English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Testing Partial Discharge in Current Transformers for Enhanced Performance and Reliability

Partial Discharge Test of Current Transformers An Overview

Current transformers (CTs) are essential components in electrical power systems, serving to transform high currents into lower, manageable levels while maintaining accuracy for measurement and protection purposes. However, like all electrical equipment, CTs are vulnerable to insulation failures, which can lead to severe operational disruptions and safety hazards. One critical method for assessing the health of a current transformer is the Partial Discharge (PD) test. This article explores the significance, methodology, and interpretation of PD tests in the context of current transformers.

Understanding Partial Discharge

Partial discharge refers to the localized dielectric breakdown of insulation materials. It occurs within an insulation system when the electric field strength exceeds the material's dielectric strength, but it does not result in a complete insulation failure. PD can occur in solid, liquid, or gaseous insulation and is often symptomatic of insulation deterioration, which may eventually lead to catastrophic failure if unchecked.

In current transformers, partial discharges can arise from imperfections in the insulation, such as voids, cracks, or impurities. The occurrence of PD signals potential weaknesses in the insulation that need to be monitored and addressed to ensure the long-term reliability of the transformer.

Importance of PD Testing

Performing PD tests on current transformers is critical for several reasons

1. Condition Assessment Regular PD testing allows engineers to assess the condition of the insulation within CTs. By identifying and quantifying PD activity, operators can gauge the likelihood of insulation failure.

2. Preventative Maintenance Early detection of insulation problems through PD measurements enables operators to take corrective actions before a significant failure occurs. This proactive approach can save costs and reduce the risk of unexpected outages.

3. Regulatory Compliance Many industries and jurisdictions require regular testing of electrical equipment to ensure compliance with safety and reliability standards. Partial discharge testing can help meet these regulatory requirements.

4. Performance Optimization Understanding the insulation condition through PD testing can help optimize the operation and performance of current transformers, thereby improving overall system reliability.

Methodology of PD Testing

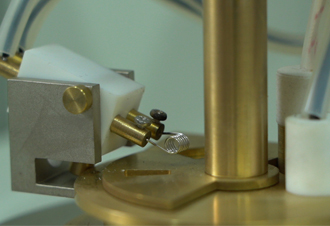

partial discharge test of current transformer

The PD testing of current transformers involves several key steps

1. Test Equipment Setup Specialized equipment is used to detect and measure PD activity. This includes PD detectors, high-frequency current transformers, and oscilloscopes.

2. Test Protocol The current transformer is subjected to a voltage stress, often at a level above its normal operating voltage, to induce partial discharge phenomena. The testing is typically performed under controlled conditions to ensure accurate readings.

3. Data Collection The PD activity is monitored and recorded throughout the test. Data is collected in the form of pulse sizes, frequencies, and patterns, which are indicative of the insulation condition.

4. Analysis The collected data is analyzed using established criteria to determine the severity of the detected partial discharges. Factors such as the magnitude and repetitive nature of PD pulses can indicate the likelihood of insulation failure.

Interpreting PD Test Results

Interpreting PD test results requires a thorough understanding of the electrical environment and the properties of the current transformer under test. A low level of PD activity is generally acceptable, but increasing levels or a marked change from baseline measurements can be cause for concern.

The results are often classified into three categories

- Acceptable Little or no PD activity is detected, indicating good insulation integrity. - Caution Some PD activity is observed, suggesting potential issues that need monitoring over time. - Action Required High levels of PD activity are detected, necessitating immediate investigation and possible intervention.

Conclusion

The partial discharge test is a vital tool in the maintenance and operation of current transformers. By identifying insulation weaknesses early on, operators can ensure the reliability and longevity of their electrical systems. As technology advances, the methods and tools for PD testing continue to improve, enhancing our ability to understand and mitigate risks associated with insulation failures. In a world that increasingly relies on stable and efficient electrical power, the role of PD testing in current transformers cannot be overstated. Regular PD assessments are an investment in the safety and reliability of electrical infrastructure, ultimately safeguarding both equipment and operational continuity.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025