English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

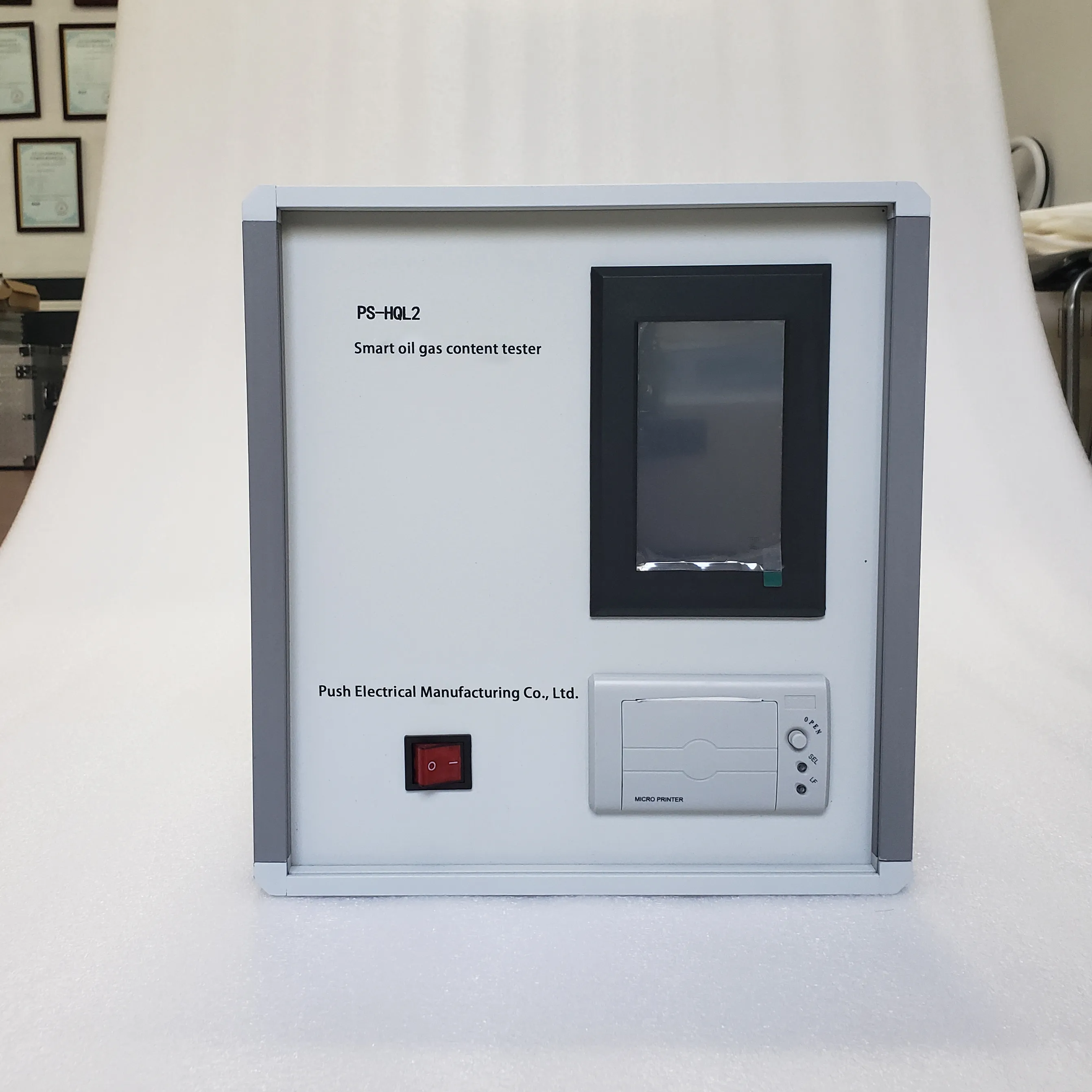

insulation oil testing

Insulation Oil Testing Ensuring Electrical System Reliability

Insulation oil, also known as transformer oil, is a crucial component in electrical equipment, particularly in transformers and capacitors. This specialized oil serves two primary purposes it acts as an electrical insulator and helps dissipate heat. Over time, however, insulation oil can degrade due to exposure to environmental factors, electrical stresses, and thermal influences. To ensure the reliability and efficiency of electrical systems, regular insulation oil testing is imperative.

The Importance of Insulation Oil Testing

Testing insulation oil is critical for several reasons

1. Prevent Equipment Failure The most significant risk associated with degraded insulation oil is the potential for equipment failure. Transformers are essential components of electrical distribution systems; any failure can lead to costly outages and damage. Regular testing helps detect early signs of deterioration, allowing for timely maintenance or replacement.

2. Safety Degraded insulation oil can pose fire risks. In high-voltage systems, the ability of the oil to effectively insulate is vital. By conducting routine tests, the likelihood of accidents due to electrical faults can be minimized.

3. Regulatory Compliance Many industries are required to adhere to specific safety and performance standards. Regular insulation oil testing not only ensures compliance with these regulations but also enhances the credibility and reliability of the organization that operates the equipment.

4. Cost Efficiency Addressing insulation oil issues before they escalate into larger problems can save significant costs related to repairs or replacements. Testing allows organizations to budget for maintenance and avoid unexpected expenses.

Common Tests for Insulation Oil

insulation oil testing

Several tests are routinely performed to assess the quality of insulation oil

1. Dielectric Strength Test This test measures the voltage at which the oil becomes conductive. A higher dielectric strength indicates better insulating properties. As the oil ages or becomes contaminated, its dielectric strength diminishes, leading to an increased risk of electrical failures.

2. Dissolved Gas Analysis (DGA) This test analyzes the gases dissolved in the oil. The presence of specific gases, such as hydrogen, methane, and ethylene, can indicate different types of electrical faults or overheating conditions. Tracking these gas levels over time can provide valuable insights into the health of the transformer.

3. Water Content Test Excessive water in insulation oil can severely degrade its performance. This test quantifies the moisture content, with results indicating whether the oil needs treatment or replacement.

4. Acidity Test The acidity of insulation oil increases over time, primarily due to oxidation products. High acidity levels can corrode metal components and compromise the oil's insulating properties. Regular monitoring of acidity can alert operators to potential issues.

5. Furan Analysis Furan compounds form during the degradation of cellulose insulation. By measuring furan levels in oil, it is possible to evaluate the condition of the solid insulation within transformers and predict potential failures.

Conclusion

In the realm of electrical engineering, the significance of insulation oil cannot be overstated. As the backbone of transformer safety and efficiency, ensuring the quality of insulation oil through comprehensive testing is vital. Regular inspections not only help in maintaining equipment reliability but also safeguard personnel and assets against potential hazards.

Organizations must prioritize insulation oil testing as part of their routine maintenance schedules. By investing in proper testing protocols and employing qualified technicians to conduct these tests, they can avoid unforeseen failures, it improves operational efficiency and ensures compliance with industry standards. In a rapidly evolving energy landscape, maintaining the integrity of electrical systems through effective insulation oil management is more critical than ever.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025