English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

kinematic viscosity measurement

Kinematic Viscosity Measurement Principles and Techniques

Kinematic viscosity is a fundamental property of fluids that describes their internal resistance to flow under the influence of gravity. It is defined as the ratio of dynamic viscosity to fluid density, expressed in units of square meters per second (m²/s) or centistokes (cSt). Accurate measurement of kinematic viscosity is critical in various fields, including hydraulics, lubrication, and the food industry, as it influences fluid behavior in both static and dynamic conditions.

Importance of Kinematic Viscosity

Kinematic viscosity plays a vital role in determining the flow characteristics of fluids. It affects how fluids behave in pipes, how they mix with other substances, and their ability to transport materials. In engineering applications, understanding the kinematic viscosity of a lubricant is essential to ensure optimal performance in machinery. For instance, if a lubricant's viscosity is too high, it can lead to excessive resistance to flow, while a viscosity that is too low may result in inadequate lubrication, leading to increased wear and tear on mechanical components.

Methods of Measurement

Various methods are employed to measure kinematic viscosity, each with its specific applications, advantages, and limitations. The choice of method depends on factors such as the type of fluid being tested, the expected viscosity range, and the required accuracy.

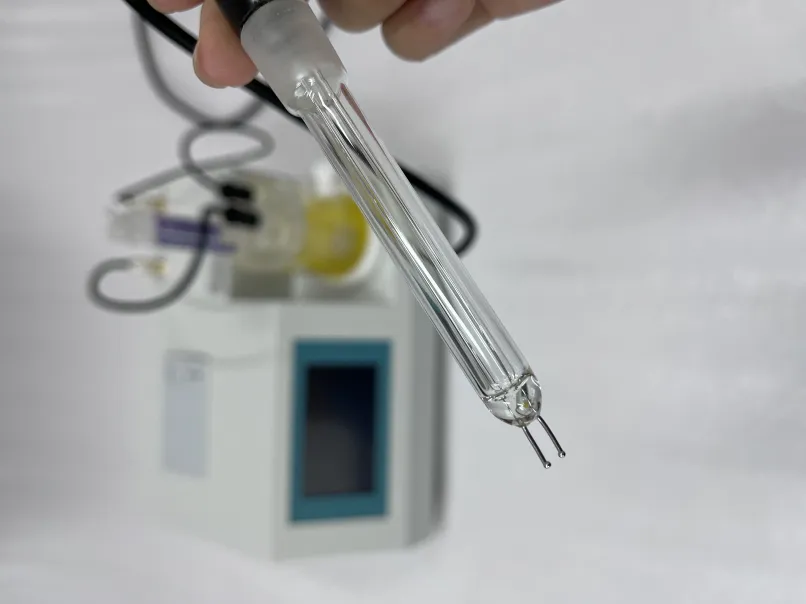

Capillary viscometers, such as the Ostwald and Ubbelohde viscometers, are commonly used for measuring the kinematic viscosity of low-viscosity fluids. These instruments consist of a small tube with a known diameter, and the time it takes for a specific volume of fluid to flow through the tube is measured. The kinematic viscosity is then calculated using the dimensions of the tube and the time measurement. This method is advantageous for its simplicity and low cost; however, it is primarily suitable for Newtonian fluids and can be affected by temperature fluctuations.

2. Rotational Viscometers

kinematic viscosity measurement

Rotational viscometers measure viscosity by applying a controlled shear stress to the fluid and observing the resulting shear rate. While these instruments primarily provide dynamic viscosity readings, kinematic viscosity can be derived if the fluid density is known. Rotational viscometers are versatile and can accommodate a wide range of fluids, including both Newtonian and non-Newtonian fluids. Their ability to measure viscosity over various shear rates makes them particularly useful in applications where the fluid's behavior under different flow conditions is critical.

3. Falling Ball Viscometers

Falling ball viscometers operate on the principle of gravity and resistance. A ball of known size and density is allowed to fall through a fluid, and the time it takes for the ball to travel a specified distance is measured. The kinematic viscosity is then calculated based on the ball's terminal velocity. This method is effective for measuring the viscosity of non-Newtonian fluids as well, but it requires careful consideration of the ball size and fluid characteristics to ensure accurate measurements.

4. Automated Viscosity Analyzers

With advancements in technology, automated viscosity analyzers have emerged, providing rapid and precise measurements of kinematic viscosity. These devices often employ multiple measurement techniques and can operate with minimal operator intervention. They are particularly beneficial in quality control settings where large volumes of fluid need to be tested quickly and reliably.

Temperature Considerations

Temperature has a significant impact on the kinematic viscosity of fluids, with most fluids experiencing a decrease in viscosity as temperature increases. Therefore, it is crucial to control the temperature during viscosity measurements and report the results at a specified reference temperature, typically 20°C or 40°C. Many viscometers are equipped with temperature control systems to maintain consistent testing conditions.

Conclusion

Kinematic viscosity measurement is essential for understanding fluid behavior in a variety of applications. By employing appropriate measurement techniques, engineers and scientists can obtain accurate viscosity values that inform design decisions, quality control processes, and safety assessments. As industries continue to advance, the development of new technologies for viscosity measurement will play a crucial role in optimizing fluid performance and ensuring efficiency across numerous applications.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025