English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Laboratory Applications and Innovations in Distillation Units for Chemical Separation

Understanding the Distillation Unit in Laboratory Settings

Distillation is a widely used separation technique in laboratories, essential for purifying liquids and separating components based on differences in their boiling points. A distillation unit serves as the core apparatus in these processes, allowing chemists and researchers to conduct efficient and precise distillations. This article delves into the functioning, types, and applications of distillation units in laboratory environments.

Components of a Distillation Unit

A standard distillation unit typically includes several key components the distillation flask, heat source, condenser, receiving flask, and thermoregulator. The distillation flask is where the mixture to be separated is heated. A heat source, which may be electrical or a Bunsen burner, gradually elevates the temperature of the liquid in the distillation flask.

As the mixture is heated, the component with the lowest boiling point vaporizes. This vapor travels through the condenser, where it cools and condenses back into liquid form. The cooled liquid then drips into the receiving flask, where it is collected. Throughout the distillation process, a thermoregulator may be used to monitor and maintain the temperature, ensuring that the desired component vaporizes at the right time.

Types of Distillation

In a laboratory, several types of distillation can be employed depending on the nature of the mixture and the separation requirements

1. Simple Distillation This method is ideal for separating substances with significantly different boiling points (generally more than 25 degrees Celsius apart). It is commonly used for purifying solvents or for removing impurities from liquids.

2. Fractional Distillation When dealing with mixtures where components have closer boiling points, fractional distillation is more effective. This process utilizes a fractionating column, allowing for multiple vaporization and condensation cycles, which enhances separation efficiency.

3. Vacuum Distillation This variation is employed when dealing with heat-sensitive compounds or those with very high boiling points. By reducing the pressure in the distillation unit, the boiling points of the components decrease, preventing thermal decomposition.

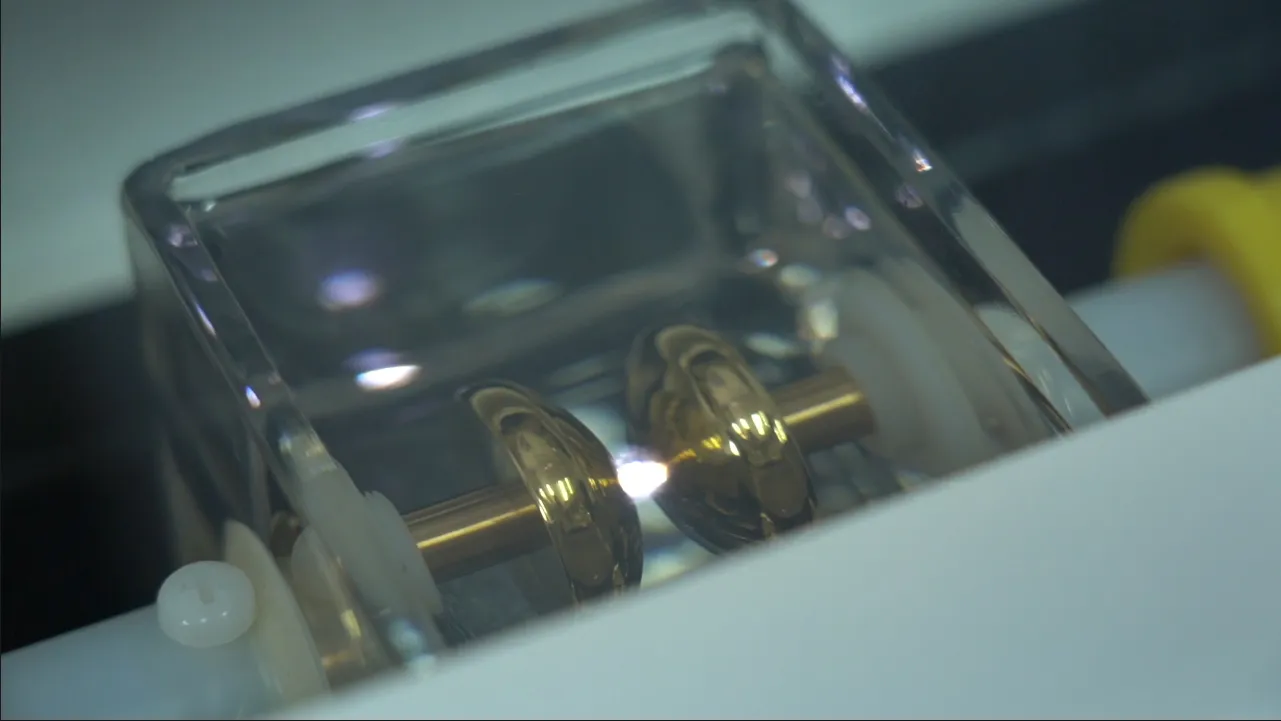

distillation unit in laboratory

Applications in Laboratories

Distillation units are indispensable in various laboratory applications across different fields

- Chemical Research In chemistry, distillation is used to purify solvents, separate reaction by-products, and characterize compounds based on their boiling points. It’s also crucial in synthesizing high-purity chemicals.

- Pharmaceuticals The pharmaceutical industry relies on distillation for the purification and formulation of drugs, ensuring that active ingredients are free from contaminants.

- Environmental Testing Distillation is employed in environmental laboratories to analyze samples for pollutants. It can help isolate specific compounds from water or soil samples for further study.

- Food and Beverage Industry Distillation is used in the production of spirits and essential oils, as well as in analyzing food samples to detect volatile substances.

Conclusion

The distillation unit is a vital piece of equipment in any laboratory setting, enabling researchers to achieve precise separations and purifications. Understanding the intricacies of distillation, its various methods, and its multitude of applications enhances its effective utilization. As technology advances, these units continue to evolve, incorporating more sophisticated controls and measurement techniques, ultimately leading to more efficient and accurate distillation processes in laboratories worldwide.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025