English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Advanced Equipment for Measuring Tan Delta in Electrical Insulation Testing

Understanding Tan Delta Test Equipment A Comprehensive Overview

Tan delta testing is an essential process used in the electrical and insulation industries to assess the integrity of insulating materials and components, particularly in high-voltage environments. This testing method helps organizations ensure the reliability and longevity of electrical equipment by measuring the dielectric properties of insulators. In this article, we will explore what tan delta testing is, the significance of tan delta test equipment, its operational principles, and its applications.

What is Tan Delta Testing?

Tan delta testing, often referred to as power factor testing, involves the measurement of the tangent of the loss angle, which indicates how much energy is lost per cycle in an insulation system. It is expressed as the ratio of the resistive current (loss current) to the capacitive current (displacement current). A high tan delta value signifies an increased level of energy loss, suggesting potential issues such as deterioration or moisture ingress in the insulation.

This testing technique is particularly useful for assessing various types of electrical equipment, including transformers, cables, generators, and switchgear. It helps identify insulation weaknesses before they develop into catastrophic failures, thus ensuring safety and reliability in electrical systems.

Significance of Tan Delta Test Equipment

Tan delta test equipment is critical in conducting accurate and reliable measurements. It allows engineers and maintenance personnel to evaluate the condition of insulation and to make informed decisions regarding maintenance, replacement, or further investigation. The equipment is designed to provide real-time data, which can be crucial for preventive maintenance strategies.

One of the key advantages of using tan delta test equipment is the ability to perform non-destructive testing, which eliminates the need for shutting down equipment for extensive examinations. By periodically monitoring the tan delta values, operators can detect trends that may indicate a decline in insulation condition, thus facilitating timely interventions.

Operational Principles of Tan Delta Test Equipment

The operational principles of tan delta test equipment involve several integral components. The core of the system includes a high-voltage power source, a measuring circuit, and a data acquisition system. Here’s how the process typically unfolds

1. Application of Voltage The equipment applies a defined AC voltage to the insulation under test. This voltage should match the operational conditions of the equipment being tested to ensure accurate results.

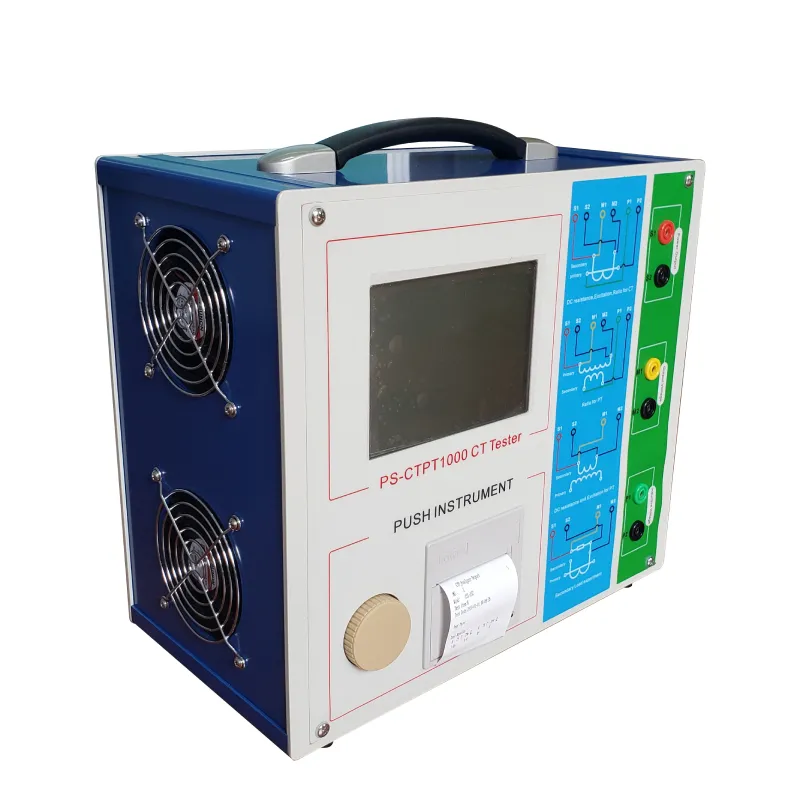

tan delta test equipment

2. Current Measurement The system measures both the resistive current (I_R) and the capacitive current (I_C) flowing through the insulation. The resistive current represents the energy loss, while the capacitive current reflects the energy stored in the field.

3. Calculating Tan Delta By using the formula tan δ = I_R / I_C, the equipment calculates the tan delta value. This number provides insight into the condition of the insulation. A tan delta value that exceeds established thresholds indicates the need for further investigation or corrective action.

4. Data Logging and Analysis Modern tan delta test equipment often includes advanced data logging capabilities, allowing for the storage and analysis of test results over time. This historical data can support trend analysis and condition monitoring, critical for long-term asset management.

Applications of Tan Delta Test Equipment

Tan delta testing is widely applicable across various industries, including

- Power Generation and Distribution In power plants, electricity transmission networks, and substations, tan delta testing helps monitor transformers, bushings, and cables, ensuring the efficiency and safety of power delivery.

- Industrial Manufacturing Many manufacturing processes rely on electric motors and generators. Regular testing ensures these components are operating efficiently without risking unexpected downtime.

- Renewable Energy With the rise of wind and solar power installations, tan delta tests are employed to maintain the reliability of their integrated electrical systems.

- Transportation In the railway and automotive sectors, ensuring the integrity of electrical systems is crucial for safety and operational efficiency.

Conclusion

Tan delta test equipment serves a vital role in maintaining the safety, efficiency, and dependability of electrical insulation systems. By understanding the principles and applications of this technology, industries can better ensure the longevity of their electrical assets. Continual advancements in testing methods and equipment further enhance the ability to monitor and maintain critical infrastructure, paving the way for a more sustainable and reliable future in electrical engineering.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025