English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

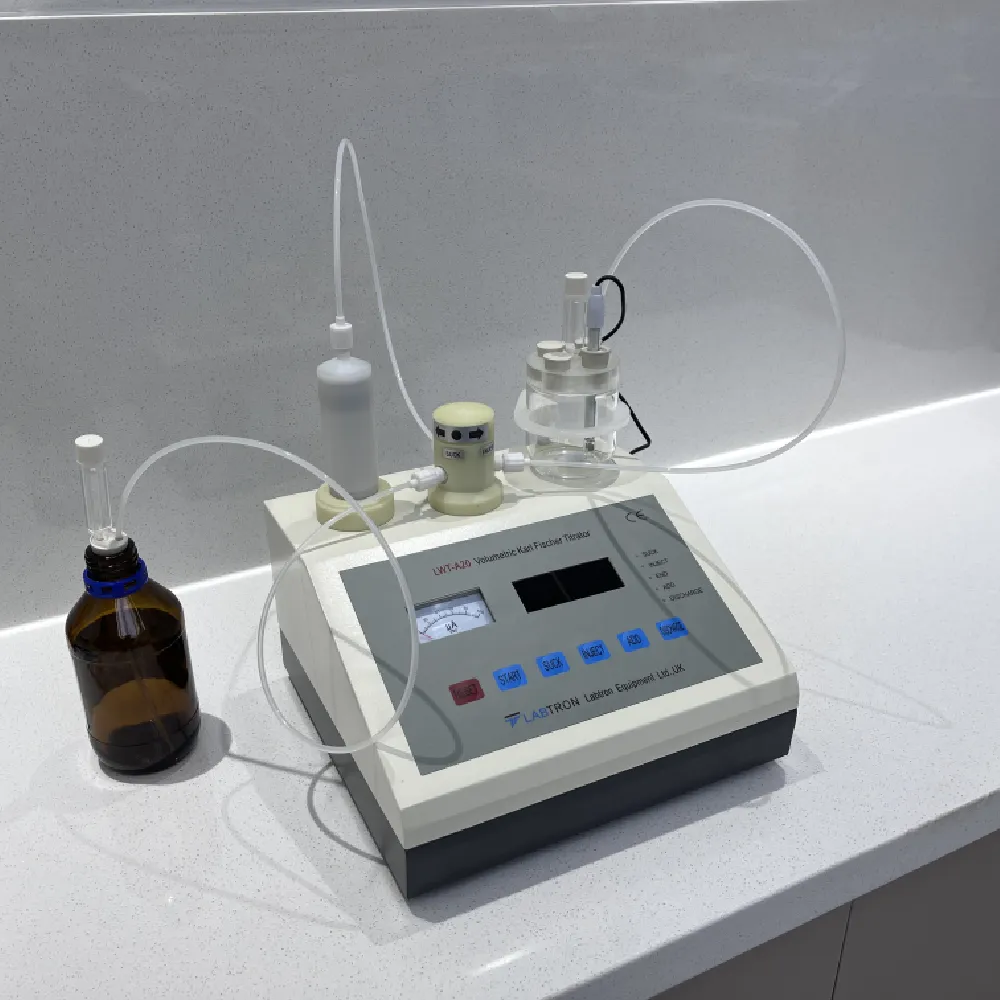

kinematic viscosity tester

Understanding Kinematic Viscosity Testers Importance, Functionality, and Applications

Kinematic viscosity is a critical physical property of fluids, reflecting their internal resistance to flow under the influence of gravity. It is a key parameter in various fields, including engineering, manufacturing, and environmental sciences. The measurement of kinematic viscosity is essential for understanding a fluid's behavior in both dynamic and static conditions, which can significantly impact performance in applications ranging from lubrication to hydrodynamics. To ascertain this property accurately, kinematic viscosity testers are employed.

What is Kinematic Viscosity?

Kinematic viscosity is defined as the ratio of dynamic viscosity to fluid density. It is typically measured in centistokes (cSt) and is crucial for assessing how a fluid will behave under different temperature and pressure conditions. The concept was introduced to simplify the understanding of fluid mechanics and provides a clearer picture of how various fluids will perform when subjected to gravitational forces.

Importance of Kinematic Viscosity Testers

Kinematic viscosity testers are specialized instruments designed to measure a fluid’s viscosity with precision. Their importance cannot be overstated, as they provide vital data that influences numerous industrial processes. For instance, in the petrochemical industry, kinematic viscosity measurements help in determining the quality of lubricating oils, which directly impacts engine performance and lifespan.

Furthermore, in the food and beverage sector, kinematic viscosity testers help ensure product consistency and quality. In pharmaceuticals, they play a significant role in formulating drugs where fluid properties can affect absorption and efficacy. Therefore, a reliable kinematic viscosity tester is essential for research and quality control across various industries.

Functionality of Kinematic Viscosity Testers

The functionality of kinematic viscosity testers is based on the principle of fluid flow through a calibrated capillary tube. The fluid’s viscosity is calculated by measuring the time it takes for a specific volume of the fluid to pass through the tube under controlled temperature conditions.

kinematic viscosity tester

Different designs of kinematic viscosity testers exist, including the Ubbelohde, Cannon-Fenske, and Ostwald methods

. Each design utilizes a capillary tube, but they differ in their construction and the specifics of how the flow is measured. For example, the Ubbelohde viscometer, often used for transparent liquids, can provide highly accurate measurements by eliminating end effects that can skew results.Modern kinematic viscosity testers incorporate digital interfaces and automated systems that enhance measurement accuracy and speed. Advanced models offer temperature control and data logging capabilities, allowing users to conduct multiple tests efficiently and record results for analysis.

Applications of Kinematic Viscosity Testers

The applications of kinematic viscosity testers are virtually limitless, extending across many sectors. In automotive engineering, these testers are crucial for ensuring that oils adhere to specific viscosity grades appropriate for various engine types and conditions.

In the aerospace industry, kinematic viscosity measurement plays a significant role in fuel selection, which affects performance and safety. Additionally, in environmental sciences, understanding the viscosity of oils in water bodies aids in oil spill response and planning effective remediation strategies.

Moreover, as industries move towards sustainability, kinematic viscosity testing is becoming increasingly important in the evaluation of biofuels and alternative lubricants, which often exhibit different flow characteristics compared to traditional petroleum-based products.

Conclusion

In summary, kinematic viscosity testers are indispensable tools for accurately measuring fluid viscosity. Their ability to provide reliable data is fundamental for industrial applications across diverse sectors, fostering quality control, safety, and innovation. As technology continues to advance, the evolution of these testers will likely enhance measurement precision and expand their applications, addressing the growing complexity of modern fluid systems. Ultimately, the role of kinematic viscosity testers is pivotal in optimizing performance and ensuring the integrity of products that rely on fluid mechanics.

-

Transformer Test Essentials: Insulating Oil Tester and TypesNewsMay.30,2025

-

Grease Testers and Oil Determination OverviewNewsMay.30,2025

-

Exploring Electricity Usage Testers and GeneratorsNewsMay.30,2025

-

Essential Guide to Transformer Oil Testing ToolsNewsMay.30,2025

-

Ensuring Safety with a Circuit Breaker FinderNewsMay.30,2025

-

Electrical Safety Tools Hipot, Dielectric, VLF TestersNewsMay.30,2025