with international and local regulations, promoting safe and efficient operation.

Conducting the PI Test

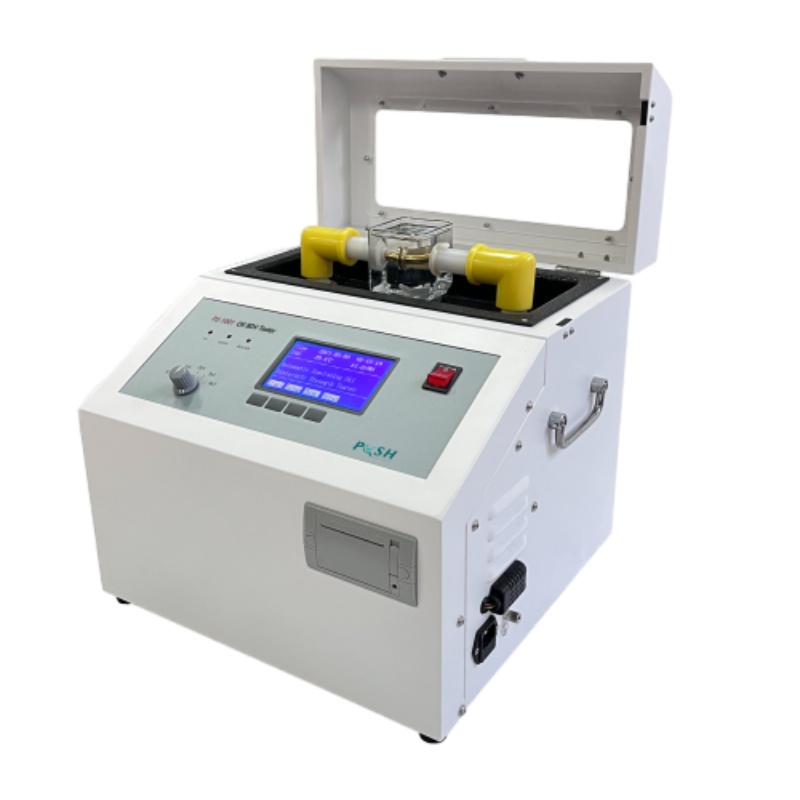

pi test in transformer

The procedure for conducting a PI test comprises several steps

1. Preparation The transformer must be de-energized and disconnected from the power supply. Safety precautions should be taken to prevent hazards.

2. Equipment Setup The testing equipment, typically a power factor tester, is set up to apply a specified AC voltage to the insulation. The voltage level should comply with the manufacturer’s specifications and standards.

3. Performing the Test The tester applies the AC voltage across the transformer’s winding insulation while measuring the current. The instrument calculates the power factor based on the obtained data.

4. Data Analysis The results are analyzed to determine the insulation’s condition. A low power factor indicates poor insulation, while a higher value suggests good insulation integrity.

5. Documentation It is crucial to document the results for future reference and trend analysis. This documentation can help in planning maintenance schedules and budgeting for transformer refurbishments or replacements.

Interpreting Results

The results of the PI test are typically expressed as a power factor value, which can range from 0 to 1. A low power factor (below 0.5) suggests significant insulation degradation, necessitating urgent attention. A power factor above 0.5 but below 0.85 indicates potential issues that should be monitored. Values above 0.85 are considered healthy, indicating good insulation condition.

Conclusion

The PI test for transformers is an essential diagnostic tool in electrical engineering. Its role in assessing insulation quality, supporting preventive maintenance, ensuring safety, and complying with industry standards underscores its importance. Regular testing not only prolongs the life of transformers but also enhances the reliability of electrical systems, contributing to safer operational environments. By understanding and implementing the PI test, electrical engineers can ensure transformers operate efficiently and effectively for years to come.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025