TEL:

+86-0312-3189593

English

English

Telephone:0312-3189593

Email:sales@oil-tester.com

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

ਫਰ. . 16, 2025 10:53

Back to list

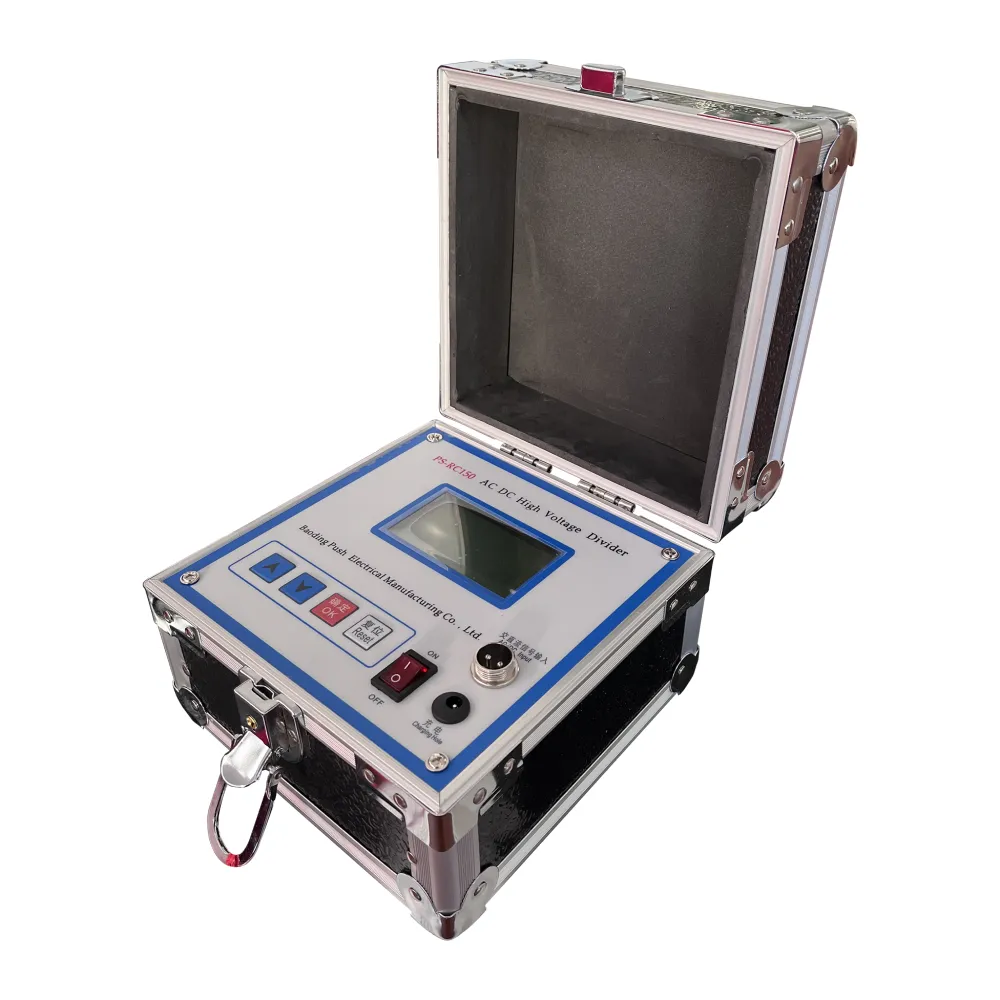

PS-JSB01 Transformer Dielectric Loss Analysis Tan Delta Tester

Tan Delta testing, an essential procedure for generators, specifically focuses on diagnosing insulation health. The test, commonly referred to as a dissipation factor or loss angle test, quantifies the dielectric losses in the insulation material between electrical conductive components under alternating current (AC) voltage conditions. Insights from this test help prevent costly generator failures and unplanned downtimes, making it a crucial step in predictive maintenance strategies for industrial setups and power plants.

In terms of authoritativeness, industry standards such as IEEE 286-2000 provide comprehensive guidelines for conducting Tan Delta tests. These standards dictate the appropriate conditions, instrumentation, and interpretation necessary for accurate assessments. Such authoritative backing reinforces the credibility of Tan Delta testing in generator maintenance protocols. Companies employing these standardized procedures reassure stakeholders that their operational strategies are deeply rooted in globally recognized practices, thereby enhancing their operational credibility. Trustworthiness in Tan Delta testing is cemented by its widespread acceptance and adoption across diverse industries including power generation, manufacturing, and even renewable energy sectors. The data derived from these tests is empirical, offering an unbiased view of insulation conditions. Trusted by engineers and facility managers alike, Tan Delta measurements drive maintenance decisions that support both safety and efficiency benchmarks, essential qualities in high-stakes operational environments. In conclusion, a Tan Delta test is more than just a diagnostic tool; it is a key component in the maintenance and reliability management of generators. Through experience-driven insights, expert application, adherence to authoritative standards, and trustworthy results, businesses can safeguard their assets and minimize downtime. This test not only supports operational resilience but also propels forward-thinking maintenance programs that capitalize on early detection and continual condition monitoring. Whether your enterprise is deeply entrenched in heavy industry or part of the burgeoning renewable sector, embedding Tan Delta testing into your maintenance regimen signifies a proactive step towards sustained operational excellence.

In terms of authoritativeness, industry standards such as IEEE 286-2000 provide comprehensive guidelines for conducting Tan Delta tests. These standards dictate the appropriate conditions, instrumentation, and interpretation necessary for accurate assessments. Such authoritative backing reinforces the credibility of Tan Delta testing in generator maintenance protocols. Companies employing these standardized procedures reassure stakeholders that their operational strategies are deeply rooted in globally recognized practices, thereby enhancing their operational credibility. Trustworthiness in Tan Delta testing is cemented by its widespread acceptance and adoption across diverse industries including power generation, manufacturing, and even renewable energy sectors. The data derived from these tests is empirical, offering an unbiased view of insulation conditions. Trusted by engineers and facility managers alike, Tan Delta measurements drive maintenance decisions that support both safety and efficiency benchmarks, essential qualities in high-stakes operational environments. In conclusion, a Tan Delta test is more than just a diagnostic tool; it is a key component in the maintenance and reliability management of generators. Through experience-driven insights, expert application, adherence to authoritative standards, and trustworthy results, businesses can safeguard their assets and minimize downtime. This test not only supports operational resilience but also propels forward-thinking maintenance programs that capitalize on early detection and continual condition monitoring. Whether your enterprise is deeply entrenched in heavy industry or part of the burgeoning renewable sector, embedding Tan Delta testing into your maintenance regimen signifies a proactive step towards sustained operational excellence.

Latest news

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025