English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

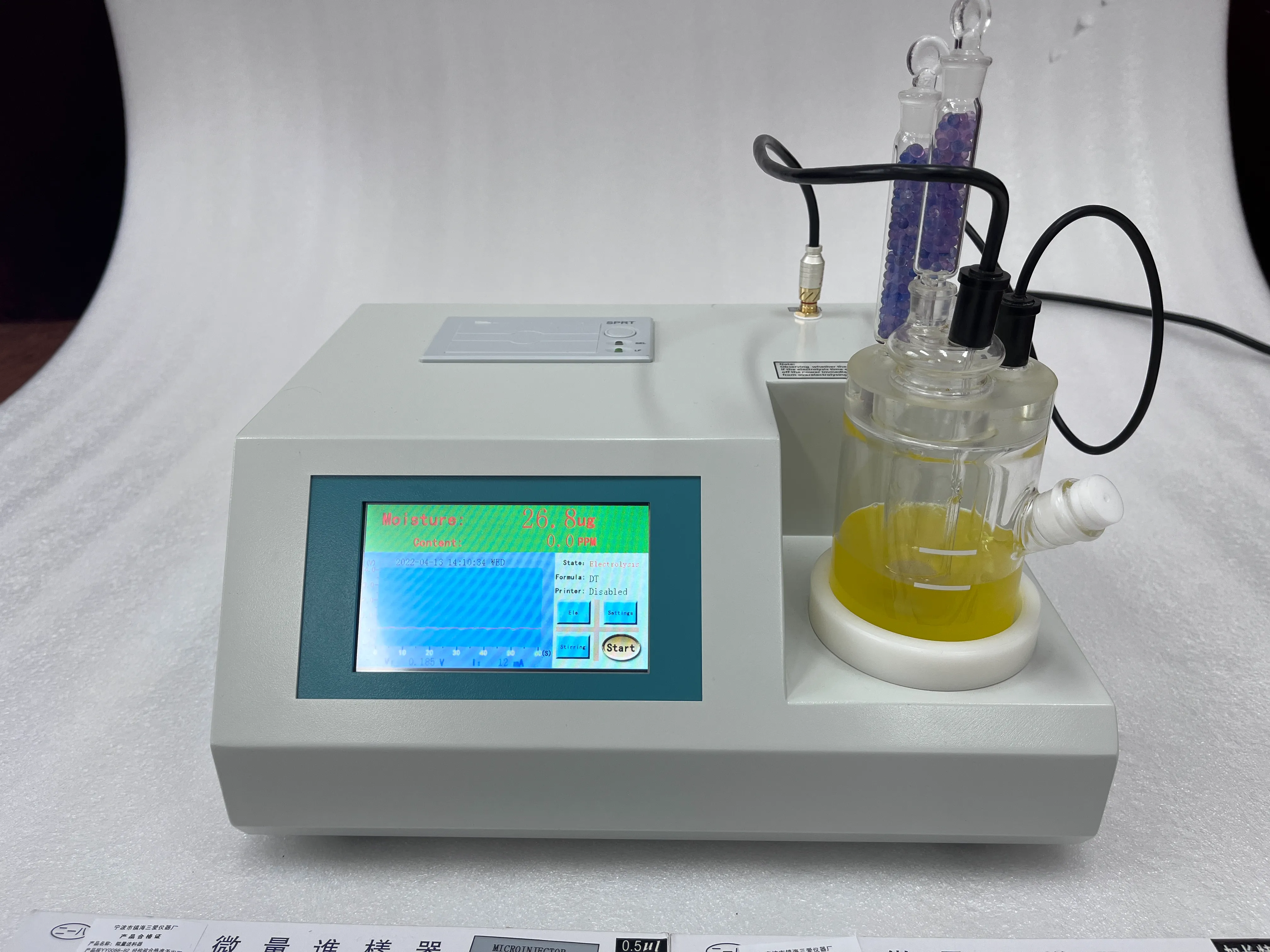

oil leakage test of transformer

Oil Leakage Test of Transformers Importance and Methodology

Transformers are a crucial component in the electrical power distribution system, serving to step up or step down voltage levels while ensuring minimal energy loss. One of the significant challenges associated with transformers is oil leakage, which can severely affect their performance and safety. Consequently, conducting oil leakage tests is vital for the effective maintenance and operation of transformers.

Understanding Transformer Oil

Transformers are filled with mineral oil, which serves as both an insulator and a coolant. This insulating oil not only prevents electrical arcing but also helps in dissipating the heat generated during the operation of the transformer. Due to variables like temperature fluctuations, mechanical stress, and aging, the integrity of transformers can be compromised, leading to oil leaks. Such leaks can result in environmental hazards and have severe implications for the reliability and safety of the electrical system.

Importance of Oil Leakage Testing

Routine oil leakage testing is critical for several reasons

1. Safety Oil leaks can pose a fire hazard, especially in areas with combustible materials. Identifying leaks early can prevent potential disasters.

2. Environmental Protection Transformer oil contains harmful chemicals that can be detrimental to the environment. Preventing leaks and accurately detecting them helps protect ecosystems.

3. Equipment Reliability A transformer with compromised oil levels may overheat or fail to operate efficiently. Leakage testing ensures that transformers are running optimally, reducing unexpected downtimes.

4. Regulatory Compliance Many regions have strict regulations regarding the monitoring and maintenance of transformers. Regular leakage testing can assist in compliance with these regulations.

5. Cost Efficiency Detecting and addressing leaks promptly can result in significant cost savings by avoiding extensive repairs or replacement of the transformer.

oil leakage test of transformer

Methodology of Oil Leakage Testing

The process of oil leakage testing typically involves several steps

1. Visual Inspection The first step in the testing process is a thorough visual examination of the transformer. Technicians look for any visible signs of oil seepage around the joints, gaskets, and seals.

2. Pressure Testing This method is commonly used to assess the integrity of the transformer’s casing. The transformer is subjected to a controlled increase in pressure. If the pressure drops significantly, it indicates a potential leak.

3. Vacuum Testing Similar to pressure testing, this method involves creating a vacuum inside the transformer. If air enters the system, it suggests that there are leaks present.

4. Dye Penetrant Testing This method involves applying a dye to the external surface of the transformer. If there is a breach, the dye will appear on the inside or outside, indicating the location of the leak.

5. Ultrasonic Testing This advanced technique uses ultrasonic waves to detect leaks. Any escaping gas from the transformer will produce a unique sound frequency that can be identified with proper equipment.

6. Environmental Monitoring Continuous monitoring of the area surrounding the transformer can be a proactive approach. Sensors can detect oil presence in the surrounding soil or water sources, indicating a leakage event.

Conclusion

The oil leakage test of transformers is an indispensable practice that ensures both operational integrity and environmental safety. As electrical grids evolve and the demand for reliable power grows, rigorous testing standards will become increasingly important. By implementing thorough oil leakage testing methodologies, utilities can protect their investments, ensure compliance with safety regulations, and contribute to sustainable practices in energy management. Regular assessment and prompt attention to any signs of oil leakage is not merely a preventative measure; it is an essential aspect of modern transformer maintenance that safeguards both people and the environment.

-

Using Distillation Range Testers in the Food and Beverage IndustryNewsApr.16,2025

-

The Impact of IoT on Distillation Range Tester PerformanceNewsApr.16,2025

-

The Best Distillation Range Testers for Extreme ConditionsNewsApr.16,2025

-

How Distillation Range Testers Save Time and MoneyNewsApr.16,2025

-

Distillation Devices for Advanced Separation TechniquesNewsApr.16,2025

-

Common Mistakes to Avoid When Using a Distillation Range TesterNewsApr.16,2025