English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

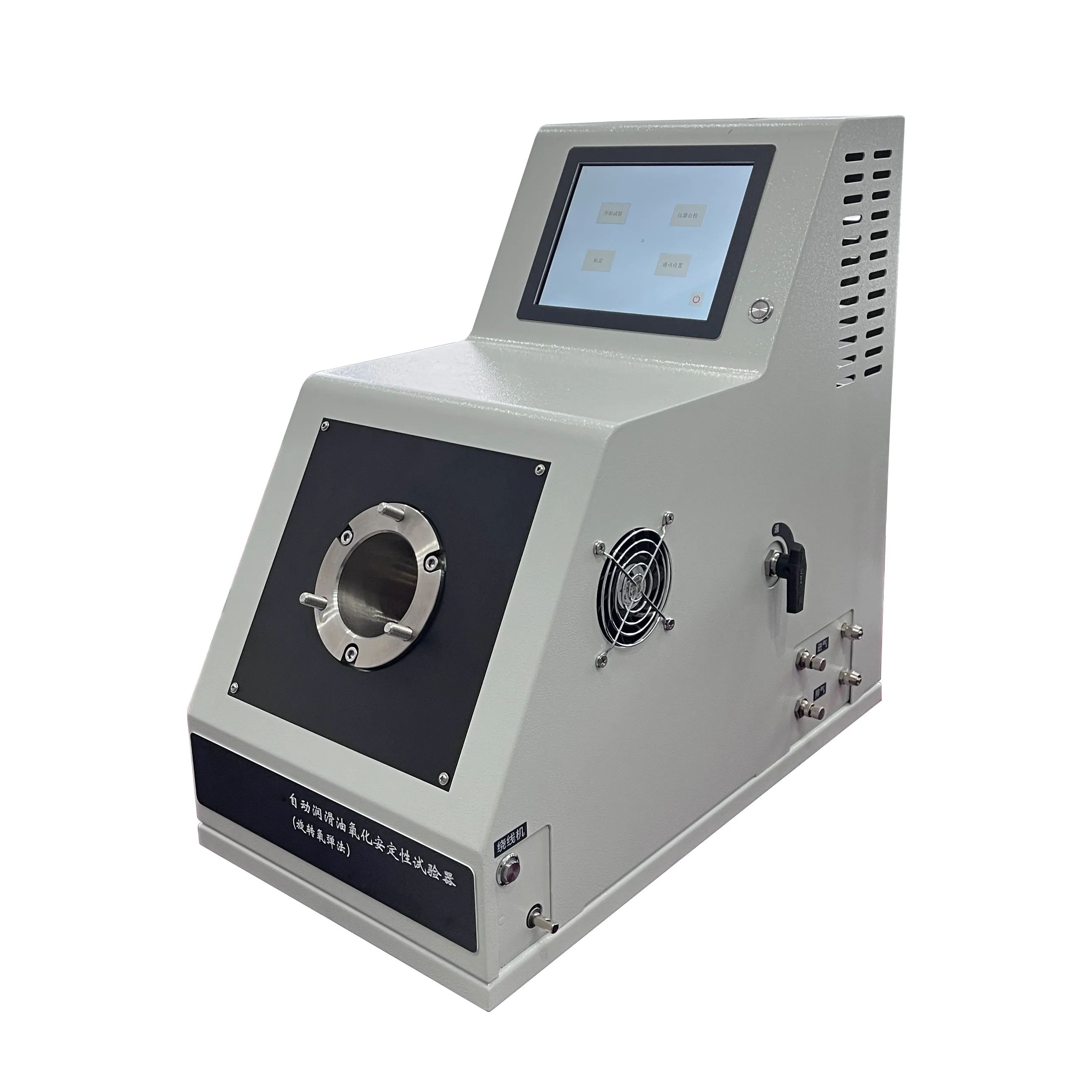

Automated Extraction of Knowledge for Efficient Distillation Processes and Techniques

Automated Distillation Revolutionizing the Separation Process

In the world of chemical engineering and industrial processes, distillation remains one of the most vital techniques for separating mixtures based on differences in their boiling points. However, traditional distillation methods often involve labor-intensive operations, require skilled personnel, and can be less efficient. Enter automated distillation, a groundbreaking approach that leverages technology to enhance the efficiency, precision, and safety of the distillation process.

Automated distillation systems utilize advanced technologies such as artificial intelligence, robotics, and real-time monitoring to streamline the distillation process. By integrating automation into distillation, industries can significantly reduce human intervention, which not only minimizes the risk of human error but also reduces labor costs. This transition towards automation is particularly important in sectors such as petrochemicals, pharmaceuticals, and food and beverage industries, where precision and efficiency are paramount.

One of the core benefits of automated distillation is its ability to optimize the separation process. Traditional distillation setups often operate under fixed parameters, which can lead to inefficiencies and suboptimal outcomes. Automated systems, on the other hand, are capable of making real-time adjustments based on feedback from various sensors that monitor temperature, pressure, and concentration levels. This dynamic capability enables the system to adapt to changing conditions, ensuring that the separation process maintains maximum efficiency throughout its operation.

Moreover, the integration of artificial intelligence (AI) into automated distillation systems can enhance decision-making processes. Machine learning algorithms can analyze historical data and predict optimal operating conditions, which not only improves the yield but also minimizes energy consumption. The ability to foresee and mitigate potential issues before they escalate allows for smoother operations and reduced downtime, ultimately leading to increased productivity.

automated distillation

Safety is another paramount concern in chemical operations. Automated distillation systems can be equipped with fail-safe mechanisms and emergency shut-off protocols that significantly enhance workplace safety. By reducing the need for human presence in potentially hazardous environments, these systems protect workers from exposure to harmful substances and reduce the likelihood of accidents.

Data analytics plays a crucial role in the modern landscape of automated distillation. With the rise of the Internet of Things (IoT), distillation units can be connected to centralized monitoring systems that provide detailed insights and performance metrics. Operators can access real-time data from remote locations, allowing for proactive management of the distillation process. This level of transparency fosters continuous improvement, as companies can assess the efficiency of their systems and make data-driven decisions to enhance performance.

The environmental impact of distillation processes cannot be overlooked. Traditional methods often lead to significant energy consumption and waste generation. Automated distillation seeks to address these concerns by optimizing energy usage through precise control of heating and cooling processes. By achieving higher purity levels in fewer cycles, automated systems can reduce waste and conserve valuable resources, thereby contributing to more sustainable industrial practices.

As industries continue to push for greater efficiencies and sustainability, the adoption of automated distillation systems is likely to accelerate. The technology not only promises improvements in operational efficiency and safety but also aligns with the global shift towards more sustainable and environmentally-friendly practices.

In conclusion, automated distillation represents a significant advancement in the field of separation processes. By leveraging automation, AI, and data analytics, industries can achieve unparalleled efficiency, safety, and environmental sustainability. As technology continues to evolve, the potential for automated distillation to transform sectors ranging from petrochemicals to pharmaceuticals is immense. As we look to the future, embracing these innovations will be key to meeting the challenges of production efficiency and sustainability.

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025