English

English

-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

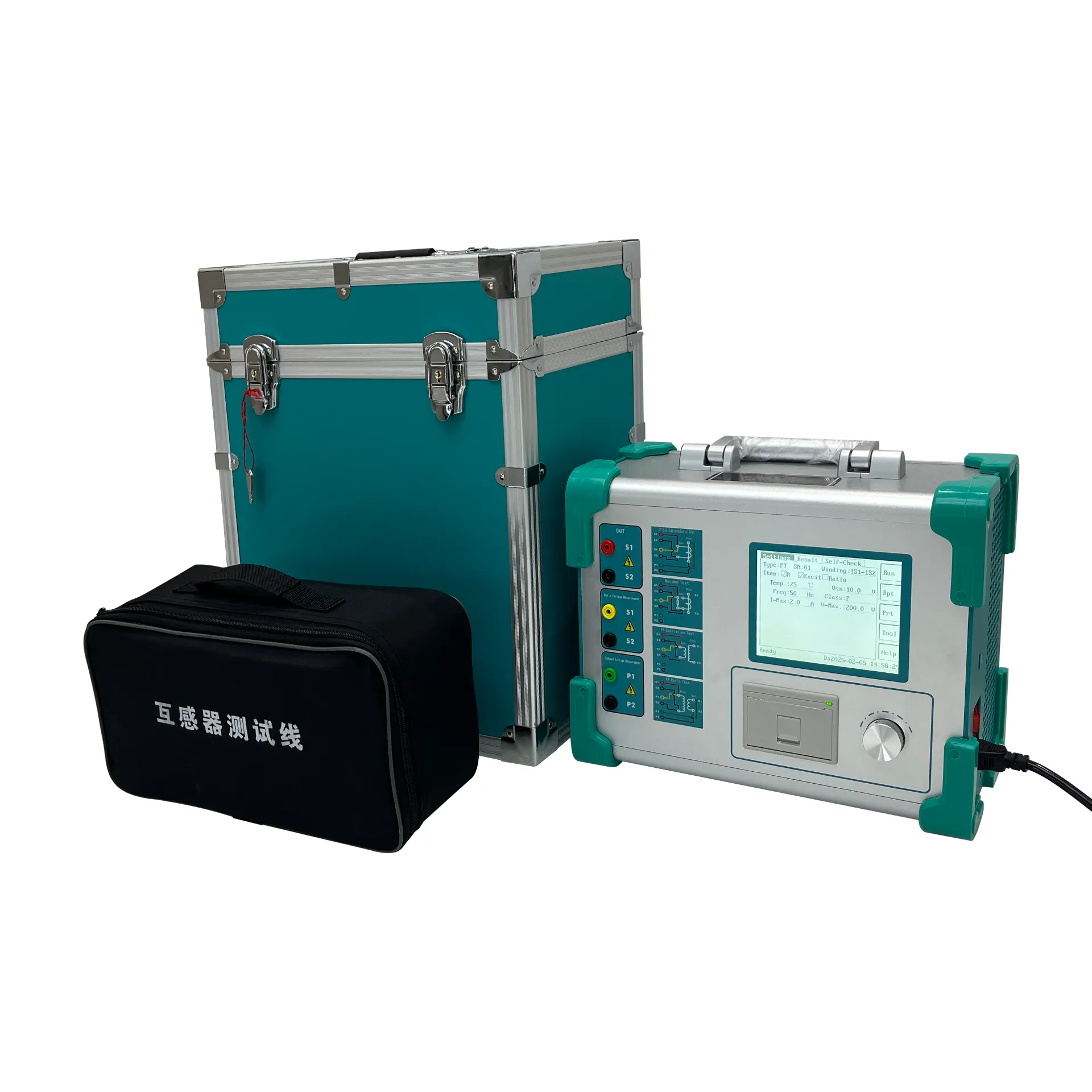

High-Precision CT PT Test Equipment for Reliable Power Analysis

As electrical power systems demand higher reliability and safety, CT PT test technologies have become the critical pillar for ensuring the accuracy and protection of measurement circuits. This article provides an in-depth overview of trends, technology parameters, real case studies, and in particular, spotlights the Transformer ct pt comprehensive characteristics tester (ct pt test)—a high-end solution meeting the most rigorous international standards.

Industry Trends of CT & PT Testing

- Digitalization & Automation: Growing adoption of smart grid and IoT integration, with remote diagnosis and real-time data acquisition contributing to predictive maintenance models.[1]

- International Standards: Compliance with IEC 61869, ANSI/IEEE C57.13 has become mandatory for large-scale transmission and distribution projects.[2]

- High Precision & Multi-functionality: Modern ct pt testing equipment integrates multiple modules (accuracy, polarity, ratio, excitation) and supports both CT PT tester and CT PT analyzer duties in a single device.

- Environmental Adaptability: Solutions are optimized for harsh conditions, including high humidity, extreme temperatures, and exposure to corrosive atmospheres such as petrochemicals or metallurgy.

- Eco-friendly Manufacturing: Use of RoHS-compliant and recyclable materials is on the rise, in line with global ESG initiatives.

CT PT Test: Key Parameters & Comparison

| Parameter | CT PT Test | CT PT Tester | CT PT Analyzer | Transformer CT Testing |

|---|---|---|---|---|

| Test Voltage Range | 5V~2500V | 0~2000V | Up to 2500V | 10V~2000V |

| Current Measurement Range | 1mA~6000A | 10mA~5000A | 1mA~6000A | 10mA~5000A |

| Accuracy Class | 0.1%~0.2% | 0.2%~0.5% | 0.1% | 0.2% |

| Load Resistance Range | 0.1Ω~50kΩ | 1Ω~20kΩ | 0.1Ω~30kΩ | 1Ω~10kΩ |

| Frequency Range | 45Hz~65Hz | 45Hz~65Hz | 40Hz~70Hz | 45Hz~60Hz |

| Standards Compliance | ISO, IEC, ANSI | IEC, ANSI | IEC, IEEE | IEC, ANSI |

Product Spotlight: Transformer ct pt comprehensive characteristics tester

The Transformer ct pt comprehensive characteristics tester (ct pt test) is a cutting-edge solution engineered for on-site and laboratory testing of current and potential transformers. Integrating functions such as excitation curve testing, ratio & polarity, secondary circuit diagnostics, and burden measurement, it ensures compliance with ISO 9001:2015, IEC 61869-2, and ANSI/IEEE C57.13 standards.

Raw Material Selection

High-purity copper

aircraft-grade aluminum

Precision CNC Machining

Micro-tolerance (±0.02mm)

3D/5-axis CNC

Assembly & Soldering

RoHS flux, ISO assembly lines

Anti-corrosion coating

Quality Assurance

Multi-step ISO & ANSI tests

Lifetime burn-in

Each step follows global industrial ct pt testing equipment standards, with process traceability and 100% final product inspection.

Technical Specifications Table

| Item | Specification |

|---|---|

| Test Module | CT excitation, PT excitation, Ratio & Polarity, Burden, Phase Angle |

| Output Voltage | 0~2500V (Automatic) |

| Output Current | 0~20A (Short-time) |

| Accuracy | ±0.1% (FS) |

| Frequency | 45Hz~65Hz |

| Display | 7-inch Touch-screen / USB export |

| Dimensions | 353 × 256 × 150 mm |

| Weight | 9.8 kg |

| Environment | -10°C ~ +45°C, Relative humidity <90% |

| Standard | IEC 61869, ANSI/IEEE C57.13, ISO 9001 |

Advantages and Differentiation

- Robust Materials: Casing of industrial ABS+aluminum alloy for long life (20,000+ test cycles); gold-plated terminals (corrosion resistance).

- Smart Diagnostics: Real-time waveform and test data, touch-screen interface, and full digital output minimize reliance on manual calculation.

- Wide Compatibility: Supports all classes of CT/PT (metering, protection), both wound and bar types, making it ideal for ct and pt testing and pt transformer testing.

- Data Security: Multi-level password, automatic report backup, and trouble/event log per ISO 27001.

- Easy Customization: OEM/ODM available — support for unique customer protocols and labeling.

Product Comparison Table

| Feature | Transformer CT PT Comprehensive Tester | Competitor A (G*** Brand) | Competitor B (V** Analyzer) |

|---|---|---|---|

| Voltage Range | 0~2500V | 0~2000V | Up to 1800V |

| Accuracy | ±0.1% | ±0.2% | ±0.15% |

| Touch-screen UI | Yes (7-inch) | No (LCD) | 4.3-inch (Basic) |

| Test Modules | CT/PT excitation, ratio, polarity, burden, phase | CT only | CT/PT (no burden test) |

| Weight | 9.8kg | 11kg | 13kg |

| Report Export | USB / Print / SD | USB only | None |

| Warranty | 36 Months | 24 Months | 12 Months |

| Compliance | IEC/ISO/ANSI | IEC | IEC |

Manufacturing Process Flow (with Infographics)

- Material Selection: Sourcing high-purity copper conductors, flame retardant self-healing ABS shells, and RoHS-certified PCBs. Ensures lifetime electrical safety and anti-interference.

- CNC Precision & Soldering: Internal parts CNC-machined to +/-0.02mm; robotic soldering lines reduce operator error and enhance component durability.

- ISO 9001 Assembly: Modular assembly lines reduce contamination risks. Insulation and HV tests at each node (in line with IEC 61869).

- Final QC: Routine (OTDR), impulse, and load cycle tests. Burn-in at 55°C for 72h ensures operational reliability.

Applications and Case Studies

- Electric Utilities: T&D substations, 66kV~765kV grids (India Power Grid, China State Grid, Siemens Energy)

- Metallurgy: Arc furnace CT verification in steel plants (POSCO, Baosteel)

- Petrochemical Pipelines: Explosion-proof PT transformer testing — compliant with FM/CE safety standards

- Water & Wastewater: Power quality monitoring in pumping stations; improved fault detection and rapid restart after grid events.

"We reduced substation downtime by 22% thanks to automated ct pt test reports—no more operator errors." — Sr. Engineer, ASEAN Hydropower

Technical FAQs: CT PT Test Equipment

Frequently Asked Questions

-

What materials are used in the CT PT testers?

Industrial-grade ABS + anodized aviation aluminum, oxygen-free copper terminals (for minimum resistance), RoHS/REACH compliant electronics. -

What accuracy class can be achieved?

The tester delivers up to 0.1% accuracy, meeting IEC 61869-2 / ANSI C57.13 requirements for protection and metering CTs and PTs. -

Which standards must be followed during installation?

All installations comply with IEC 61869, IEEE C57.13, ISO 9001. Calibration/commissioning requires certified test personnel. -

What size and weight does the device have?

Compact: 353x256x150mm, net weight 9.8kg. Ruggedized for field and lab environments. -

How is the test data stored and exported?

Reports saved to SD card/USB, security protected. Automatic backup, PDF/Excel export supported. -

What is the typical operation life of the equipment?

Over 20,000 test cycles; casing and PCBs are endurance-tested (IEC60068). -

What after-sales support is provided?

3-year warranty, 48-hour global response, calibration service (ISO17025 lab), continuous firmware upgrades.

Delivery, Warranty & Service Commitment

- Delivery: Custom models: 22~35 working days; standard models ex-stock. All shipments are compliance-packed and insured.

- Warranty: 36 months standard; lifetime online technical support.

- Customer Support: 48h max response time, local engineer site support in 16 countries.

- Compliance: Products are factory certified to ISO 9001, IEC, and ANSI/IEEE protocols; calibration to NIST/DAkkS/CEEMS traceability.

Citations & Recommended Reading

- IEC 61869 Standard Details, IEC Webstore

- IEEE Committee on Instrument Transformers: https://ieeexplore.ieee.org/document/8885424

- Review: Trends and Technologies in Electric Power Measurement, Electrical India Journal

- Industrial Forums Discussion: CT & PT Test Equipment Experiences, Eng-Tips Forum

- Market Report: Current Transformers & Potential Transformers Market, Fortune Business Insights

-

Ensuring Transformer Reliability with High-Precision Turns Ratio TestingNewsJul.18,2025

-

Ensuring SF₆ Gas Safety: Introducing PUSH’s Integrated SF₆ Analyzer for Dew Point, Purity, and Decomposition MonitoringNewsJul.10,2025

-

Exploring the Main Types of Industrial Endoscopes and Their Applications Across IndustriesNewsJul.04,2025

-

Testing Equipment Industry Sees Major Advancements in 2025: Smart & Precision Technologies Lead the WayNewsJun.06,2025

-

Applications of Direct Current Generators in Renewable Energy SystemsNewsJun.05,2025

-

Hipot Tester Calibration and Accuracy GuidelinesNewsJun.05,2025