English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

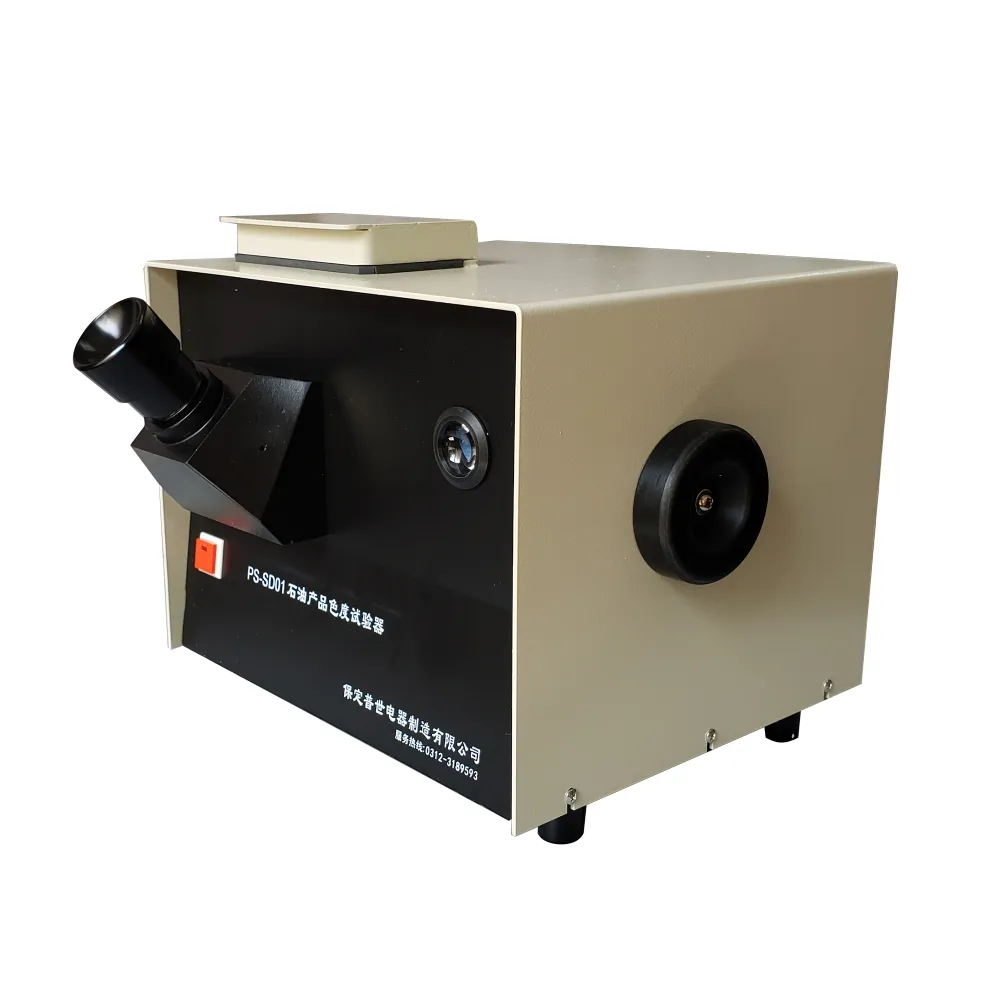

insulating oil tester

Understanding the Importance of Insulating Oil Testers in Electrical Systems

Insulating oil testers are essential instruments used in the maintenance and assessment of electrical equipment, particularly transformers and circuit breakers. These oils play a crucial role in the operational efficiency and safety of electrical systems, acting as both an insulator and a coolant. As such, monitoring the quality of insulating oil is vital for ensuring the longevity and reliability of electrical infrastructures.

What is Insulating Oil?

Insulating oil, typically a type of mineral oil, is employed in various electrical apparatuses due to its excellent dielectric properties. It provides insulation between conductive components, preventing short circuits and electrical failures. Additionally, it helps dissipate heat generated during the operation of electrical devices, maintaining optimal performance levels. Over time, however, the insulating properties of oil can degrade due to exposure to parameters such as moisture, temperature, and chemical contaminants.

The Role of Insulating Oil Testers

Insulating oil testers serve as diagnostic tools to evaluate the quality and performance of insulating oils. These devices can measure several critical properties of the oil, offering insights into its condition and suitability for continued use. Some of the key parameters assessed include

1. Dielectric Strength This measures the voltage at which the oil fails to insulate, indicating how much further voltage can be applied before a breakdown occurs. A higher dielectric strength signifies better insulation performance.

2. Moisture Content Water contamination in insulating oil can significantly reduce its dielectric strength. Oil testers quantify moisture levels, helping to determine whether the oil needs purification or replacement.

3. Acid Number Over time, insulating oils can oxidize, leading to the formation of acidic compounds. The acid number provides insight into the degree of oil degradation, informing maintenance decisions and scheduling.

4. Furan Analysis By-products of cellulose deterioration can be identified with furan analysis, which gives indications of insulation breakdown in transformers. Regular testing can help predict failures before they occur.

5. Polychlorinated Biphenyls (PCBs) Older insulating oils may contain harmful chemicals known as PCBs, which are now banned in many regions due to their environmental and health hazards. Insulating oil testers can detect these compounds, ensuring compliance with regulations.

Benefits of Regular Testing

Regular testing of insulating oils using dedicated testers can significantly enhance the management of electrical assets

. Some of the major benefits includeinsulating oil tester

- Preventive Maintenance By identifying potential problems before they escalate, organizations can adopt a proactive maintenance approach, reducing the likelihood of costly failures and unscheduled downtimes.

- Extended Equipment Lifespan Consistent monitoring ensures that insulating oils remain within desirable quality thresholds, prolonging the life of electrical equipment.

- Safety Assurance Maintaining the integrity of insulating oils helps mitigate risks associated with electrical failures, contributing to the safety of both personnel and equipment.

- Cost Efficiency Anticipating and addressing issues ahead of time can lead to significant cost savings associated with repairs, replacements, and lost production.

Choosing the Right Insulating Oil Tester

When selecting an insulating oil tester, several factors should be considered

- Accuracy and Reliability Ensure the tester you choose provides consistent and precise measurements across all parameters evaluated.

- Ease of Use Opt for models with user-friendly interfaces, clear displays, and straightforward operational protocols.

- Portability Portable testers allow for on-site assessments, making it easier to conduct routine checks without transporting large samples to a lab.

- Regulatory Compliance Ensure that the tester complies with relevant industry standards and regulations for testing insulating oils.

Conclusion

Insulating oil testers are indispensable tools in the electrical industry. By continuously monitoring the quality of insulating oils, companies can safeguard their electrical infrastructure, optimize equipment performance, and ensure compliance with safety regulations. Investing in reliable testing equipment is not just a maintenance strategy; it is a critical investment in the future reliability and safety of electrical systems. As technologies evolve, integrating advanced testing solutions will further enhance the efficiency and sustainability of electrical operations worldwide.

-

Using Distillation Range Testers in the Food and Beverage IndustryNewsApr.16,2025

-

The Impact of IoT on Distillation Range Tester PerformanceNewsApr.16,2025

-

The Best Distillation Range Testers for Extreme ConditionsNewsApr.16,2025

-

How Distillation Range Testers Save Time and MoneyNewsApr.16,2025

-

Distillation Devices for Advanced Separation TechniquesNewsApr.16,2025

-

Common Mistakes to Avoid When Using a Distillation Range TesterNewsApr.16,2025