English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

dielectric test on transformer

Dielectric Test on Transformers Ensuring Reliability and Safety

Transformers play a crucial role in the electrical power supply system, facilitating the efficient transmission and distribution of electricity. As critical components in electrical networks, transformers must operate safely and reliably under various conditions. One of the essential tests conducted on transformers to ensure their integrity is the dielectric test. This article explores the importance, procedure, and implications of dielectric testing on transformers.

Understanding Dielectric Testing

Dielectric testing assesses the insulating properties of the transformer’s materials, particularly the insulation systems that separate conductors and prevent electrical failures. It helps identify weaknesses in the insulation that could lead to failure, breakdown, or excessive leakage currents. The integrity of the insulation system is vital to prevent short circuits, which can cause catastrophic failures, equipment damage, and safety hazards.

Typically, the dielectric strength is tested by applying a high voltage to the transformer windings. This voltage is significantly higher than what the transformer would normally experience in operation. The key objective is to verify that the insulation can withstand these high voltages without breaking down. The most common types of dielectric tests include

1. Power Frequency (AC) Dielectric Test This test applies an alternating current (AC) voltage at the power frequency (generally 50 or 60 Hz). It evaluates the insulation's performance under normal operating conditions.

2. DC Dielectric Test During this test, a direct current (DC) voltage is applied. The DC test is often used to diagnose insulation problems and to measure insulation resistance accurately.

3. Impulse Voltage Test This test simulates lightning strikes or switching surges. It applies a high-voltage impulse to check the insulation's performance against transient voltages.

These tests provide essential data regarding the dielectric breakdown strength of transformer insulation and help in assessing its capability to resist electrical stress over its operational life

.The Testing Procedure

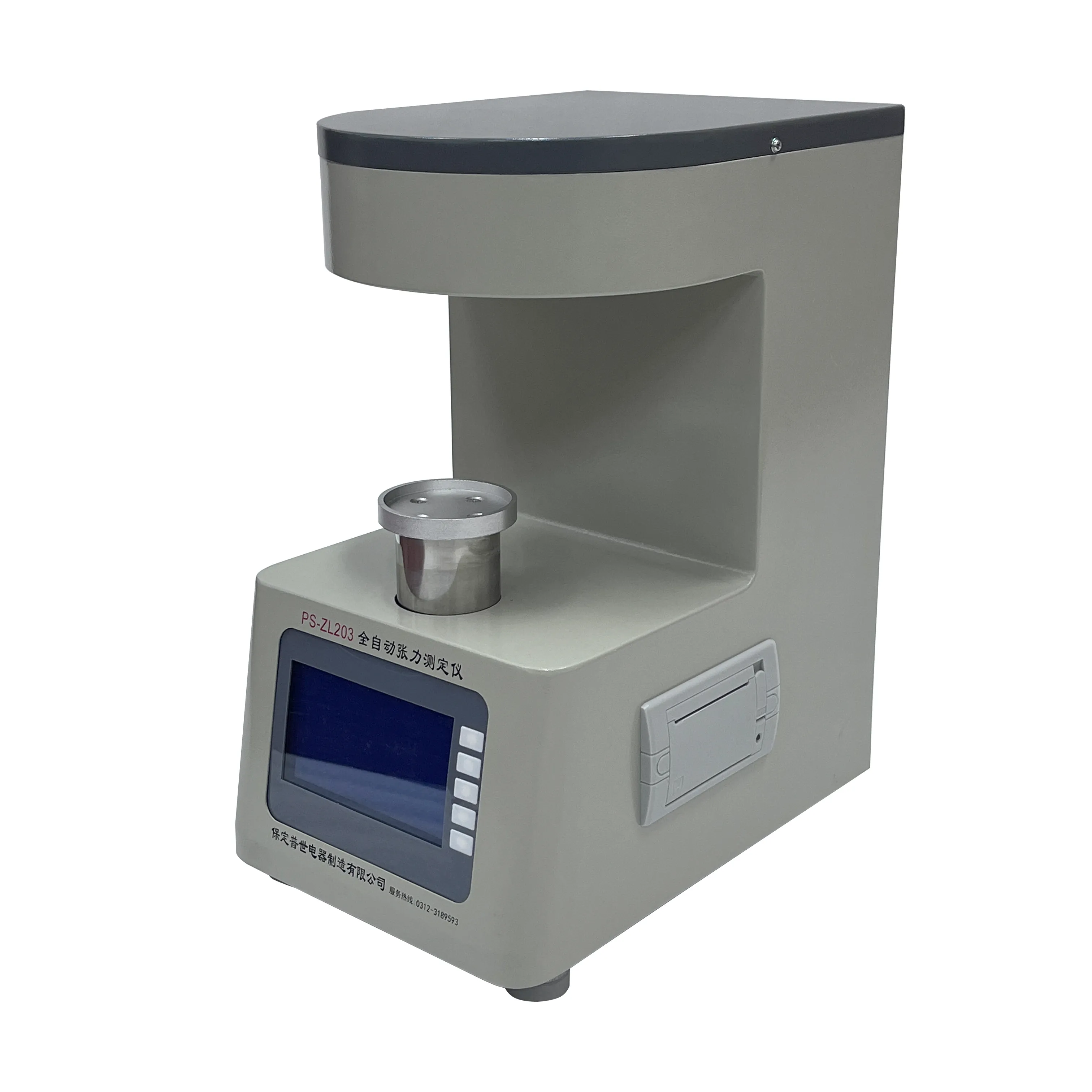

dielectric test on transformer

The dielectric testing procedure typically involves several steps

1. Preparation Before testing, transformers must be properly prepared, which includes de-energizing and disconnecting the unit from any load. All capacitive and inductive components must also be discharged to avoid reading errors or equipment damage.

2. Equipment Setup The dielectric testing equipment, usually a high-voltage transformer or capacitor bank, is connected to the transformer’s terminals according to the manufacturer's guidelines.

3. Testing The test is performed by gradually increasing the voltage to the specified testing level, holding it for a predetermined duration, usually 1 to 5 minutes. Throughout the test, measurements are taken to monitor the leakage current or any insulation breakdown that may occur.

4. Analysis After the test, the data collected is analyzed to determine if the transformer’s insulation meets the required specifications. If the insulation shows excessive leakage current or breakdown, further investigation is necessary to identify the root cause and remedial action.

Importance of Dielectric Testing

The significance of dielectric testing cannot be overstated. First and foremost, it enhances the safety of transformer operations. By ensuring that insulation systems are robust, utilities can prevent electrical failures that could lead to accidents or equipment damage. Secondly, routine dielectric testing contributes to the longevity of transformers. Identifying and addressing insulation deficiencies before they escalate can significantly extend the operational life of transformers.

Moreover, dielectric testing is crucial for compliance with international standards and regulations governing electrical equipment. Many industries mandate regular testing to ensure components meet safety and operational standards, thereby protecting both workers and infrastructure.

Conclusion

In conclusion, dielectric testing plays an indispensable role in the maintenance and reliability of transformers. By assessing the integrity of insulation systems, these tests safeguard not just the equipment involved but also the larger electrical supply ecosystem. Regular dielectric testing should be part of a comprehensive maintenance strategy, ultimately ensuring safety, efficiency, and longevity in transformer operations. As technologies evolve, further advancements in testing methods and equipment will help optimize the reliability of transformers in an increasingly demanding power landscape.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025