English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Testing Methods and Procedures for Substation Transformers in Power Systems

Substation Transformer Testing Ensuring Reliability and Efficiency

Transformers are the backbone of electrical substations, serving as critical components in the transmission and distribution of electrical energy. The efficacy and safety of these transformers are paramount, which is why thorough testing is crucial during their installation, maintenance, and operation. This article delves into the various testing methods used for substantiation transformers, highlighting their significance in ensuring reliability and operational efficiency.

The Importance of Transformer Testing

Transformers face a multitude of stresses during their operational lifespan, including electrical, thermal, and mechanical pressures. These stresses can lead to insulation deterioration, overheating, and, ultimately, failure. Therefore, implementing a robust testing regime is essential to identify potential issues before they escalate into costly outages or hazardous situations. Testing can be categorized into several types factory acceptance tests (FAT), site acceptance tests (SAT), and routine maintenance tests.

Factory Acceptance Tests (FAT)

Before a transformer is deployed in the field, it undergoes Factory Acceptance Tests. FATs verify that the transformer meets all design specifications and performance criteria. These tests typically include insulation resistance tests, power factor testing, winding resistance measurements, and short-circuit tests. FATs also ensure that all safety features, such as safety relays and circuit breakers, operate correctly.

One of the key aspects of FAT is verifying the transformer's electrical characteristics, such as voltage regulation, impedance, and efficiency. Adjustments can be made at the factory if the transformer does not meet specification standards, which helps to mitigate the risk of failure once the transformer is in service.

Site Acceptance Tests (SAT)

Once the transformer is delivered to the substation, Site Acceptance Tests are conducted to validate the unit's performance under real-world conditions. SATs are critical because they account for installation-related issues that may affect performance. These tests often include transformer oil tests, insulation resistance tests at various temperature conditions, and additional performance testing under load.

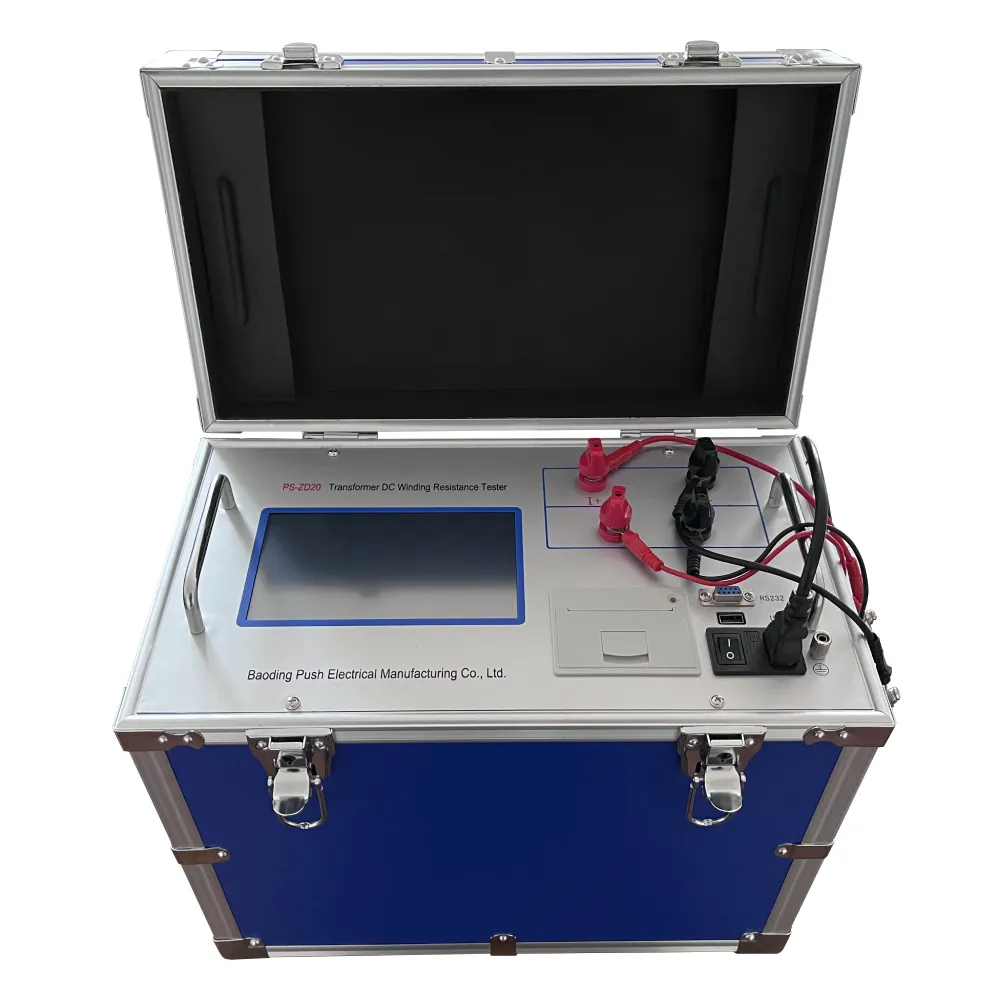

substation transformer testing

Safety is a primary focus during SAT. Proper grounding, the absence of leaks, and the functionality of safety devices are all evaluated to ensure a safe operational environment. Additionally, SAT provides an opportunity for the inspection of physical elements such as bushings and tap changers, which can be critical points of failure.

Routine Maintenance Testing

Transformers require ongoing maintenance throughout their operational life, and routine testing is crucial in preventing unexpected outages. Regular testing schedules include insulation resistance tests, power factor analysis, and thermal imaging assessments. These tests help in the early detection of insulation degradation, potential overheating, and other significant wear-and-tear issues.

Thermal imaging, for example, allows engineers to visualize heat patterns in real time, identifying hotspots that may indicate improper connections or failing components. Routine maintenance not only ensures continued performance but also extends the life of the transformer, providing a cost-effective solution to managing electrical infrastructure.

Emerging Technologies in Transformer Testing

With advancements in technology, testing methods for substational transformers are becoming more sophisticated. The introduction of smart sensors and diagnostic tools enables real-time monitoring of transformer health. These devices can assess various parameters continuously, allowing for predictive maintenance rather than reactive measures.

Artificial intelligence (AI) and machine learning algorithms are also increasingly being integrated into testing processes. By analyzing historical data and performance trends, these technologies can predict when a transformer is likely to fail or require maintenance, optimizing resource allocation and minimizing downtime.

Conclusion

Substation transformer testing plays a vital role in ensuring the reliability and safety of electrical infrastructure. Through comprehensive testing methods such as FAT, SAT, and routine maintenance, utilities can identify potential issues before they result in critical failures. With the advent of new technologies, the field of transformer testing is evolving, enabling more proactive approaches to maintenance and safety. As the demand for reliable energy continuously grows, investing in robust testing regimes will be indispensable in maintaining the integrity of electrical substations and the broader power distribution network.

-

Transformer Test Essentials: Insulating Oil Tester and TypesNewsMay.30,2025

-

Grease Testers and Oil Determination OverviewNewsMay.30,2025

-

Exploring Electricity Usage Testers and GeneratorsNewsMay.30,2025

-

Essential Guide to Transformer Oil Testing ToolsNewsMay.30,2025

-

Ensuring Safety with a Circuit Breaker FinderNewsMay.30,2025

-

Electrical Safety Tools Hipot, Dielectric, VLF TestersNewsMay.30,2025