English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Evaluating the Breakdown Strength of Transformer Oil for Improved System Reliability

Understanding Transformer Oil Breakdown Strength

Transformer oil, a crucial component in the operation of electrical transformers, serves several important functions, including insulation, cooling, and arc suppression. However, the performance and longevity of transformer oil are significantly influenced by its breakdown strength. Breakdown strength refers to the maximum voltage that a dielectric material, like transformer oil, can withstand before it becomes conductive. Understanding and maintaining the breakdown strength of transformer oil are paramount for ensuring the safe and efficient operation of transformers.

Importance of Breakdown Strength

The breakdown strength of transformer oil is a critical parameter for assessing insulation quality. A high breakdown strength indicates that the oil can effectively prevent electrical discharges. If the breakdown strength diminishes, this can lead to partial discharge or even catastrophic failures, resulting in severe economic losses and potential hazards. Effective insulation is essential in preventing short circuits and equipment damage, making breakdown strength a key metric for transformer health.

Factors Affecting Breakdown Strength

Several factors can influence the breakdown strength of transformer oil

1. Moisture Content Water is one of the most detrimental contaminants in transformer oil. Even trace amounts can significantly decrease the breakdown strength. Moisture leads to the creation of ionized paths in the oil, facilitating the initiation of electrical breakdown.

2. Temperature As the temperature of the oil increases, its viscosity decreases, which can lead to reduced breakdown strength. High temperatures can also accelerate the aging process of the oil, contributing to the breakdown of its chemical structure.

3. Contaminants Particles, metals, and other contaminants can create conductive paths that reduce the breakdown strength. Regular testing for impurities is essential to maintain oil quality.

4. Age of the Oil Over time, transformer oil undergoes oxidation and degradation, leading to a decrease in its insulation properties. The accumulation of sludge and the formation of acids can further reduce its effectiveness.

transformer oil breakdown strength

Testing Breakdown Strength

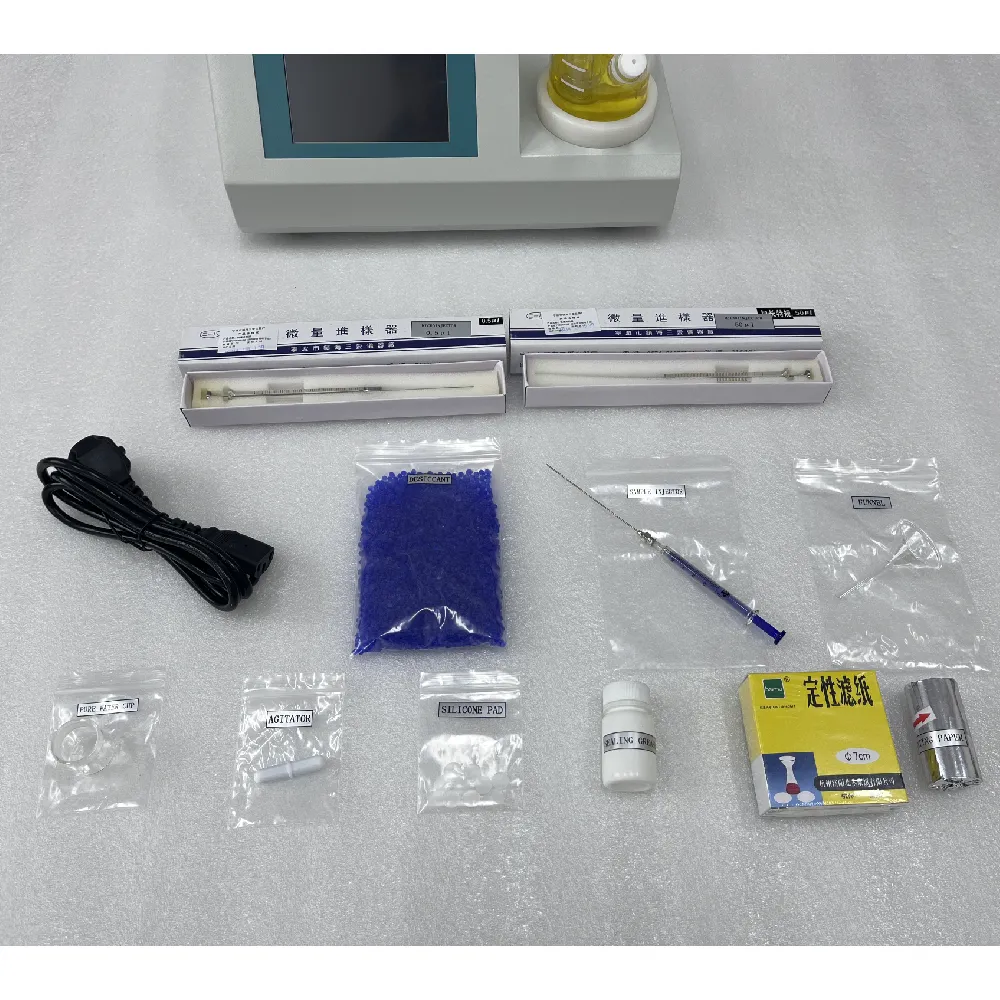

To ensure that transformer oil maintains adequate breakdown strength, it is essential to conduct regular testing. The most common testing method is the ASTM D877 test, which involves applying a voltage to a sample of oil until breakdown occurs. The voltage at which breakdown occurs is recorded as the breakdown strength of the oil.

In addition to this standard test, oil samples are also analyzed for moisture content, acidity, and the presence of particulate contaminants. These tests provide a comprehensive picture of the oil's condition and help in planning maintenance activities.

Maintenance Strategies

To maintain the breakdown strength of transformer oil, certain strategies can be employed

1. Regular Sampling and Testing Routine testing of transformer oil helps identify problems early. Laboratories can provide detailed analyses that inform maintenance schedules.

2. Dehydration Techniques such as vacuum dehydration or use of filtration systems can effectively reduce moisture levels in transformer oil, thereby improving breakdown strength.

3. Replacement In cases where the breakdown strength has significantly diminished due to aging or contamination, replacing the oil may be the most viable solution.

4. Keeping Electrical Stress Within Limits Adhering to the manufacturer's specifications regarding the electrical loading on transformers can prevent excessive stress on the oil.

Conclusion

Understanding and maintaining the breakdown strength of transformer oil is essential for the efficient and safe operation of electrical transformers. Through regular testing, preventive maintenance, and adhering to best practices, operators can ensure the longevity of transformers and minimize operational risks. As technology evolves and electrical infrastructure becomes increasingly complex, the role of high-quality transformer oil will remain a critical element in ensuring reliability and performance in power distribution networks.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025