English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

interfacial rheometer

Understanding Interfacial Rheometers A Key Tool in Material Science

Interfacial rheometers are specialized instruments designed to measure the mechanical properties of materials at interfaces, particularly in liquid-liquid and liquid-solid systems. They play a crucial role in various fields, including material science, food technology, pharmaceuticals, and even cosmetic formulation. The significance of understanding interfacial properties cannot be overstated, as they influence stability, texture, and overall quality of products in these industries.

The principle of interfacial rheometry is rooted in the study of how materials behave under stress and strain at interfaces. At its core, a rheometer measures flow and deformation of materials, providing insights into viscous and elastic properties. It's particularly important for understanding how different phases interact, which is essential for developing stable emulsions, foams, and other complex mixtures.

One of the main challenges faced in measuring interfacial properties is the complexity of the interface itself. Interfaces are often dynamic and influenced by various factors including temperature, concentration, and shear rates. Interfacial rheometers are designed to cope with these complexities by employing advanced measurement techniques. For instance, they can characterize the stress response of an interface when subjected to different flow conditions, allowing researchers to analyze the interfacial viscosity and elasticity.

There are several types of interfacial rheometers, each tailored for specific applications. The most common types include the pendant drop method, the Wilhelmy plate method, and the drop shape analysis method. Each technique has its strengths and weaknesses, and the choice of method often depends on the specific characteristics of the materials being studied and the desired information.

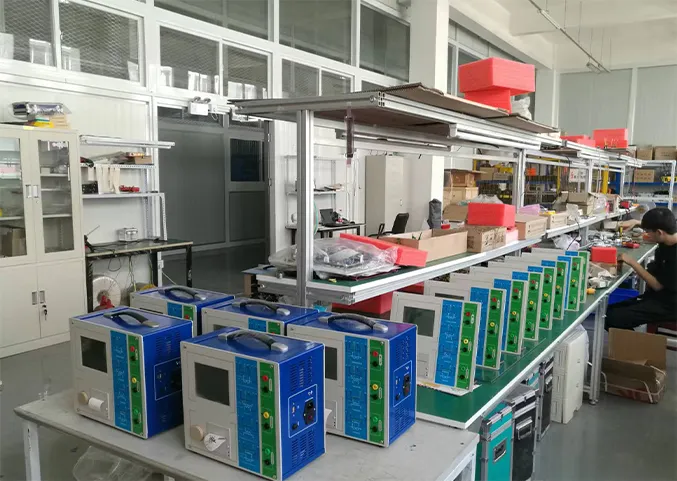

interfacial rheometer

In food technology, interfacial rheometers are essential for creating stable emulsions, which are prevalent in products like mayonnaise and salad dressings. The interfacial tension between oil and water phases plays a vital role in the emulsion's stability. By measuring interfacial rheology, food scientists can optimize formulations to achieve the desired texture and mouthfeel while preventing separation over time.

In pharmaceutical applications, interfacial rheology is critical for drug delivery systems, particularly in the design of formulations that require controlled release. Understanding how drugs interact at the interface of carriers is essential for enhancing bioavailability and ensuring efficacy. Interfacial rheometers provide the data necessary to refine these formulations, tailoring them for specific therapeutic outcomes.

The cosmetic industry also benefits from interfacial rheometry, especially in the formulation of creams and lotions. The feel and spreadability of a product are greatly influenced by its interfacial properties. By optimizing these parameters, formulators can create products that not only provide skincare benefits but also enhance consumer experience.

Despite the advantages of interfacial rheometers, challenges remain in their use. One significant issue is the ability to replicate real-world conditions within the laboratory setting. Interfaces are often influenced by environmental factors, and maintaining these conditions during testing can be difficult. Researchers are continually working to develop more sophisticated systems that can simulate real-world interactions more accurately.

In conclusion, interfacial rheometers are invaluable tools in material science and related fields. They provide essential insights into the mechanics of interfaces, helping scientists and engineers to optimize formulations across various applications. As technology continues to evolve, we can anticipate further advancements in interfacial rheometry, leading to even greater understandings of material interactions and enhanced product development. Whether in food, pharmaceuticals, or cosmetics, mastering interfacial properties will remain a critical component of innovation in the years to come.

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025