English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

250v insulation resistance test

Understanding 250V Insulation Resistance Testing

Insulation resistance testing is a crucial aspect of electrical maintenance and safety. At its core, this process involves evaluating the integrity of electrical insulation in cables, motors, transformers, and other electrical apparatus. Among the various voltage levels used in insulation testing, a 250V insulation resistance test is particularly common, especially in low-voltage electrical systems. This article aims to delve into the significance, methodology, and interpretation of the results from a 250V insulation resistance test.

Why Perform Insulation Resistance Testing?

Electrical insulation serves the vital function of preventing electrical leakage and ensuring safe operation. Over time, insulation can degrade due to environmental factors like moisture, temperature changes, and physical wear. This degradation can lead to reduced performance, risk of electrical shock, and potential fire hazards. Therefore, regular insulation resistance testing is essential for ensuring the reliability and safety of electrical installations.

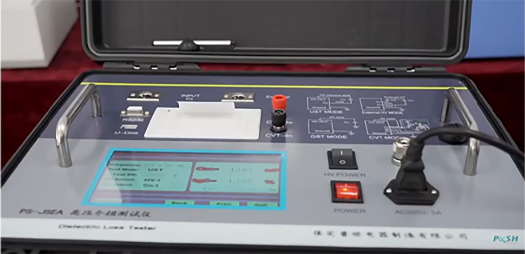

Equipment Used for Testing

A typical insulation resistance test is conducted using an insulation resistance tester, also known as a megohmmeter. This device applies a specified voltage (in this case, 250V) to the insulation material and measures the resistance of the insulation. The testing equipment usually features an assortment of settings, allowing the user to select a suitable voltage level for the specific application.

The Testing Process

1. Preparation Before conducting an insulation resistance test, it is crucial to ensure that the circuits are de-energized and properly isolated. Disconnect the equipment from the power supply to prevent any accidental shock or damage to the tester.

3. Performing the Test Set the tester to the 250V range and initiate the test. The tester will apply the voltage across the insulation and measure the resistance, usually displaying results in megohms (MΩ).

250v insulation resistance test

4. Duration of the Test The duration of testing can vary based on the standards used, but a typical test might last anywhere from 30 seconds to several minutes. This allows the tester to take an accurate reading as the insulation’s dielectric properties stabilize.

Interpreting the Results

The outcome of a 250V insulation resistance test is straightforward a higher resistance value indicates good insulation integrity, while a lower resistance value suggests potential failure points or moisture ingress. General guidelines for interpreting the results include

- Resistance greater than 1 MΩ Indicates healthy insulation, suggesting that the insulation is in good condition. - Resistance between 0.1 MΩ and 1 MΩ Suggests that the insulation may be deteriorating, and further investigation or remedial action should be considered. - Resistance less than 0.1 MΩ Indicates poor insulation, requiring immediate attention as it may pose serious safety and operational risks.

Factors Influencing Test Results

Several factors can influence the results of an insulation resistance test

- Environmental Conditions High humidity or temperature can affect resistance measurements. Ideally, tests should be conducted under consistent conditions. - Age of Equipment Older equipment is more prone to insulation degradation, necessitating more frequent testing. - Presence of Contaminants Dirt, dust, or chemical residues on insulation surfaces can lead to misleading low readings.

Conclusion

Regularly conducting a 250V insulation resistance test is a proactive approach to electrical maintenance, ensuring the safety and reliability of electrical installations. By understanding how to perform these tests and interpret the results, electrical professionals can prevent potential failures, minimize downtime, and enhance overall safety. As a best practice, insulation resistance testing should be part of a routine maintenance program, helping safeguard both personnel and equipment in today’s increasingly electrified environment.

-

Transformer Test Essentials: Insulating Oil Tester and TypesNewsMay.30,2025

-

Grease Testers and Oil Determination OverviewNewsMay.30,2025

-

Exploring Electricity Usage Testers and GeneratorsNewsMay.30,2025

-

Essential Guide to Transformer Oil Testing ToolsNewsMay.30,2025

-

Ensuring Safety with a Circuit Breaker FinderNewsMay.30,2025

-

Electrical Safety Tools Hipot, Dielectric, VLF TestersNewsMay.30,2025