English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

pat testing 12v transformers

Understanding PAT Testing for 12V Transformers

In an era where electrical equipment is ubiquitous, ensuring the safety and reliability of such devices is paramount. Among the tools used for testing electrical safety is Portable Appliance Testing (PAT), which is especially critical for devices operating at lower voltages, such as 12V transformers. This article explores the nuances of PAT testing specifically in the context of 12V transformers, discussing its significance, methodology, and best practices.

What is PAT Testing?

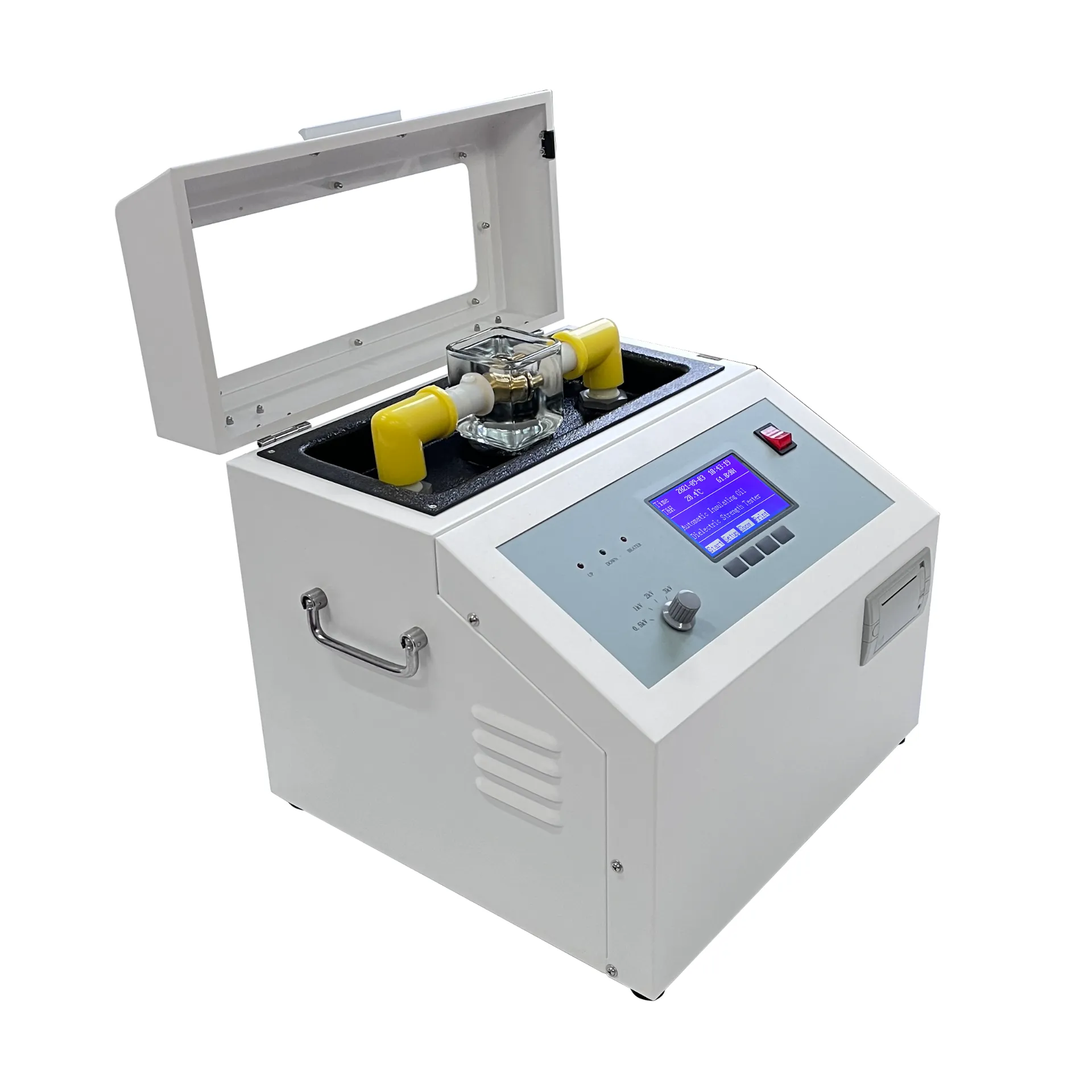

Portable Appliance Testing (PAT) is a systematic process that involves testing electrical appliances to ensure they are safe for use. The procedure typically covers visual inspections and electrical tests to identify any potential hazards. For 12V transformers, which are often used in a variety of applications from powering LED lights to charging batteries, PAT testing is essential to verify that these devices are functioning properly and are safe to operate.

Importance of PAT Testing for 12V Transformers

The primary purpose of PAT testing is to prevent electrical accidents that can lead to injuries, fires, or equipment damage. For 12V transformers, this is particularly important due to their use in various environments where they may come into contact with moisture or mechanical stresses. Regular PAT testing ensures that these transformers maintain their integrity and complies with safety regulations. Additionally, carrying out PAT testing can enhance equipment lifespan, minimize downtime, and bolster compliance with industry standards.

The PAT Testing Process

When conducting PAT testing on 12V transformers, the process generally includes the following steps

1. Visual Inspection The first step involves a thorough examination of the transformer for any visible defects. This includes checking for damaged casings, frayed wires, and signs of overheating. Inspectors should also assess the plug and the power cord for any faults.

2. Earth Continuity Testing For transformers with a metal casing, this test checks the integrity of the earth connection. A low resistance reading indicates a good earth, which is essential for safe operation and effective fault protection.

3. Insulation Resistance Testing This test evaluates the insulation quality of the transformer. A high insulation resistance indicates that there is no potential leakage current, ensuring that the device is safe for use.

pat testing 12v transformers

4. Functional Testing This involves powering the device and checking if it operates within its specified parameters. For a 12V transformer, this would include measuring the output voltage to confirm it is at the required 12 volts.

5. Record Keeping After testing, it is vital to keep detailed records. This documentation serves as proof of compliance with safety regulations and can be invaluable during safety inspections or audits.

Best Practices for PAT Testing

To optimize PAT testing for 12V transformers, consider the following best practices

- Regular Testing Schedule Establish a routine PAT testing schedule based on usage and environment. Devices used in high-risk environments or frequently may require more frequent checks.

- Trained Personnel Ensure that only trained and qualified personnel conduct the testing, as their expertise will reduce errors and enhance safety.

- Stay Updated with Regulations Familiarize yourself with the latest regulations concerning electrical safety to ensure compliance and protect users.

- Quality Equipment Invest in reliable and accurate PAT testing equipment to obtain consistent and precise readings.

Conclusion

PAT testing for 12V transformers serves a crucial role in maintaining safety and reliability in electrical systems. By following a systematic testing process and adhering to best practices, organizations can mitigate risks associated with electrical appliances and protect both users and assets effectively. Implementing regular PAT checks not only fosters a culture of safety but also ensures that equipment operates efficiently and remains in good working order.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025