English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

dielectric strength tester

Understanding Dielectric Strength Testers Ensuring Electrical Safety

In the world of electrical engineering, safety is paramount. With the increasing complexity of electrical systems, ensuring that materials can withstand high voltages without breaking down is critical. This is where dielectric strength testers come into play. These devices are essential for evaluating the insulating properties of materials, ensuring that they meet safety standards and can perform reliably in various applications.

What is Dielectric Strength?

Dielectric strength is defined as the maximum electric field that a material can withstand without experiencing failure (breakdown). It is measured in volts per unit thickness (volts per millimeter or volts per inch). When a material reaches its dielectric strength, it can no longer resist the flow of electric current, leading to potential short circuits, equipment failures, or even catastrophic accidents. Therefore, testing a material’s dielectric strength is crucial in the design and manufacturing of electrical components and systems.

The Role of Dielectric Strength Testers

Dielectric strength testers are specialized devices used to assess the insulating properties of a variety of materials, including plastics, rubber, and ceramics. By applying a high voltage across a test sample, these devices determine how much voltage the material can tolerate before breakdown occurs.

These testers come in various forms, from simple handheld units to sophisticated bench-top models equipped with advanced features. Common testing methods include

1. AC Voltage Testing This method applies alternating current (AC) voltage to the material. It is particularly useful for evaluating materials used in power applications. 2. DC Voltage Testing In this method, direct current (DC) voltage is applied. It is often used for precise measurements and is beneficial in applications where DC voltage is the operational standard.

3. Impulse Voltage Testing This technique involves applying a brief, high-voltage impulse to simulate conditions that materials may encounter in real-world situations.

Importance of Testing

Conducting dielectric strength testing is crucial for several reasons

1. Safety Assurance The primary goal of dielectric strength testing is to ensure the safety of electrical systems. By identifying materials that cannot withstand required voltage levels, manufacturers can prevent the use of unsafe materials in their products.

2. Quality Control Manufacturers employ dielectric strength testers as part of their quality control processes. Consistent testing ensures that products manufactured at different times meet the same safety standards.

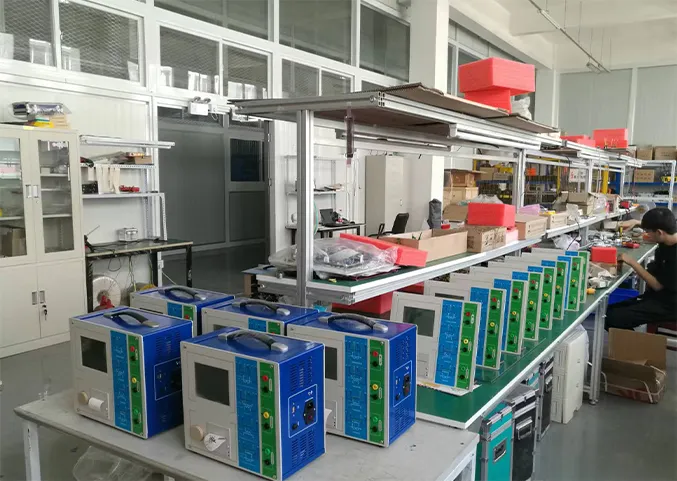

dielectric strength tester

3. Regulatory Compliance Many industries are mandated to adhere to specific safety standards and regulations. Performing dielectric strength tests helps organizations comply with local and international safety guidelines, thereby mitigating legal liabilities.

4. Material Selection Engineers often rely on dielectric strength as a key factor when selecting materials for electrical applications. Understanding the dielectric properties of materials aids in choosing suitable insulators for specific environments.

5. Preventing Equipment Failure Regular testing can identify potential failure points in electrical components before they become critical, thus allowing for proactive maintenance and replacement strategies.

How to Choose a Dielectric Strength Tester

When selecting a dielectric strength tester, consider the following factors

- Voltage Range Ensure the tester can accommodate the voltage levels you intend to measure. Testers come equipped to handle low, medium, and high voltages depending on the application.

- Testing Method Decide between AC, DC, or impulse testing based on your specific needs.

- User-Friendliness Evaluate the interface and ease of use, especially if the tester will be used by multiple operators.

- Calibration and Accuracy Look for models that offer easy calibration and have a reputation for reliability and precision.

- Portability If testing will occur in various locations, consider a portable model with a robust design.

Conclusion

Dielectric strength testers are vital tools for ensuring the safety and reliability of electrical components and systems. By assessing the insulating properties of materials under high voltage conditions, these devices play a crucial role in preventing electrical failures and ensuring compliance with safety standards. Understanding their function and significance helps engineers and manufacturers select the right materials and testing methods, ultimately contributing to safer electrical applications across industries. As technology continues to evolve, so too will the capabilities of dielectric strength testers, making them an indispensable part of electrical engineering.

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025