English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Exploring BDV Test Applications in Transformer Technology and Performance Evaluation

Understanding BDV Test in Transformers

In the realm of electrical engineering, particularly in the maintenance of transformers, the BDV test, or Breakdown Voltage test, plays a crucial role in ensuring the operational integrity and longevity of transformer insulation systems. This test assesses the dielectric strength of insulating liquids used in transformers, significantly affecting the performance and reliability of electrical equipment.

Transformers are essential components in electrical power systems, serving to transfer electrical energy between two or more circuits through electromagnetic induction. However, the efficiency of a transformer is heavily reliant on its insulating materials. Over time, these insulators can degrade due to factors like moisture, contamination, and thermal stress, which can lead to electrical failures and unexpected outages. Thus, regular testing is imperative.

Understanding BDV Test in Transformers

Understanding the significance of the BDV test involves a closer look at the consequences of inadequate insulation. When breakdown occurs, it can lead to short circuits, transformer overheating, and consequently, failure of the entire electrical system. These failures not only pose safety hazards but also result in significant economic losses due to downtime and repairs. Regular BDV testing, therefore, becomes an integral part of preventative maintenance practices.

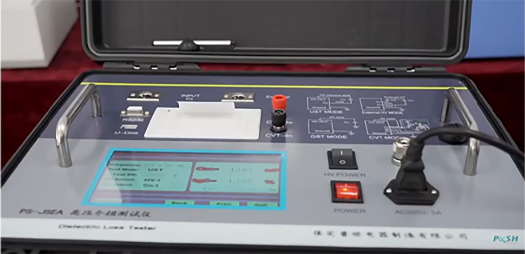

bdv test in transformer

The BDV test procedure is fairly straightforward, but it requires strict adherence to safety measures and standards. Testing should be conducted in a controlled environment, away from moisture and other contaminants. The equipment should be calibrated correctly to ensure accurate readings. Additionally, it’s essential to consult relevant standards such as ASTM D1816, which provides guidelines for testing the dielectric strength of insulating liquids.

In practice, results from the BDV test inform maintenance strategies. If the breakdown voltage is below a certain threshold, typically around 30 kV for new insulating oils, it indicates the necessity for actions such as filtration or replacement of the oil. Regular monitoring allows maintenance teams to track changes over time, helping to predict when problems might arise, thereby enabling timely interventions.

The role of technology in the BDV testing process cannot be understated. Advances in testing equipment and methods have led to more accurate and efficient BDV assessments. Automated testing devices have reduced human error and have enabled more consistent results. Furthermore, integrating these tests into condition-based monitoring systems enhances the predictive maintenance capabilities of electrical utilities, allowing for more proactive management of transformer health.

Additionally, the BDV test has applications beyond transformers; it is also relevant in assessing the condition of capacitors, voltage regulators, and other electrical components that rely on insulating fluids. By understanding the implications of dielectric breakdown across various applications, engineers can better safeguard their equipment and ensure a stable power supply.

In conclusion, the BDV test is a vital diagnostic tool in the maintenance and management of transformers. By regularly assessing the dielectric strength of insulating fluids, organizations can prolong the lifespan of their electrical assets, minimize risks of failure, and optimize operational efficiency. Given the increasing demand for reliable energy solutions, understanding and implementing robust testing measures like the BDV test is more critical than ever. In the ever-evolving landscape of electrical engineering, staying informed and prepared will allow for sustainable growth and development in energy infrastructure.

-

Ensuring SF₆ Gas Safety: Introducing PUSH’s Integrated SF₆ Analyzer for Dew Point, Purity, and Decomposition MonitoringNewsJul.10,2025

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025