English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Winding Resistance Measurement Techniques for Current Transformer Testing and Analysis

Winding Resistance Test of Current Transformers

Current transformers (CTs) play a vital role in power systems, enabling the safe measurement and monitoring of electric current. Ensuring the reliability and accuracy of these devices is crucial for effective grid management. One essential procedure for evaluating the performance of current transformers is the winding resistance test. This article outlines the significance, methodology, and benefits of conducting winding resistance tests on current transformers.

Importance of Winding Resistance Testing

Winding resistance tests are fundamental in assessing the integrity and functionality of current transformers. The primary purpose of this test is to measure the resistance of the transformer windings, which can indicate various factors such as connection integrity, quality of materials used, and the overall health of the transformer. Any increase in winding resistance may denote potential issues, such as loose connections, corroded contacts, or degradation of materials, which can lead to aging and reduced performance of the transformer.

Moreover, winding resistance measurements provide insight into the balanced performance of each winding. In a properly functioning current transformer, the resistance values of both primary and secondary windings should be relatively similar. Significant discrepancies can indicate faults that may impair the functionality of the transformer, causing inaccurate current readings and jeopardizing system safety.

Methodology of the Test

Conducting a winding resistance test on current transformers involves several steps to ensure accurate and reliable results.

1. Preparation Before starting the test, it’s essential to ensure that the CT is safely isolated from any live circuits. De-energizing the transformer and adhering to safety protocols is vital to protect personnel and equipment.

2. Testing Equipment A low-resistance ohmmeter, also known as a micro-ohmmeter, is typically used for this test. This instrument can measure low resistance values accurately, which is crucial since the winding resistance can be very low.

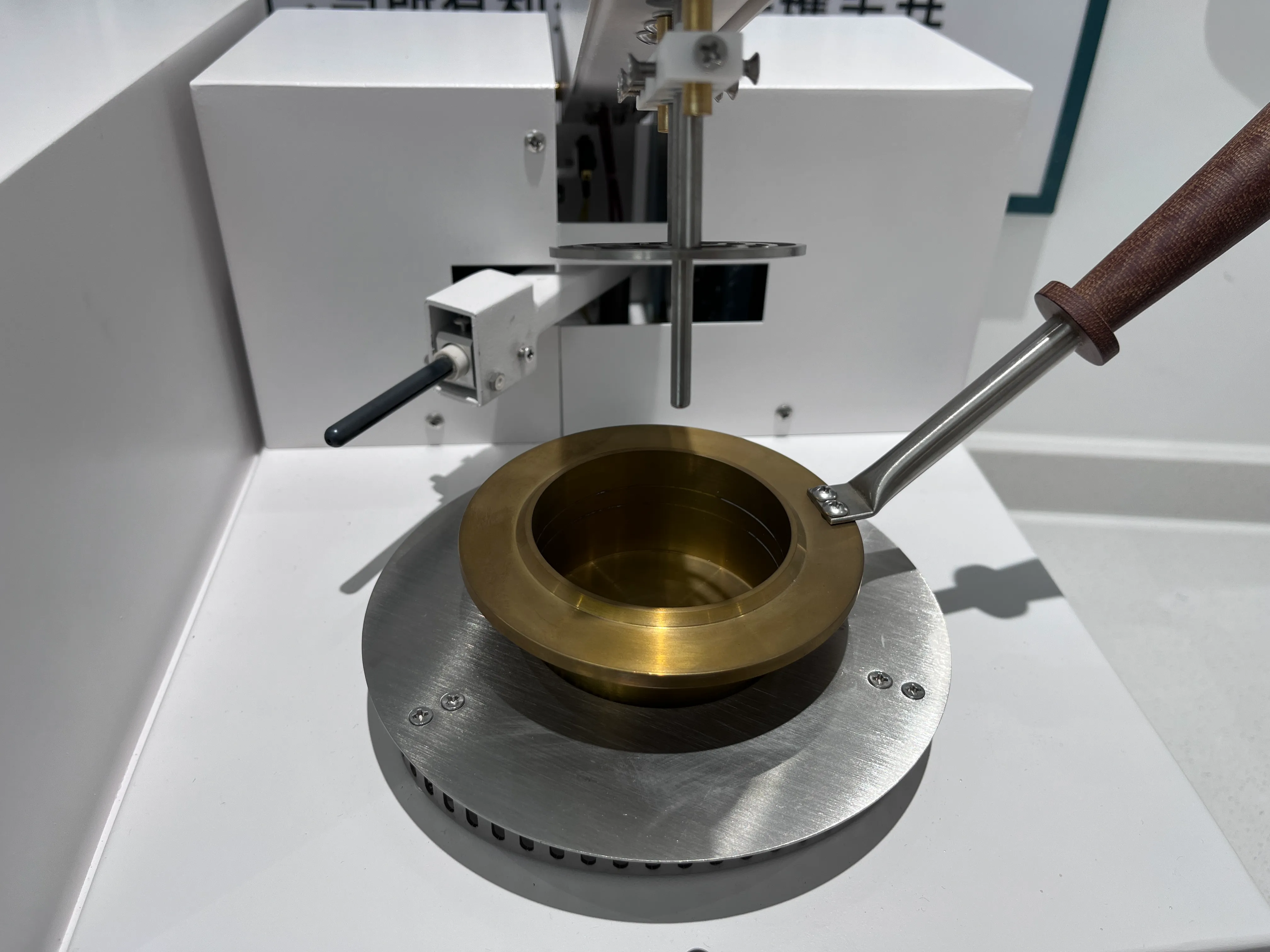

winding resistance test of current transformer

3. Connection The next step involves connecting the test leads from the ohmmeter to the terminals of the transformer windings. Care should be taken to ensure robust connections to avoid any additional resistance and ensure accurate readings.

4. Measurement The resistance of each winding is measured individually, taking multiple readings to account for any fluctuations. The measurements should be compared against the manufacturer’s specifications or previous test results to detect any deviations.

5. Analysis After collecting the data, the resistance values are analyzed. Any significant variations from expected resistance levels warrant further investigation to identify underlying issues.

Benefits of Winding Resistance Testing

Winding resistance testing provides numerous advantages, making it an essential aspect of transformer maintenance

- Prevention of Failures By identifying potential issues early, maintenance teams can address problems before they lead to transformer failure, reducing downtime and repair costs. - Improved Accuracy Ensuring that the windings are functioning correctly helps maintain the accuracy of current measurements, which is critical for system performance and reliability.

- Extended Lifespan Regular testing and subsequent maintenance contribute to the longevity of current transformers, ensuring they operate efficiently throughout their designed life.

- Safety Assurance Identifying and rectifying faults within current transformers enhances overall system safety, mitigating risks associated with equipment failures.

In conclusion, the winding resistance test is a crucial diagnostic tool for assessing the condition and performance of current transformers. Routine testing can significantly enhance reliability, improve measurement accuracy, and ensure the safety of electrical systems. Thus, power utilities and maintenance teams should prioritize regular winding resistance testing as part of their comprehensive maintenance programs for current transformers.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025