English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

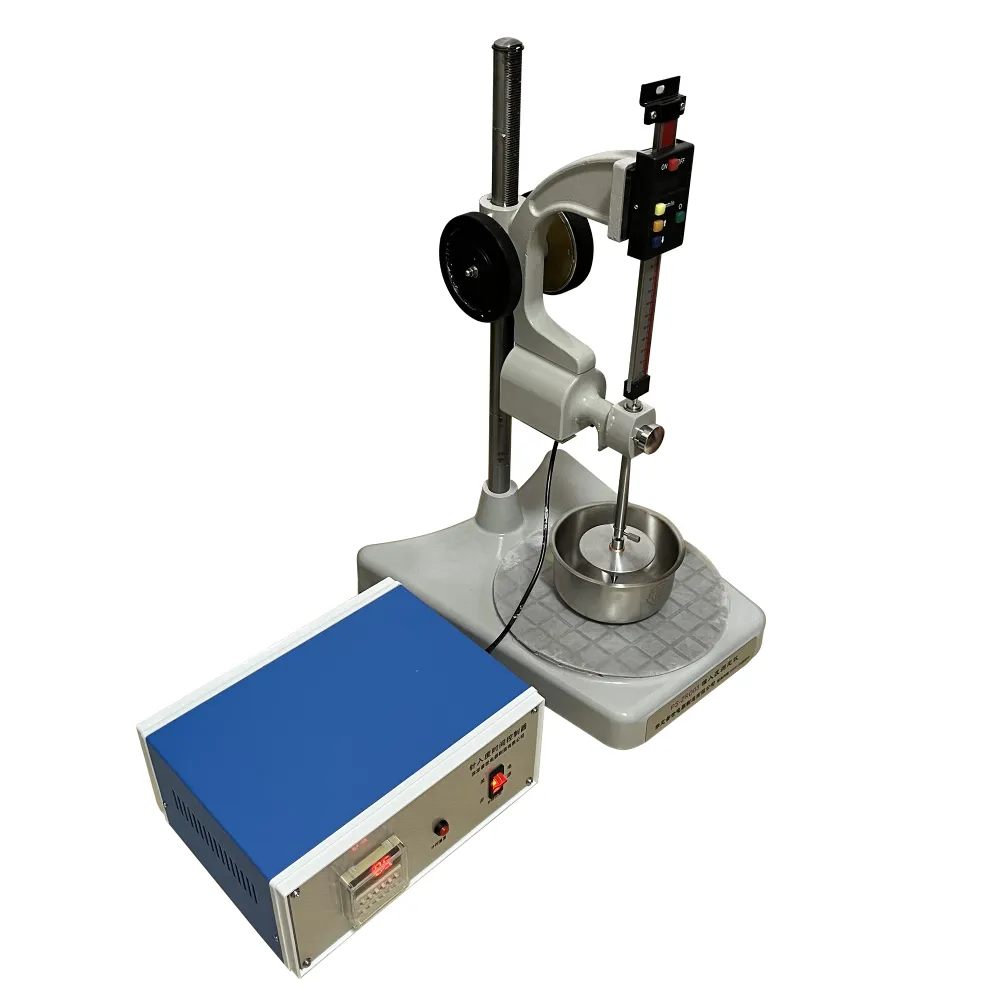

oil analysis equipment

Oil analysis equipment plays a pivotal role in maintaining the operational efficiency and longevity of machinery across various industries, from automotive to industrial manufacturing. As modern businesses strive to optimize resource utilization and minimize downtimes, understanding the intricacies of oil analysis has never been more crucial. The equipment used in oil analysis is designed to detect contaminants, monitor lubricant conditions, and predict equipment failures, making it an indispensable tool for businesses aiming to maintain peak performance.

Experience has shown that investing in high-quality oil analysis equipment can lead directly to improved machinery health and cost savings. Operators and maintenance teams who've incorporated oil analysis into their routine maintenance practices report reductions in unscheduled downtimes and maintenance costs. This is not merely anecdotal; companies have documented significant improvements in equipment longevity and reliability when regular oil checks are conducted using advanced analysis machinery. By identifying potential issues early, businesses can prevent minor problems from escalating into major failures, thus protecting their investment and ensuring continuous operation.

From an expertise perspective, the sophistication of modern oil analysis equipment cannot be understated. These tools employ a variety of techniques, such as spectroscopy, particle counting, and viscosity measurement, to assess the condition of the oil and, by extension, the machinery. Each of these methods provides insights into different parameters of lubricant health and potential contamination. For instance, spectroscopy helps in determining metal content in oil, which is crucial for predicting and avoiding wear-related failures. Therefore, possessing the technical know-how to select and operate these devices effectively is essential for achieving accurate diagnostics.

When discussing authoritativeness, it’s important to highlight the brands and manufacturers that lead the field in oil analysis technology. Companies like Spectro Scientific, a division of AMETEK, and Parker Hannifin offer state-of-the-art equipment recognized globally for their precision and reliability. Their solutions are developed by industry experts with decades of experience in lubrication science and oil analysis techniques. Their innovative products set the standard for what is possible in terms of diagnostic accuracy and ease of use, providing authoritative solutions to meet even the most demanding industrial needs.

Trustworthiness in oil analysis equipment derives not only from the quality of the devices but also from the support and validation that users receive. Leading manufacturers often provide extensive training, certification programs, and continued support for their clients, ensuring that the machinery is used to its fullest potential. Furthermore, independent certifications and adherence to international standards, such as ISO 9001, offer an additional layer of trust, guaranteeing that the equipment meets rigorous quality and performance criteria.

In conclusion, oil analysis equipment is an essential investment for any organization relying on machinery for its operations. By leveraging experience, expertise, authority, and trustworthiness, businesses can significantly enhance their maintenance processes, reduce operational risks, and extend the lifespan of their equipment. Whether adopting oil analysis for the first time or upgrading existing capabilities, the selection of proven, reliable equipment is vital to maximizing the return on investment and ensuring operational continuity.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025