English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Induced Voltage Testing Methods for Transformer Performance Evaluation and Safety Assessment

Induced Voltage Test of Transformers An Overview

The induced voltage test, also known as the high-voltage test, is an essential diagnostic procedure used to assess the insulation integrity of transformers. It ensures that the transformer can withstand operating voltages and conditions without any breakdown or failure. This testing is critical in both the manufacturing stage and the maintenance of transformers throughout their service life.

Purpose of Induced Voltage Testing

The primary purpose of the induced voltage test is to evaluate the dielectric strength of the insulation within the transformer. Insulation failure can lead to catastrophic equipment failure, circuit disruptions, and even hazards such as electrical fires. The induced voltage test simulates the electrical stresses the transformer will face during normal operation, allowing engineers to identify potential weaknesses in the insulation system before the transformer is deployed in the field.

Testing Procedure

The induced voltage test is conducted by applying a voltage that is higher than the transformer’s rated voltage. Typically, this voltage is applied to the primary winding while the secondary winding is left open. The voltage is gradually increased to a predetermined level, often up to 2 to 3 times the rated voltage, based on specific industry standards and manufacturer's recommendations. The duration of the test is usually around one minute, although this can vary depending on the requirements.

As the induced voltage is applied, the transformer is monitored for any signs of stress or failure, such as current leakage, arcing, or unusual sounds. After the test, it is crucial to measure the insulation resistance using a megohmmeter. A high insulation resistance value indicates that the transformer’s insulation is in good condition, while a low value could suggest potential issues that need further investigation.

Safety Considerations

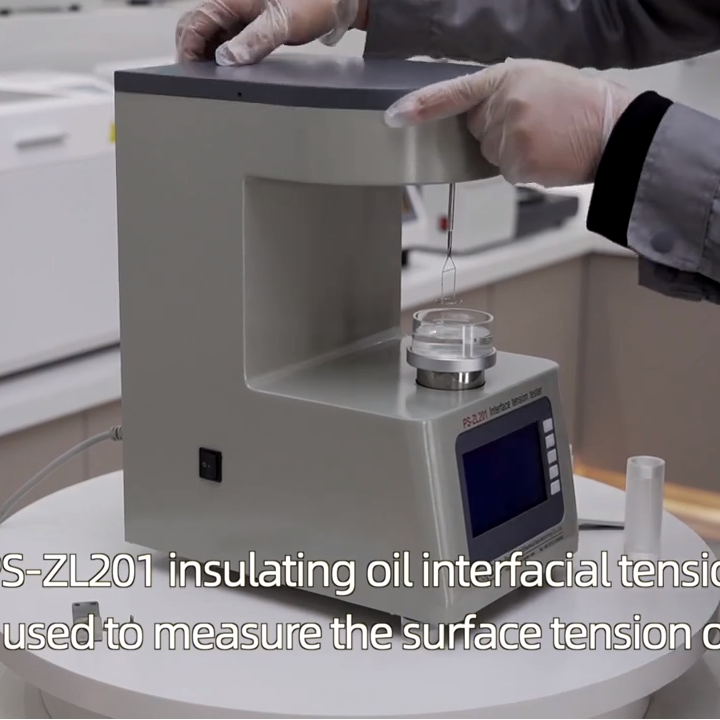

induced voltage test of transformer

Safety is paramount during the induced voltage test, as high voltages can pose significant hazards to personnel and equipment. Proper grounding and safety measures should be implemented to protect workers from electrical shock. Additionally, only trained professionals should conduct these tests, using appropriate personal protective equipment (PPE) and following established safety protocols to mitigate risks.

Advantages of Induced Voltage Testing

1. Predictive Maintenance The induced voltage test helps in identifying insulation weaknesses before they lead to failure, facilitating effective predictive maintenance strategies. 2. Quality Assurance For manufacturers, this test ensures that transformers meet quality standards and can operate safely and efficiently under normal conditions. 3. Cost-Efficiency By detecting potential insulation failures early, organizations can avoid costly repairs or replacements that might occur if failures happen during operation.

4. Compliance Many industry standards and regulations require periodic testing of transformers, and the induced voltage test helps ensure compliance with these mandates.

Limitations

While the induced voltage test is beneficial, it is not without limitations. The test does not directly assess the condition of all components within the transformer. For example, mechanical faults, core issues, or problems in other electronic components will not be detected by this test alone. As such, it should be part of a comprehensive maintenance program that includes various testing methods, such as power factor testing, insulation resistance testing, and thermal imaging.

Conclusion

The induced voltage test of transformers is a critical procedure for ensuring the reliability and safety of these vital components in electrical systems. By thoroughly assessing the insulation integrity and dielectric strength, utilities and manufacturers can avoid unexpected failures and extend the lifecycle of transformers. As the industry continues to evolve, advances in testing technologies and methodologies will further enhance our ability to maintain and operate these essential devices effectively. Ultimately, prioritizing such tests is crucial in maintaining the efficiency and reliability of power delivery systems worldwide.

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025

-

Digital Circuit Breaker Analyzer Features and BenefitsNewsJun.05,2025

-

Benefits of Real-Time Power Quality Monitoring Devices for Industrial EfficiencyNewsJun.05,2025

-

Earth Fault Loop Testing in High-Rise Building Electrical SystemsNewsJun.05,2025