English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Testing Methods for Different Types of Power Transformers in Electrical Engineering

Understanding Power Transformer Type Tests A Comprehensive Overview

Power transformers are critical components in electrical power systems, playing a vital role in the transmission and distribution of electrical energy. Their design, construction, and operational reliability significantly impact the efficiency of power networks. As such, it is essential to ensure that transformers operate effectively and safely. This is achieved through a series of tests known as type tests, which help to assess the transformer’s performance and compliance with specified standards.

What are Type Tests?

Type tests are a set of standardized assessments carried out on power transformers to evaluate their performance characteristics and ensure they meet specific operational criteria under various conditions. These tests are typically performed once on a prototype transformer to verify that it operates according to the design specifications. The results are then used as a benchmark for production units, ensuring that all transformers produced exhibit similar reliability and performance.

Key Parameters Evaluated in Type Tests

1. Temperature Rise Test This test measures how much a transformer’s temperature rises under full-load conditions. It is critical for ensuring that the transformer can dissipate heat effectively without risking insulation breakdown or component failure over time.

2. Insulation Resistance Test This evaluation checks the quality of insulation materials used in the transformer. High insulation resistance indicates a lower chance of leakage currents, which helps prevent unexpected faults and prolongs the lifespan of the transformer.

3. Lightning Impulse and Switching Impulse Tests These tests are conducted to evaluate how well a transformer can withstand voltage surges caused by lightning strikes or operational switching events. These assessments are crucial for ensuring transformer durability and longevity.

4. Short-Circuit Test This test assesses a transformer’s ability to withstand fault conditions. It evaluates the mechanical and thermal stresses that a transformer can endure during short-circuit occurrences. This is important for minimizing damage when faults occur in the power system.

5. No-Load Loss and Load Loss Tests These measurements determine the energy losses in the transformer during operation. No-load loss occurs when the transformer is energized but not supplying load, while load loss is measured under loaded conditions. Understanding these losses is essential for calculating the transformer’s efficiency.

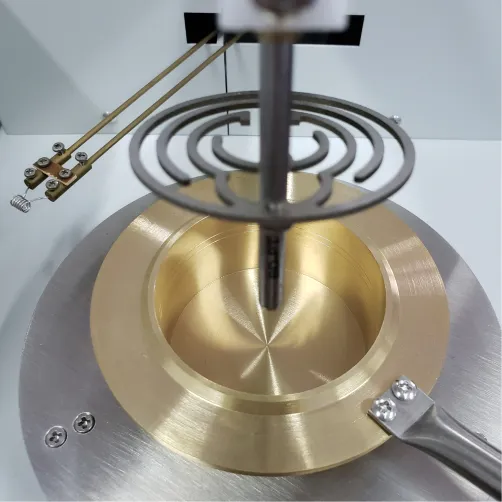

power transformer type test

6. Frequency Response Analysis This test evaluates a transformer’s response to various frequencies, helping to identify potential issues related to mechanical deformations or insulation failures.

Importance of Type Tests

Type tests are not just a regulatory formality; they are vital for several reasons

- Safety Assurance Ensuring that transformers meet safety standards helps prevent catastrophic failures that can lead to station outages or fire hazards.

- Reliability and Performance Type testing helps provide assurance of long-term performance and reliability, ensuring a continuous power supply in the grid.

- Standard Compliance These tests ensure transformers comply with international standards (e.g., IEEE, IEC), thus increasing confidence among utilities and customers.

- Quality Control Type tests serve as a fundamental quality control measure, ensuring that all units manufactured post-testing adhere to the performance standards established by the prototype.

Conclusion

Power transformer type tests are an essential part of transformer design and manufacturing. They play a critical role in ensuring that transformers are safe, reliable, and efficient. These tests provide valuable data that help manufacturers refine designs, improve production processes, and ensure that the end products will perform under the demands of the electrical grid. As power systems evolve, particularly with the integration of renewable energy sources and smart grid technologies, the importance of thorough type testing will only continue to grow, guaranteeing a robust and stable electrical infrastructure for the future.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025