English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

tan delta test of transformer winding

Tan Delta Test of Transformer Winding

The Tan Delta test, also known as the Power Factor test, is a vital diagnostic tool used to assess the insulation condition of transformer windings. Transformers, being critical components in power transmission and distribution systems, require regular maintenance and testing to ensure reliability, efficiency, and longevity. One such method for evaluating insulation performance is the Tan Delta test, which provides valuable insights into the quality and integrity of transformer winding insulation.

Understanding Tan Delta

Tan Delta (tan δ) is a function of the dielectric losses in an insulating material, represented mathematically as the ratio of the resistive current to the capacitive current in the insulation system. It reflects the phase difference between the applied voltage and the resulting current. In practical terms, a lower tan delta value indicates better insulation quality, while a higher tan delta value may signify deterioration or faults within the insulation. The test is typically performed at various frequencies, and the results can help identify areas needing attention before they lead to transformer failure.

Importance of the Tan Delta Test

Transformers operate under high voltages and harsh conditions, making their insulation systems susceptible to degradation over time due to factors such as thermal stress, moisture ingress, and electrical stresses. The Tan Delta test serves several purposes

1. Early Detection of Insulation Degradation By measuring the tan delta value at regular intervals, operators can detect early signs of insulation deterioration. An increase in tan delta can indicate the presence of moisture, contamination, or thermal aging.

2. Maintenance Planning The test results can help operators decide when to perform maintenance, repair, or replacement of transformer components, thus averting unexpected downtime and reducing operational costs.

3. Quality Control during Manufacturing The Tan Delta test can also be employed during the manufacturing of transformers. It helps manufacturers ensure that insulation materials meet specified standards and are free from defects before deployment.

tan delta test of transformer winding

4. Risk Assessment By analyzing tan delta values over time, operators can assess the risk levels associated with transformer operations. Higher values might necessitate immediate interventions to prevent catastrophic failures.

The Testing Procedure

Conducting a Tan Delta test involves several key steps

1. Preparation Ensure that the transformer is offline and properly grounded. Disconnect any auxiliary equipment to isolate the transformer for testing.

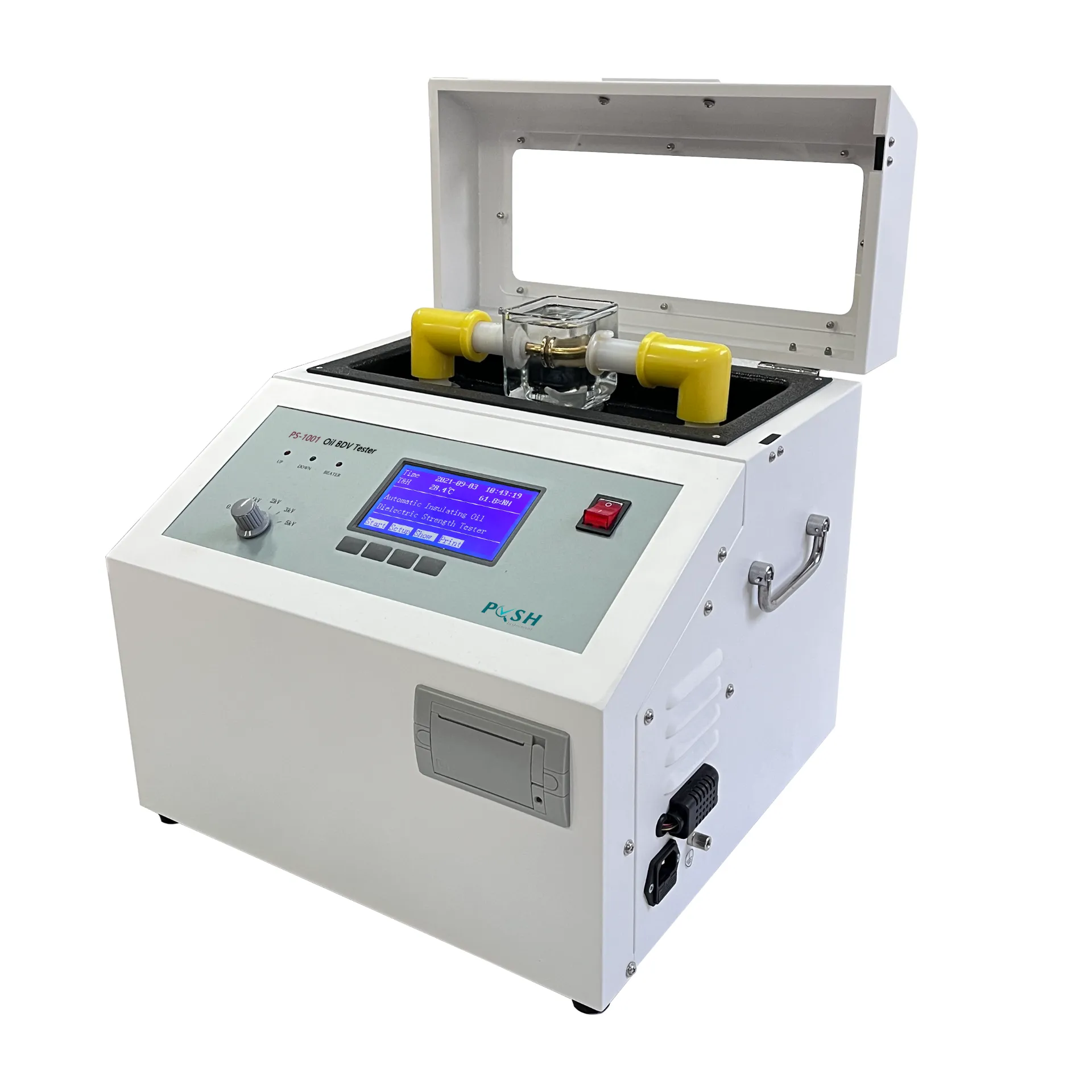

2. Testing Equipment Use a calibrated tan delta test equipment that applies an alternating voltage to the insulation and measures both the current and voltage.

3. Measurement The equipment applies a test voltage, and the tan delta value is calculated based on the phase shift between the charging and discharging currents.

4. Data Analysis Compare the measured tan delta values with historical data and manufacturer specifications. Look for trends such as increasing values over time, which may necessitate further investigation.

Conclusion

The Tan Delta test of transformer windings serves as a crucial technique for ensuring the reliability and safety of electrical power systems. By regularly monitoring the insulation condition, operators can proactively manage maintenance and repairs, thereby enhancing the lifespan of transformers and minimizing the risk of unexpected failures. With advancements in technology, the accuracy and efficiency of the Tan Delta test continue to improve, making it an indispensable part of transformer health assessment strategies. As electrical systems become more complex and integrated, ongoing diagnostics like the Tan Delta test will remain paramount in maintaining the integrity and performance of critical infrastructure in the power industry.

-

Using Distillation Range Testers in the Food and Beverage IndustryNewsApr.16,2025

-

The Impact of IoT on Distillation Range Tester PerformanceNewsApr.16,2025

-

The Best Distillation Range Testers for Extreme ConditionsNewsApr.16,2025

-

How Distillation Range Testers Save Time and MoneyNewsApr.16,2025

-

Distillation Devices for Advanced Separation TechniquesNewsApr.16,2025

-

Common Mistakes to Avoid When Using a Distillation Range TesterNewsApr.16,2025