English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

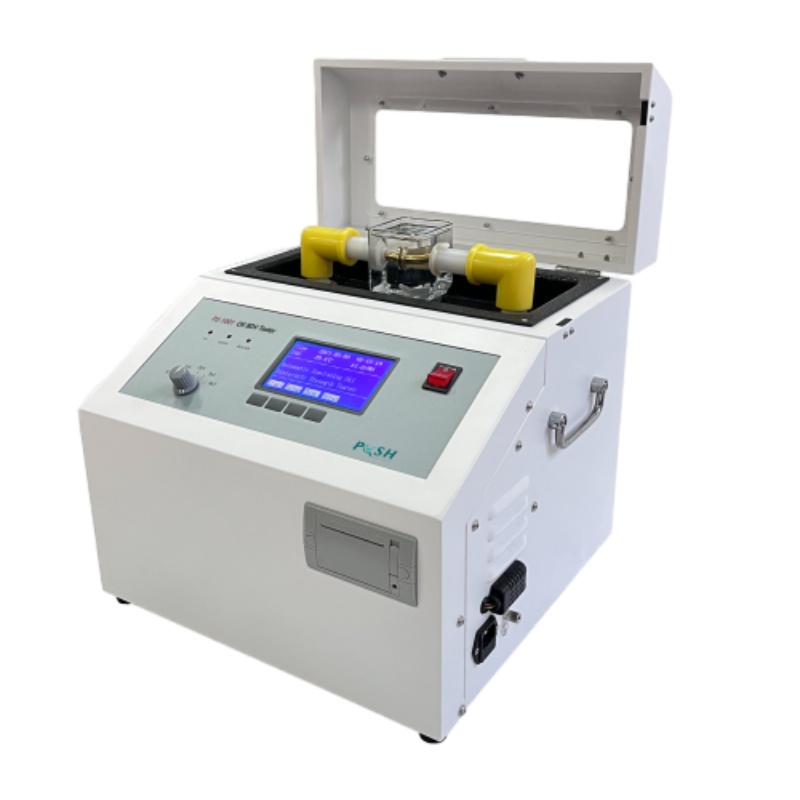

oil breakdown test

Understanding the Oil Breakdown Test A Key to Ensuring Engine Longevity

The oil breakdown test, often regarded as a critical evaluation in automotive and machinery maintenance, stands as a cornerstone in ensuring the longevity and efficiency of engines. As our vehicles and machinery become increasingly sophisticated, the requirement for regular diagnostics becomes paramount. This article will explore the intricacies of the oil breakdown test, its significance, and how it contributes to the overall health of engine systems.

What is the Oil Breakdown Test?

The oil breakdown test is designed to measure the degradation of lubricating oil under operational conditions. Lubricating oil is pivotal to the functioning of an engine; it reduces friction among moving parts, cools engine components, and prevents corrosion. As oil circulates, it undergoes various changes due to heat, pressure, and contamination. The breakdown test assesses how effectively the oil can continue to perform its duties before it becomes unsuitable for use.

The Importance of Regular Testing

Regular oil breakdown tests can prevent premature engine wear and failure. Over time, contaminants such as dirt, fuel, and water can accumulate in the oil, leading to decreased performance. Additionally, the additives in the oil that help maintain its properties may become depleted. By conducting regular tests, operators can make informed decisions about oil changes and avoid costly repairs associated with engine damage.

The Testing Process

The oil breakdown test typically involves sampling the oil during regular maintenance intervals. Laboratory testing analyzes various parameters, including viscosity, acidity (measured as Total Acid Number or TAN), presence of metals, and other contaminants.

1. Viscosity Testing This assesses the oil's thickness and its ability to create a lubricating film. Oils that have thinned out can no longer provide adequate protection. 2. Total Acid Number (TAN) This measures the acidity level of the oil. A high TAN indicates that the oil is breaking down and can lead to corrosion of engine components. 3. Contaminant Analysis The presence of metals and other particulates can indicate wear within the engine. For example, high levels of iron might suggest wear in iron-based components.

oil breakdown test

4. Oxidation Stability This measures the oil's ability to withstand oxidation at high temperatures, which is crucial in preventing sludge formation.

Interpreting Test Results

After the analysis, the results provide valuable insights into the condition of the oil and, by extension, the engine. A significant increase in acidity or changes in viscosity may indicate that the oil needs to be changed sooner rather than later. Moreover, a high concentration of wear metals signals a potential problem with specific engine components, necessitating further investigation.

Taking Action Based on Results

Understanding the implications of the oil breakdown test results is essential for maintenance planning. If the test suggests that the oil has significantly degraded, it indicates a need for immediate oil change, which should include a thorough inspection of the affected engine parts. Furthermore, if contaminants are found, it may lead to necessary repairs or modifications in the maintenance routine to prevent recurrence.

Conclusion Maximizing Engine Performance

The oil breakdown test is not merely a routine procedure; it is a proactive approach to maintaining engine health and performance. By frequently monitoring oil condition, operators can extend the lifespan of their engines, boost performance, and reduce fuel consumption. In an era where every drop of fuel and every minute of operation matters, incorporating oil breakdown tests into regular maintenance schedules is a smart move for any vehicle owner or machinery operator.

In essence, understanding and utilizing the oil breakdown test reflects a commitment to mechanical integrity, efficiency, and ultimately, cost savings. As technology progresses and engines become more demanding, the importance of this test will only increase, solidifying it as an undeniable component of effective mechanical maintenance.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025