English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Evaluation of Electrical Insulation Quality Using the Tan Delta Method

Understanding the C Tan Delta Test Significance and Applications

The C tan delta test is a critical evaluation method used widely in various industries, particularly in the fields of material science and engineering. This test measures the dielectric properties of materials, specifically focusing on two key parameters capacitance (C) and the loss angle delta (tan δ). Understanding these parameters is essential for determining the suitability and performance of materials in specific applications.

What is the C Tan Delta Test?

At its core, the C tan delta test aims to assess how materials respond to electrical fields. The test is performed by subjecting a sample to alternating current (AC) at a specific frequency. The material's ability to store electrical energy (capacitance) alongside its ability to dissipate energy as heat (loss factor) are analyzed. The loss angle delta is calculated as the ratio of the resistive (loss) current to the capacitive (storage) current, leading to the expression tan δ. This value indicates the energy lost in the cycle of charging and discharging.

The significance of the test is manifold. A low tan δ value is generally indicative of a good insulating material, as it signifies minimal energy loss. In contrast, a high tan δ suggests poor insulation and significant energy loss, which can lead to overheating and potential failure in electrical applications.

Applications of the C Tan Delta Test

The C tan delta test finds applications across numerous fields

c tan delta test

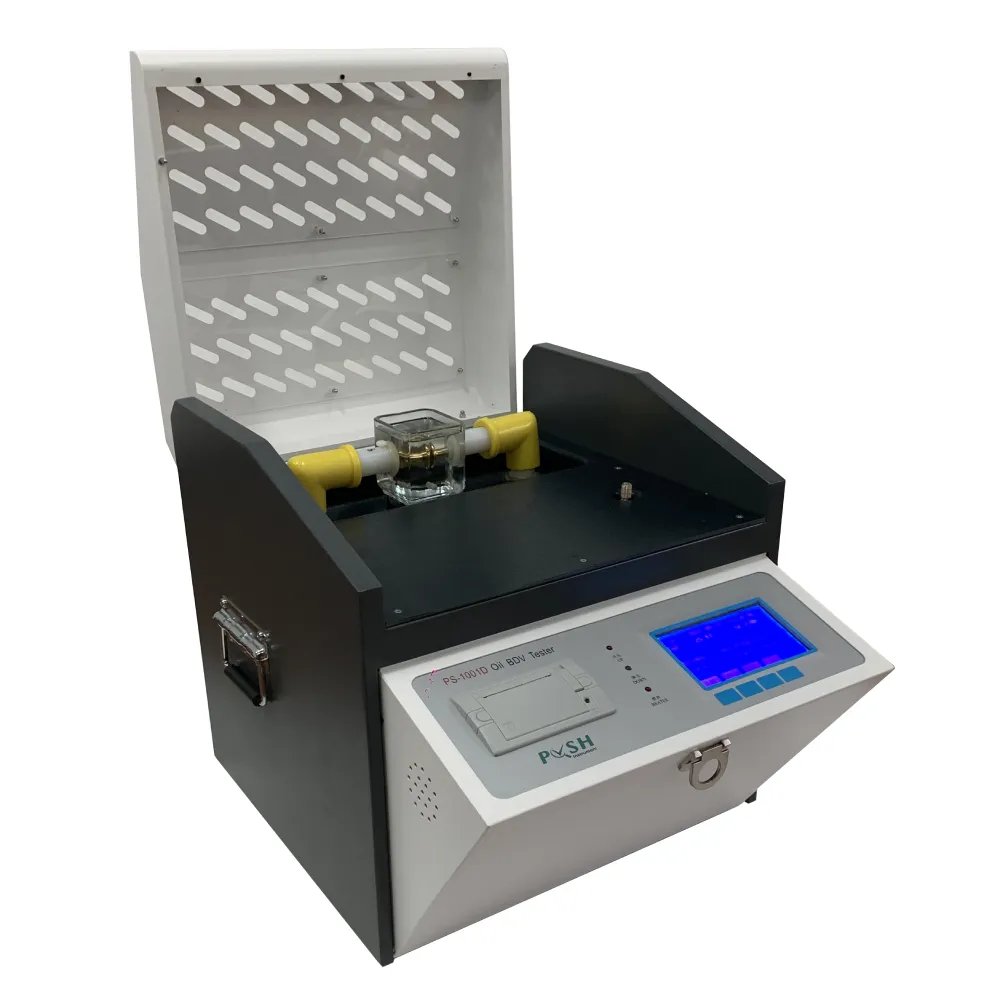

1. Electrical Insulation Assessment One of the primary applications of this test is in evaluating insulation materials used in power cables, transformers, and switchgear. It helps determine if the insulation is still effective or if it has degraded over time, thus enabling predictive maintenance and reducing the risk of failures in high voltage equipment.

2. Polymer and Composite Materials Testing The test is also vital in the development and quality control of polymers and composite materials. It helps manufacturers ensure that the materials can withstand electrical stresses while minimizing losses, which is particularly important in the automotive and aerospace industries.

3. Quality Control in Manufacturing Manufacturers often use the C tan delta test as part of their quality control processes. By regularly testing the dielectric properties of their products, they can ensure consistency and reliability, which is crucial for maintaining brand reputation and customer satisfaction.

4. Research and Development In research settings, the C tan delta test allows scientists and engineers to explore new materials and their applications. By understanding the dielectric properties of novel materials, researchers can innovate and create solutions that outperform traditional materials.

Conclusion

In summary, the C tan delta test is a crucial method for analyzing the electrical properties of materials, offering important insights into their performance in practical applications. Its ability to measure capacitance and energy loss makes it indispensable for industries relying on electrical insulation and material performance. As technology continues to evolve, the principles behind the C tan delta test will remain integral to material science and engineering, facilitating advancements that drive efficiency, safety, and sustainability in electrical systems.

By employing regular C tan delta testing, organizations can not only enhance product reliability but also extend the lifecycle of their materials, ultimately contributing to more sustainable practices. Therefore, the significance of this test cannot be understated, as it continues to play a pivotal role in technology and innovation across various sectors.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025