English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Exploring the Applications and Benefits of Tan Delta Testing in Electrical Insulation

Understanding the Tan Delta Test A Vital Tool in Electrical Engineering

The tan delta test, often referred to as the dissipation factor test, is a critical measurement used in the field of electrical engineering to assess the insulation properties of electrical equipment, particularly transformers, cables, and capacitors. This test evaluates the efficiency and reliability of insulating materials by measuring the loss of energy in the insulating medium and is essential for the maintenance of high-performance electrical systems.

Fundamentals of the Tan Delta Test

At its core, the tan delta test revolves around the concept of capacitance in electrical insulation systems. When an AC voltage is applied to an insulating material, it allows a certain amount of current to pass through. This current can be divided into two components the capacitive current (which is in phase with the voltage) and the resistive current (which is out of phase with the voltage).

The ratio of these two currents is known as the tan delta (or δ, the dissipation factor), and it quantifies the inefficiency in the insulation material. A lower tan delta value indicates better insulation characteristics and minimal energy loss, while a higher value points toward deterioration or potential failure of the insulation.

Importance of the Tan Delta Test

The significance of the tan delta test cannot be overstated. As electrical systems operate under various environmental conditions and loads, insulation can degrade over time. Factors such as moisture ingress, thermal aging, chemical exposure, and physical damage can all adversely affect insulating materials. By regularly conducting tan delta tests, engineers can detect early signs of insulation failure before they lead to catastrophic events, thereby ensuring the safety and reliability of electrical systems.

1. Predictive Maintenance One of the primary benefits of the tan delta test is its role in predictive maintenance programs. By monitoring the health of insulation over time, organizations can schedule maintenance activities based on actual condition rather than time-based intervals. This proactive approach minimizes both operational downtime and repair costs.

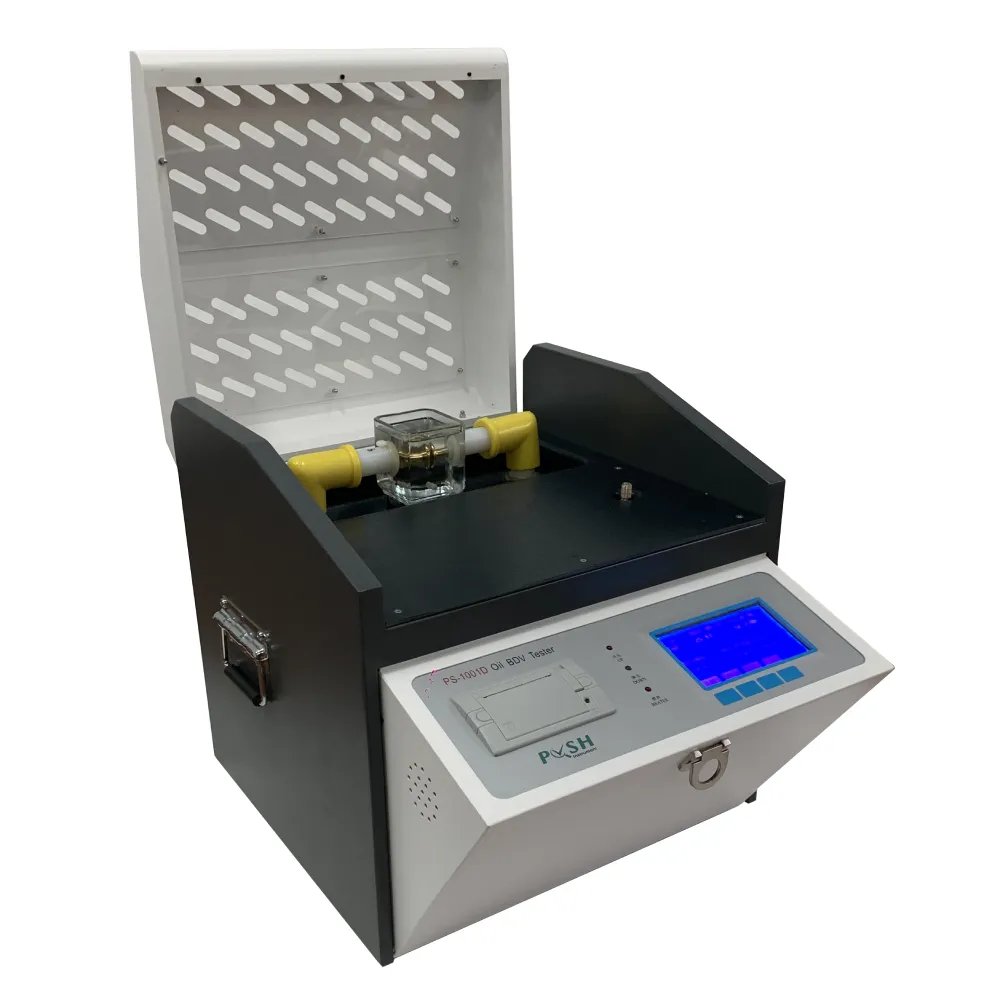

tan delta test set

2. Quality Control In the manufacturing of electrical equipment, the tan delta test serves as a quality control measure. Manufacturers can ensure that insulation materials meet specific electrical standards before their products are deployed in the field. This is particularly important for high-voltage applications where insulation integrity is critical for safe operation.

3. Asset Management For utility companies and industries relying on large electrical assets, understanding the condition of insulation helps in making informed decisions related to asset management. Investing in refurbishment, replacement, or operational upgrades can be guided through accurate data derived from tan delta testing.

Conducting the Tan Delta Test

The process of conducting a tan delta test involves several key steps

- Preparation The equipment must be isolated from the power supply and grounded to ensure safety during testing. - Measurement Setup Test leads are connected to the insulation, and the testing equipment is set up to apply a controlled AC voltage. - Data Acquisition The testing device measures both the resistive and capacitive currents, allowing for the calculation of the tan delta value. - Analysis The results are analyzed, typically comparing them to historical data and industry benchmarks to determine the condition of the insulation.

Conclusion

The tan delta test is an indispensable tool in the arsenal of electrical engineers and maintenance professionals. As the demand for reliable electrical systems continues to grow, understanding the condition of insulation through tan delta measurement becomes increasingly vital. By integrating this test into regular maintenance regimes, organizations can not only enhance the safety and efficiency of their operations but also prolong the lifespan of their electrical assets. Consequently, the tan delta test serves as a cornerstone for modern electrical engineering practices, ensuring that systems remain robust and dependable in an ever-evolving technological landscape.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025