English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

step down transformer testing

Testing Step-Down Transformers A Comprehensive Guide

Step-down transformers are essential components in various electrical systems, serving to reduce high voltage levels to safer, more manageable voltages. These transformers play a significant role in power distribution, allowing electricity to be used efficiently in residential, commercial, and industrial applications. As with any electrical device, the testing of step-down transformers is crucial to ensure their reliability, safety, and performance. This article will delve into the various testing methodologies and considerations involved in evaluating step-down transformers.

Understanding Step-Down Transformers

Before discussing testing methods, it’s important to understand what a step-down transformer does. This type of transformer decreases voltage while increasing current. For example, if a transformer steps down the voltage from 240 volts to 120 volts, it will double the current, maintaining power balance due to the principle of conservation of energy. These transformers are characterized by a higher number of turns in the primary coil compared to the secondary coil.

Types of Tests on Step-Down Transformers

Testing step-down transformers involves a variety of assessments to ensure they function correctly under different conditions. The key tests include

1. Visual Inspection The first step in testing involves conducting a thorough visual inspection of the transformer. This includes checking for physical damage, signs of overheating, and proper connections. Inspectors should look for oil leaks in oil-filled transformers and corrosion on terminals.

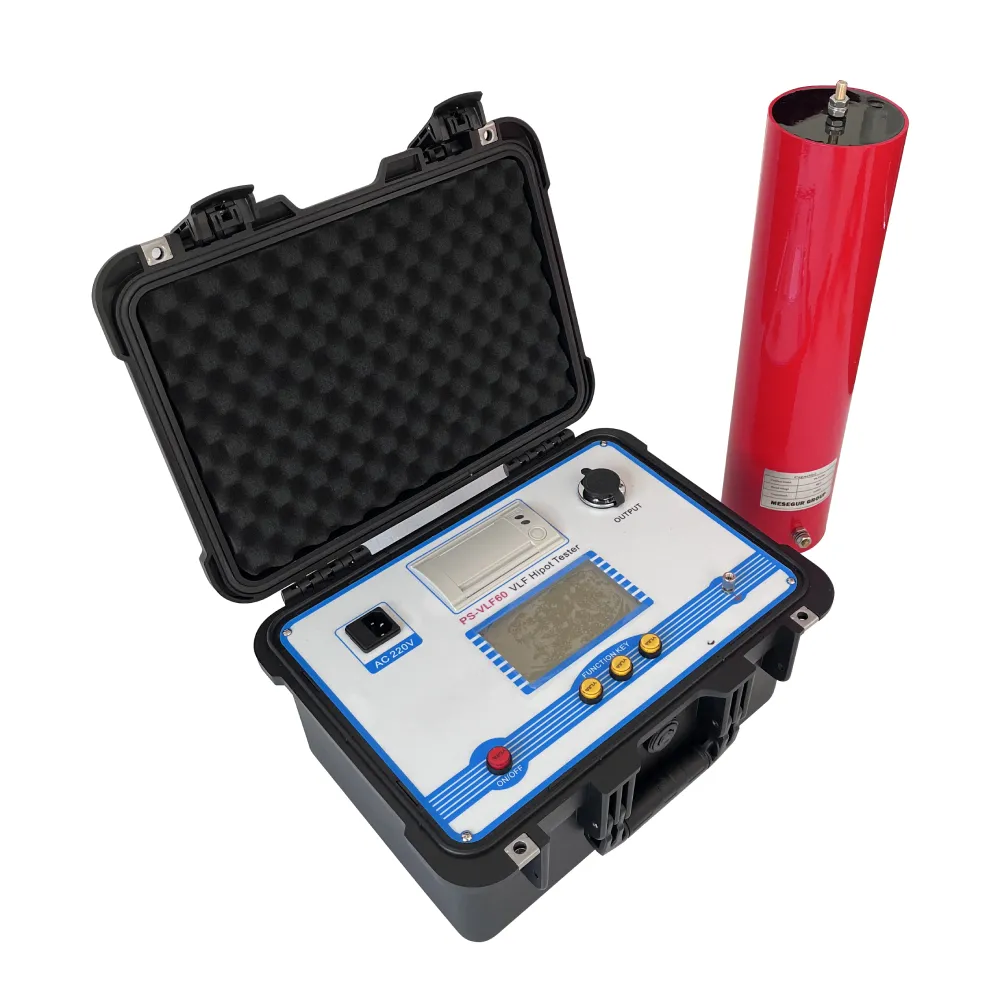

2. Insulation Resistance Testing This test measures the insulation resistance of the transformer windings against ground. Using a megohmmeter, technicians apply a high DC voltage to test for leakage currents, which can indicate insulation deterioration. A high insulation resistance value typically indicates good insulation quality.

3. Turns Ratio Testing This test verifies that the transformer turns ratio aligns with its design specifications. By applying voltage to the primary winding and measuring the secondary voltage, technicians can calculate the turns ratio. A significant deviation from expected values may indicate winding issues.

step down transformer testing

4. Load Testing Load testing assesses the performance of the transformer under operational conditions. It involves applying a known load to the secondary winding and measuring parameters such as voltage, current, and temperature. Load tests help identify potential overheating or voltage drop issues.

5. Temperature Rise Testing This test evaluates how well the transformer dissipates heat under load. By monitoring the temperature of the windings and other components during operation, engineers can determine whether the transformer operates within safe temperature limits, which is critical for longevity and reliability.

6. Short Circuit Testing This test helps assess the transformers' impedance and short-circuit current capabilities. By applying a short circuit to the output and measuring the resultant current, engineers can evaluate the transformer's ability to withstand fault conditions.

7. Power Factor Testing The power factor of a transformer indicates how effectively it converts electrical power. This test involves analyzing the phase differences between voltage and current to determine losses due to inefficiencies in the transformer.

Importance of Regular Testing

Regular testing of step-down transformers is vital for several reasons. Firstly, it ensures compliance with safety standards and regulations, protecting both personnel and equipment. Secondly, routine testing helps identify potential issues before they lead to catastrophic failures, thus minimizing downtime and costly repairs. Finally, consistent monitoring of transformer performance can optimize energy efficiency, contributing to cost-effective operations.

Conclusion

Testing step-down transformers is an indispensable process that ensures the safety, efficiency, and longevity of these critical electrical components. Through a combination of visual inspections, insulation resistance testing, load assessments, and various other methodologies, engineers can effectively evaluate the performance of transformers across their operational life. As technology evolves and the demand for reliable power supply increases, the importance of rigorous transformer testing will undoubtedly continue to grow, safeguarding both infrastructure and investment in the electrical grid.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025