English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

tangent delta test transformer

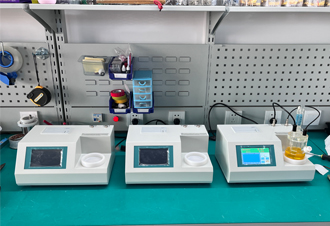

Understanding Tangent Delta Test Transformers A Key to Insulation Condition Assessment

Tangent Delta (TD) testing is a fundamental diagnostic method used to evaluate the insulation of electrical equipment, particularly transformers. In the realm of power engineering, the integrity of insulation systems is paramount, as they play a critical role in preventing electrical failures, which can lead to significant operational, safety, and financial ramifications. This article delves into the importance of tangent delta test transformers and how this testing method helps in assessing the condition of insulation materials.

The Principle of Tangent Delta Testing

The tangent delta is defined as the ratio of the resistive (dissipation) current to the capacitive (reactive) current in an insulation system when subjected to an AC voltage. This parameter provides insights into the dielectric properties of insulation materials. The tangent delta (often abbreviated as TD or tan δ) indicates the energy loss in the insulation due to its imperfections and potential moisture absorption.

In practical terms, tangent delta testing involves applying an alternating current to the transformer and measuring the phase angle difference between the current and the voltage. A higher tangent delta indicates increased dielectric losses, suggesting aging, moisture ingress, or contamination in the insulation system.

Importance of Tangent Delta Testing in Transformers

Transformers are crucial components in electrical distribution systems, converting voltage levels and ensuring efficient energy transfer. The reliability of a transformer significantly depends on the condition of its insulation. Periodic tangent delta testing serves several important functions

1. Condition Monitoring Regular TD testing allows operators to monitor the health of the insulation over time. By establishing baseline values, any deviations can prompt further investigation, helping to identify issues before they escalate into catastrophic failures.

2. Predictive Maintenance By analyzing the trends in tangent delta readings, maintenance can be scheduled based on the actual condition of the transformer rather than fixed intervals. This predictive approach improves the cost-effectiveness of maintenance strategies and minimizes unscheduled outages.

3. Risk Mitigation Understanding the insulation status helps in risk management. Transformers with deteriorating insulation can pose safety hazards, including fire risks and equipment failures. Early detection through TD testing enables timely intervention.

tangent delta test transformer

4. Compliance and Standards Many regulatory bodies and industry standards advocate for routine insulation testing to ensure safety and reliability. Tangent delta testing aligns with these requirements, providing documented evidence of maintenance practices.

Implementing Tangent Delta Testing

The implementation of tangent delta testing in transformers involves several key steps

- Preparation Isolate the transformer from the system to ensure safety and accuracy during testing. Follow all necessary lockout/tagout procedures.

- Test Setup Connect the testing equipment to the transformer, ensuring appropriate voltage levels are applied per manufacturer specifications.

- Data Collection Perform the measurements, ensuring to take note of ambient conditions, as temperature and humidity can impact readings.

- Analysis Compare the results against baseline data and industry standards. A systematic approach to analyzing trends over time is essential for effective condition monitoring.

- Reporting Document the findings and recommend subsequent actions, whether it be further testing, maintenance, or immediate repairs.

Conclusion

Tangent delta testing is an invaluable tool in the management of transformer insulation, providing insights that enhance safety and reliability in electrical systems. By regularly assessing insulation conditions, operators can detect issues early, optimize maintenance schedules, and extend the lifespan of transformers. In an industry where the cost of failure can be exceedingly high, investing in such diagnostic practices is not only prudent but essential for ensuring the seamless operation of critical electrical infrastructure.

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025