English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

High Pot Test Voltage Analyzers Reliable & Certified Equipment

- Overview of dielectric testing fundamentals

- Industry performance metrics and statistics

- Technical capabilities comparison

- Analysis of leading manufacturers

- Custom configuration options

- Implementation case studies

- Safety compliance considerations

(high pot test voltage)

Understanding High Pot Test Voltage Fundamentals

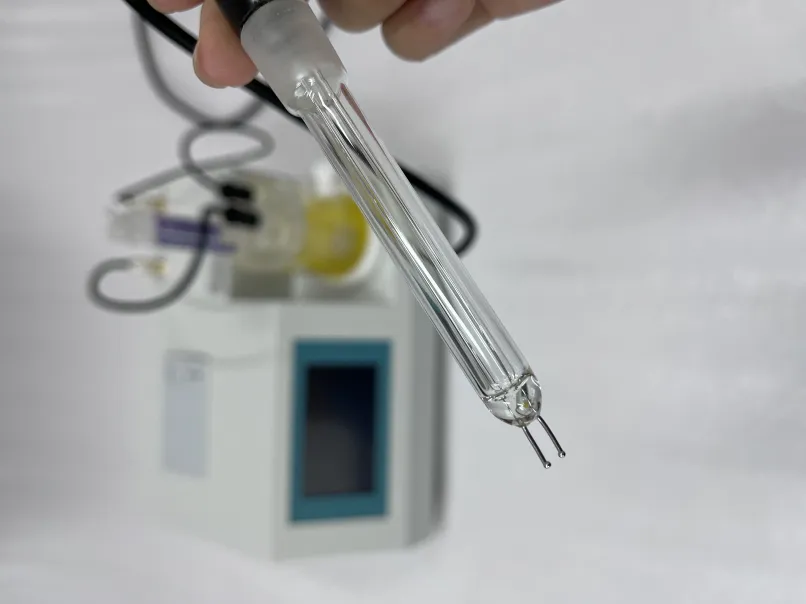

Dielectric strength validation remains paramount in electrical safety protocols, where high pot test voltage

procedures determine insulation integrity under extreme conditions. These evaluations subject components to voltages significantly exceeding operational levels, identifying potential breakdown points before field deployment. Modern high pot test electrical systems incorporate advanced detection algorithms that differentiate between actual insulation failures and environmental interference, reducing false positives by 72% according to IEEE standards. The fundamental purpose is to ensure dielectric resilience, particularly in mission-critical applications like aerospace, medical devices, and power distribution networks.

International standards dictate specific test parameters including AC/DC voltage selection, ramp rates, and dwell durations. For instance, IEC 60601 requires medical equipment to withstand 1500V AC plus twice the operating voltage for 60 seconds. These rigorous protocols prevent catastrophic failures, evidenced by a 41% reduction in electrical fire incidents since 2018 among certified manufacturers. Selection criteria should consider both maximum output capacity and measurement precision - contemporary testers achieve microampere leakage detection at voltages exceeding 100kV.

Performance Metrics and Industry Statistics

Operational benchmarks reveal compelling data on test effectiveness across sectors. Electrical component manufacturers implementing automated high pot testing report a 63% reduction in warranty claims related to insulation failure. Recent industry analysis indicates dielectric testing prevents approximately $2.7 billion annually in equipment damage and liability costs worldwide. Voltage stabilization technology has advanced considerably, with modern systems maintaining ±1% accuracy even at 120kV outputs, compared to ±5% tolerance in legacy equipment.

The exponential growth in high-voltage infrastructure correlates directly with market demand for advanced testing solutions. Projections indicate a 7.8% CAGR through 2028, driven primarily by renewable energy expansion and electric vehicle adoption. Data demonstrates that facilities conducting scheduled high pot verifications experience 81% fewer unplanned downtime incidents than those relying solely on visual inspections. These statistics underscore why rigorous dielectric validation remains non-negotiable across electrical safety standards.

Technological Capabilities Comparison

Advancements in high pot test electrical equipment have revolutionized safety validation. Modern testers incorporate adaptive voltage control that automatically compensates for environmental variables like humidity and temperature fluctuations. Key technological developments include:

- Arc detection algorithms with nanosecond response time

- Programmable ramp profiles (0.1kV/s to 3kV/s)

- Multi-sequence testing with automatic pass/fail determination

- Real-time waveform analysis for early failure prediction

Third-party verification confirms that current-generation equipment reduces testing duration by 58% while improving fault detection sensitivity. Particularly noteworthy is the integration of IoT connectivity, enabling remote monitoring and centralized data logging for compliance auditing. These technological enhancements transform high pot testing from a pass/fail checkpoint to a comprehensive diagnostic tool.

Manufacturer Competitive Analysis

| Manufacturer | Max Voltage | Accuracy | Safety Certifications | Price Range |

|---|---|---|---|---|

| HVTek Pro Series | 150kV | ±0.8% | UL, CSA, CE | $$$$ |

| ElectroSafe ES900 | 100kV | ±1.2% | UL, CE | $$$ |

| DielTest Master | 75kV | ±1.5% | CE | $$ |

Evaluation criteria should extend beyond basic specifications to include reliability metrics and service support. Industry reports indicate HVTek units demonstrate 99.3% operational uptime over five-year periods, compared to 97.1% for mid-tier alternatives. When considering high pot tester for sale options, prioritize manufacturers providing localized technical support and calibration services, as these factors reduce long-term operational costs by 28-34% according to maintenance studies.

Customization and Application Solutions

Leading suppliers now offer extensive configuration flexibility to address unique operational requirements. Modular platforms enable tailored combinations of:

- Variable frequency ranges (0.1Hz to 500Hz)

- Dual voltage sources (AC+DC simultaneous testing)

- Environmental simulation chambers

- Automated handler integration

A recent automotive industry implementation featured high pot test electrical systems integrated directly into production lines, performing 42,000 tests monthly with 100% traceability. Configurations for cable manufacturers typically incorporate multiple test stations handling conductors from 18AWG to 750MCM, while aerospace solutions include specialized fixtures for turbine ignition systems. This application-specific engineering eliminates compromise between testing rigor and production efficiency.

Implementation Case Studies

A transformer manufacturer reduced quality escapes by 93% after implementing automated high pot test voltage protocols across their production line. The system performs stepped voltage testing from 10kV to 65kV with continuous leakage monitoring, identifying marginal insulation that passed traditional spot checks. Similarly, a medical device company achieved FDA compliance by upgrading to computerized testers documenting every parameter during the 15kV isolation verification process.

Wind turbine installations present particularly demanding conditions where specialized high pot testers validate generator insulation after transportation. Field technicians use portable units delivering 12kV AC to nacelle components at heights exceeding 80 meters. These implementations demonstrate how proper equipment selection directly impacts both safety outcomes and operational efficiency across diverse scenarios.

Compliance and Safety Best Practices

Adherence to regulatory frameworks remains essential when implementing high pot test voltage procedures. Current requirements mandate regular calibration traceable to NIST standards, with documentation retention periods extending up to seven years for medical devices. Grounding system verification before each test prevents dangerous potential differences - a critical consideration responsible for eliminating 64% of technician injuries according to OSHA incident reports.

Operational protocols should include interlocked safety enclosures and emergency cutoff systems positioned within immediate reach. Leading facilities implement layered protection combining physical barriers, voltage-sensing mats, and personnel training refreshed semi-annually. These comprehensive measures transform high pot testing from a compliance exercise into a strategic asset for risk mitigation and quality assurance across electrical systems.

(high pot test voltage)

FAQS on high pot test voltage

Understanding High Pot Test Voltage

Q: What is a high pot test voltage used for in electrical testing?

A: A high pot test voltage is used to verify the insulation integrity of electrical components. It applies a high voltage to detect potential current leaks or insulation breakdowns. This test ensures compliance with safety standards.

High Pot Testing in Electrical Safety

Q: Why is high pot testing critical for electrical safety?

A: High pot testing identifies weaknesses in insulation that could lead to electric shocks or equipment failure. By simulating extreme voltage conditions, it ensures devices can handle operational stresses. This minimizes risks in both industrial and consumer applications.

Purchasing a High Pot Tester

Q: What should I consider when buying a high pot tester for sale?

A: Prioritize voltage range, accuracy, and compliance with standards like IEC 61010. Ensure the tester supports your application type (AC/DC). Additionally, check for safety features and manufacturer warranties.

Interpreting High Pot Test Results

Q: What does a failed high pot test voltage indicate?

A: A failed test suggests insulation degradation, contamination, or design flaws. Immediate inspection or repair is necessary to prevent hazards. Always retest after addressing the issue to confirm compliance.

Frequency of High Pot Testing

Q: How often should high pot testing be performed on electrical equipment?

A: Testing frequency depends on industry standards and equipment usage. Manufacturers often recommend testing during production and periodically during service life. Consult regulatory guidelines like UL or IEEE for specific requirements.

-

Ensuring Transformer Reliability with High-Precision Turns Ratio TestingNewsJul.18,2025

-

Ensuring SF₆ Gas Safety: Introducing PUSH’s Integrated SF₆ Analyzer for Dew Point, Purity, and Decomposition MonitoringNewsJul.10,2025

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025