English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Determining Current Limits for Hipot Testing Procedures and Safety Standards

Understanding Hipot Test Current Limit Importance and Implementation

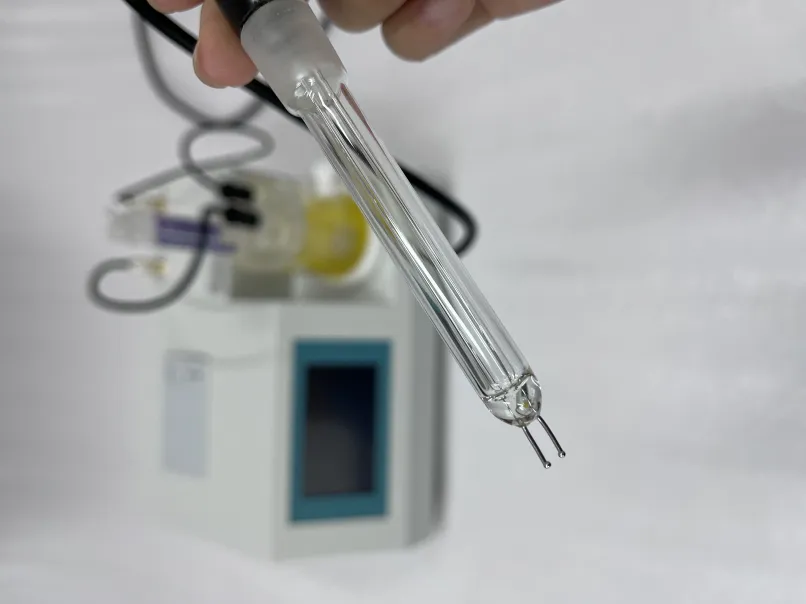

The hipot test, also known as insulation resistance testing or dielectric withstand testing, is a crucial procedure in the evaluation of electrical equipment's safety and performance. By applying a high voltage to the insulation of electrical devices, the hipot test ensures that insulation can withstand operational conditions and prevents electrical failures. A significant aspect of this test is the current limit, which serves as a pivotal factor in determining the reliability and safety of electrical devices.

What Is the Hipot Test?

The hipot test, derived from high potential, involves applying a predetermined high voltage to the insulated parts of an electrical device while the ground or uninsulated parts are connected to the ground. The primary purpose of this test is to assess the integrity of the insulation and to detect any potential weaknesses that could lead to electrical failure. By simulating extreme conditions, manufacturers can ensure that their products will perform safely in real-world scenarios.

Significance of the Current Limit

Setting an appropriate current limit for hipot tests is essential for several reasons

1. Safety Assurance By imposing a current limit during the hipot test, potential hazards such as electrical shocks can be minimized. The limit helps to ensure that any uncontrolled current flow does not exceed safe levels, which is critical when testing high-voltage equipment.

2. Test Accuracy Establishing a current limit enhances the reliability of the test results. A high current could indicate a breakdown in insulation; however, if the current flow exceeds predefined limits, it might trigger false readings that can lead to incorrect assessments of equipment safety.

3. Equipment Protection Electrical devices are designed to handle certain voltage levels. By imposing a current limit, potential damage to the equipment during testing can be avoided. Excessive current can generate heat, leading to insulation breakdown or physical damage to the components being tested.

hipot test current limit

4. Quality Control Industries that manufacture electrical components are under stringent regulatory scrutiny. Implementing a well-defined current limit adds to the credibility of the testing process, ensuring that products meet defined safety standards before they reach consumers.

Implementation of Current Limits in Hipot Testing

To effectively implement current limits during hipot testing, manufacturers often follow established guidelines and industry best practices

1. Referencing Standards Many industries refer to normative standards such as IEC 61010 or UL 508 to determine appropriate current limits. These standards provide guidelines on safe testing practices, ensuring compliance with safety regulations.

2. Calibration of Equipment Testing equipment must be regularly calibrated to ensure its accuracy. By maintaining the reliability of testing devices, manufacturers can ensure that the applied voltage and resulting current are accurately monitored.

3. Training Personnel Proper training for personnel conducting hipot tests is vital. Technicians must understand the significance of current limits and how to interpret the results accurately. This awareness helps prevent dangerous situations and ensures accurate evaluations.

4. Regular Maintenance Regular maintenance of testing apparatus is necessary to ensure that all components function correctly and that safety measures are in place. Routine checks can identify and mitigate any potential issues before they escalate.

Conclusion

The hipot test is an indispensable part of ensuring the safety and reliability of electrical devices, with the current limit playing a critical role in its success. By prioritizing current limits, manufacturers can protect both their equipment and the end-users of their products. As electrical standards continue to evolve, ongoing education and adherence to safety protocols will be paramount in maintaining high safety levels in the industry. Awareness of hypot testing and its current limit ensures that as technology progresses, so too does the commitment to consumer safety and product reliability.

-

Transformer Test Essentials: Insulating Oil Tester and TypesNewsMay.30,2025

-

Grease Testers and Oil Determination OverviewNewsMay.30,2025

-

Exploring Electricity Usage Testers and GeneratorsNewsMay.30,2025

-

Essential Guide to Transformer Oil Testing ToolsNewsMay.30,2025

-

Ensuring Safety with a Circuit Breaker FinderNewsMay.30,2025

-

Electrical Safety Tools Hipot, Dielectric, VLF TestersNewsMay.30,2025