English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Closed Cup Flash Point Testing Methodology and Applications in Safety Evaluation

Understanding the Flash Point Closed Cup Test

The flash point closed cup test is a critical procedure in the field of materials safety and chemical analysis. This test determines the lowest temperature at which vapors of a volatile substance can ignite when exposed to an ignition source under specific conditions. Understanding the flash point is vital for evaluating the flammability and hazard risk associated with various materials, particularly in industries such as petrochemicals, paints, solvents, and pharmaceuticals.

In the closed cup method, a sample of the material is placed in a sealed container. The testing apparatus is designed to allow for minimal exposure to the atmosphere to prevent evaporation or contamination, which could skew the results. The temperature of the sample is gradually increased, and an ignition source, often a small flame or an electrical spark, is introduced at intervals. The flash point is defined as the lowest temperature at which the vapors above the liquid ignite momentarily and produce a flash.

One of the primary advantages of the closed cup method is its ability to provide a more controlled environment compared to open cup tests. Because the sample is sealed, volatile compounds cannot easily escape, ensuring accurate readings of the vapors' concentration. Moreover, this method is often more applicable in regulatory settings where safety and compliance are paramount.

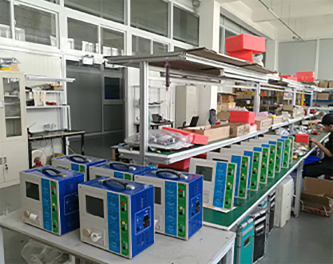

flash point closed cup test

Different standards and methods exist for conducting the flash point closed cup test, with the most common being the Pensky-Martens closed cup test and the Tag closed cup test

. The Pensky-Martens method is frequently used for substances that require precise measurements, while the Tag method is suitable for lighter materials and is considered less sensitive. Each method has its specific temperature ranges and testing protocols, which must be adhered to in order to guarantee reliability and reproducibility of results.The flash point is not only a regulatory requirement for hazardous materials but also serves as a fundamental parameter in product formulation and safety data sheets (SDS). Knowing the flash point allows manufacturers to design safer facilities, create proper storage conditions, and ensure compliance with fire safety regulations. Furthermore, it aids in risk assessment and emergency planning, particularly for industries that handle flammable substances.

Interpreting the results of the flash point closed cup test is crucial for end users. A low flash point indicates a higher risk of ignition at lower temperatures, necessitating stringent safety measures during production, transportation, and storage. Conversely, a higher flash point may suggest a safer profile, though it does not eliminate the necessity for careful handling and respect for associated risks.

In conclusion, the flash point closed cup test plays an essential role in ensuring materials' safety and compliance in diverse industries. By accurately determining the ignition risk of volatile substances, this test fosters a safer working environment and aids in preventing accidents related to flammable materials. As regulations continue to evolve, understanding and applying the results of flash point tests will remain an indispensable aspect of chemical safety management. Manufacturers, chemists, and safety professionals alike must prioritize these assessments to mitigate risks and protect both workers and the environment from the dangers posed by flammable substances.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025