English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

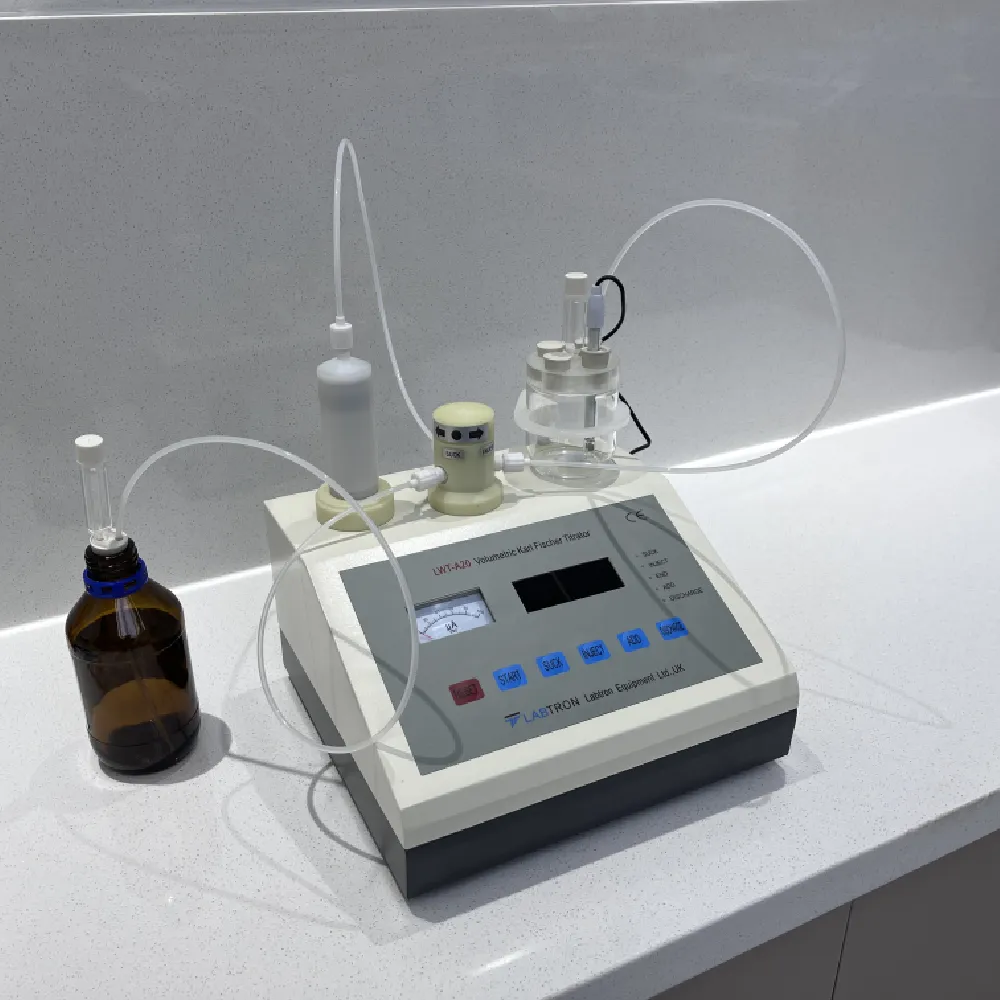

transformer oil flash point

Understanding Transformer Oil Flash Point Importance and Implications

Transformer oil is an essential insulating and cooling fluid used in electrical transformers and capacitors. Its primary role is to prevent overheating by dissipating heat generated during the operation of electrical equipment. However, one of the critical characteristics of transformer oil that must be monitored is its flash point, a key safety measure determining the flammability and thermal stability of the oil.

What is Flash Point?

The flash point of a substance is defined as the lowest temperature at which it can vaporize to form an ignitable mixture with air. For transformer oil, the flash point indicates the temperature at which the oil emits enough vapor to ignite. Generally, transformer oils have flash points ranging from 135°C to 190°C, depending on the refining process and additives used.

Importance of Flash Point

1. Safety Considerations Transformer oils, like any combustible materials, pose a fire risk during operation. An adequate flash point ensures that the oil does not ignite under normal operating conditions. It serves as a crucial parameter in establishing safety protocols for transformer operation and maintenance, minimizing the risk of fire hazards in substations and transformer stations.

2. Operational Efficiency Knowing the flash point helps in assessing an oil's thermal stability and performance capabilities. Oils with higher flash points tend to exhibit better thermal properties, contributing to improved heat dissipation and transformer efficiency. This aspect is particularly vital in high-capacity transformers that operate under considerable heat loads.

3. Regulatory Compliance Many industries that rely on electrical transformers must adhere to safety regulations set forth by various governance and safety bodies, such as the National Electrical Manufacturers Association (NEMA) or the Institute of Electrical and Electronics Engineers (IEEE). Regular testing of transformer oil’s flash point is necessary to comply with these regulations, ensuring that transformers are operated within safe parameters.

transformer oil flash point

4. Indication of Oil Degradation A decrease in the flash point over time can indicate the breakdown of transformer oil due to thermal aging or contamination with moisture or other substances. Regular monitoring of flash point can reveal potential issues with oil quality, prompting timely corrective actions such as oil replacement or treatment. This proactive approach can prevent transformer failures and extend the equipment's operational life.

Factors Affecting Flash Point

Several factors can impact the flash point of transformer oil

- Composition and Additives The chemical composition of transformer oil directly influences its flash point. Oils with high-quality base stocks and specific additives designed to enhance fire resistance generally exhibit higher flash points. Significant variances can occur due to the use of recycled oils versus virgin oils.

- Pollution and Contamination Water ingress and contamination from particulates can lower the flash point. Regular monitoring and maintenance of insulating oil are essential in mitigating these risks. Contaminated oil may not only lower the flash point but also affect the oil's insulating properties, leading to a higher risk of equipment failure.

- Temperature and Storage Conditions The way transformer oil is stored, including temperature variations and exposure to environmental conditions, can impact its flash point. Oils should be stored in controlled environments to maintain their properties and ensure optimal performance.

Conclusion

The flash point of transformer oil is a vital metric affecting the operational safety, efficiency, and longevity of electrical transformers. Regular testing and monitoring not only help in assessing the oil quality but also play a significant role in ensuring compliance with safety regulations. Understanding the importance of flash point and its influencing factors can aid operators and maintenance personnel in making informed decisions regarding transformer oil management, ultimately contributing to the safe and efficient operation of electrical infrastructures. As technology advances, ongoing research and development will continue to enhance the properties of transformer oils, further improving safety and performance standards in the electrical industry.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025