English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

hi pot testing medium voltage cable

Hi-Pot Testing for Medium Voltage Cables Ensuring Reliability and Safety

High-Potential (Hi-Pot) testing is a critical procedure in the electrical industry, primarily used to assess the integrity and safety of insulation in medium voltage cables. This testing technique is essential for ensuring that cables can operate reliably under normal conditions and withstand potential fault conditions. In this article, we will explore the importance of Hi-Pot testing, how it is performed, the standards associated with it, and considerations for effective implementation.

Understanding Hi-Pot Testing

Hi-Pot testing involves applying a high voltage to a cable to ensure that its insulation is capable of withstanding electrical stresses. The primary goal is to identify any weaknesses or defects in the insulation that could lead to a failure during operation. This type of testing is particularly vital for medium voltage cables, typically rated between 1 kV and 35 kV, which are commonly used in power distribution systems to deliver electricity from substations to industrial and commercial infrastructures.

Importance of Hi-Pot Testing

Insulation failures can result in catastrophic consequences, including equipment damage, operational downtime, and safety hazards such as electrical fires or personnel injury. Hi-Pot testing serves as a preventative measure to avoid such incidents. By ensuring that insulation can handle the expected voltage levels, utilities and industries can mitigate the risks associated with power distribution. Furthermore, routine Hi-Pot testing can extend the lifespan of cables and reduce maintenance costs by identifying issues before they escalate.

The Process of Hi-Pot Testing

The Hi-Pot testing process usually consists of a few key steps

1. Preparation Before conducting the test, technicians must disconnect the cable from any live circuits. Safety procedures must be followed, including wearing appropriate personal protective equipment (PPE) and ensuring that the testing environment is safe.

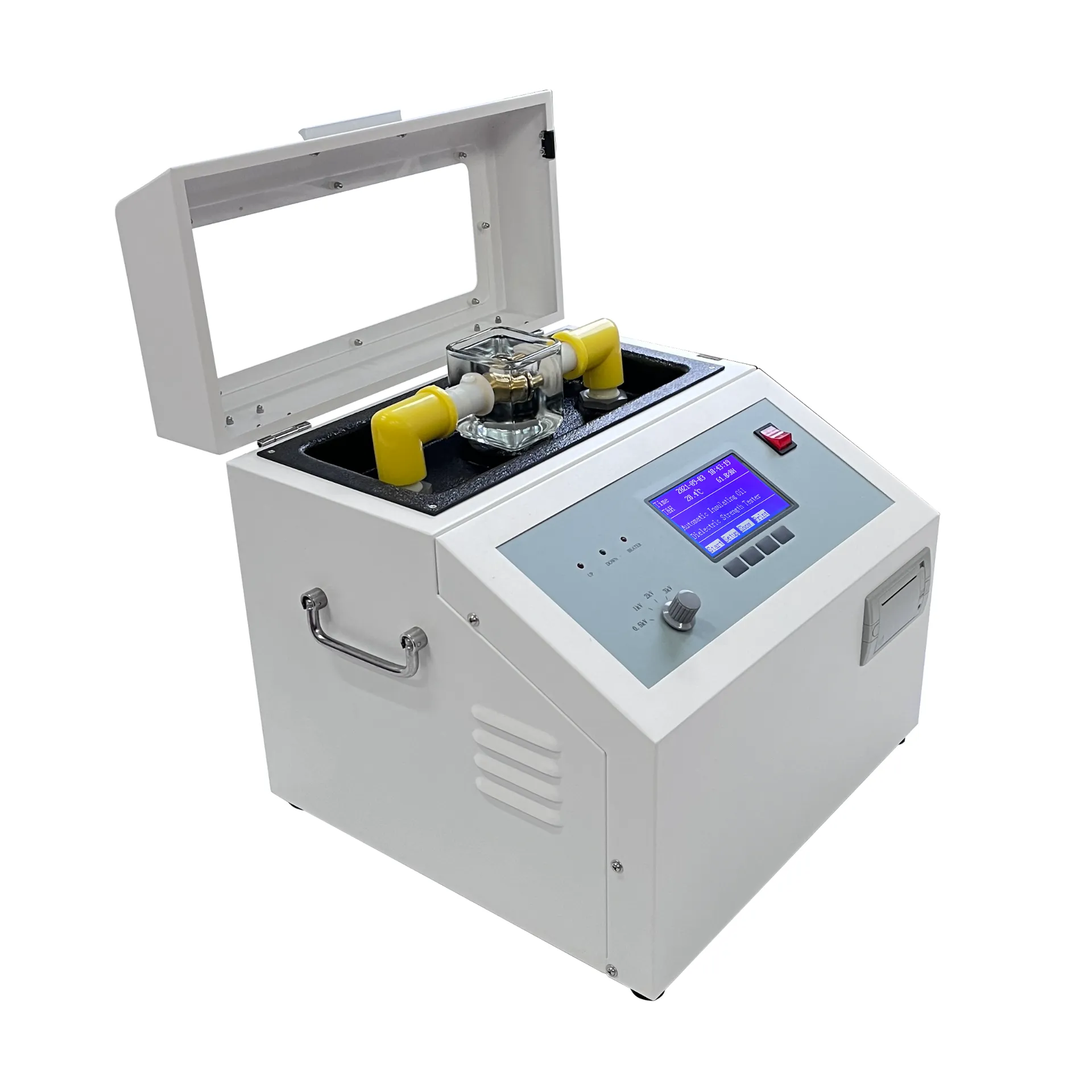

2. Setup The Hi-Pot tester is connected to the cable. One end of the cable is connected to the testing device, while the other end is grounded. The tester applies a specified voltage, which is usually higher than the cable's operating voltage by a predetermined factor, to the cable. The voltage level and testing duration depend on industry standards and the specific cable rating.

3. Testing As the high voltage is applied, the tester monitors the insulation for any signs of breakdown. This may manifest as a current surge, which indicates that the insulation is failing. The test may last anywhere from a few seconds to several minutes, depending on the established protocols.

hi pot testing medium voltage cable

4. Analysis After the test, the recorded data is analyzed. A successful test indicates the cable's insulation is intact and suitable for operation, while any failures call for further investigation, such as visual inspections or dielectric testing.

Standards and Recommendations

Hi-Pot testing should be conducted following recognized industry standards, such as those set by the National Electrical Manufacturers Association (NEMA) and the Institute of Electrical and Electronics Engineers (IEEE)

. These guidelines specify voltage levels, timing, and testing protocols to ensure consistent and reliable results.One crucial recommendation is to avoid over-stressing the insulation during testing. Excessive voltage can cause damage to otherwise sound cables. Consequently, the testing voltage should be within manufacturer specifications, typically ranging from 2.5 to 3 times the operating voltage.

Considerations for Effective Hi-Pot Testing

When implementing Hi-Pot testing, it is essential to consider the following

- Frequency Regular testing routines should be established based on the environment and operational demands. Cables in harsh conditions may require more frequent testing. - Documentation Keeping detailed records of testing procedures, results, and any corrective actions taken is vital for compliance and future reference.

- Skilled Personnel Only trained and experienced personnel should conduct Hi-Pot tests, as improper execution can lead to inaccurate results or unsafe conditions.

- Post-Test Procedures After testing, it's crucial to ensure that the cables are adequately grounded and safely reconnected to the system before returning to service.

Conclusion

Hi-Pot testing is an invaluable tool for ensuring the reliability and safety of medium voltage cables in electrical systems. By implementing thorough testing protocols and adhering to industry standards, organizations can significantly reduce the risk of insulation failures and their associated consequences. This proactive approach not only protects equipment and personnel but also contributes to the overall efficiency of power distribution networks.

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025